Gas flow uniform-distributing device for selective catalytic reduction (SCR) denitration

A technology of airflow uniform distribution and reduction method, which is applied in chemical instruments and methods, separation methods, and dispersed particle separation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in detail in conjunction with the accompanying drawings.

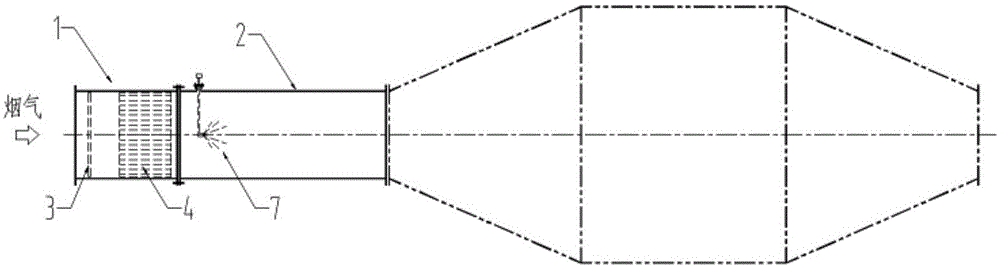

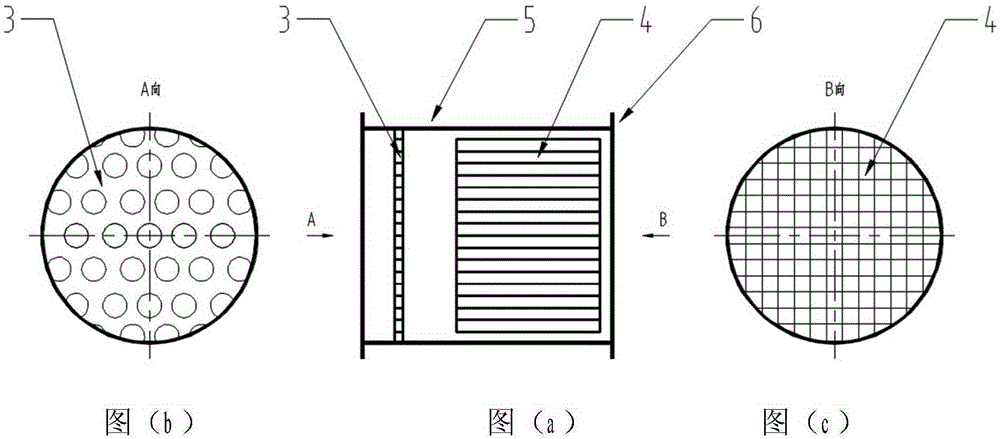

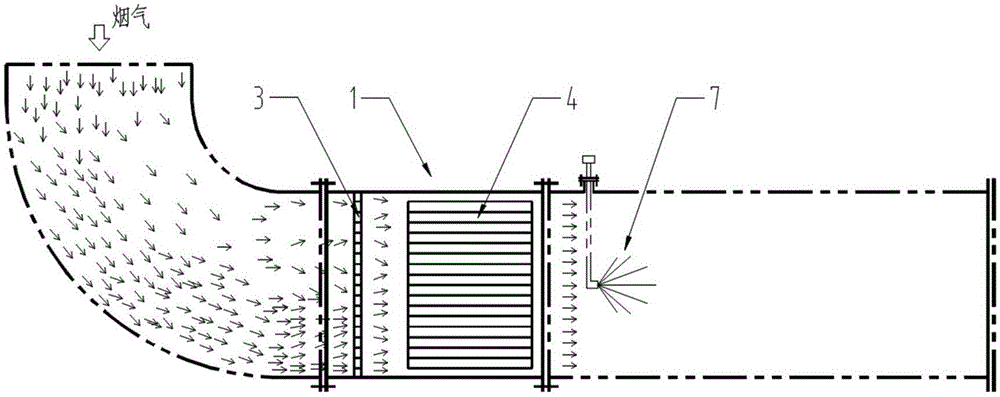

[0015] refer to figure 1 , a selective catalytic reduction (SCR) denitrification airflow uniform distribution device, including a mixer (2) in the SCR denitration device, and the airflow uniform distribution device 1 is connected to the front part of the mixer 2 in the SCR denitration device; refer to figure 2 , the air flow uniform distribution device 1 includes a casing 5, flanges 6 are provided at both ends of the casing 5, and the flanges 6 at both ends are respectively connected to the front flue and the mixer 2 in the rear SCR denitrification device through bolts, nuts and gaskets. Assembled and connected with sheets, etc., the interior of the shell 5 is fixed with the front-stage porous uniform distribution plate 3 and the rear-stage multi-tube uniform distribution device 4 along the axial direction. The pre-stage porous uniform plate 3 is a steel plate with a pluralit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com