Microfluidic chip capable of realizing high-efficiency mixing

A microfluidic chip and fluid technology, applied in mixers, fluid mixers, laboratory containers, etc., can solve the problems of long mixing time, poor mixing quality, uneven mixing, etc., to achieve fully efficient mixing, fast mixing, etc. mixed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

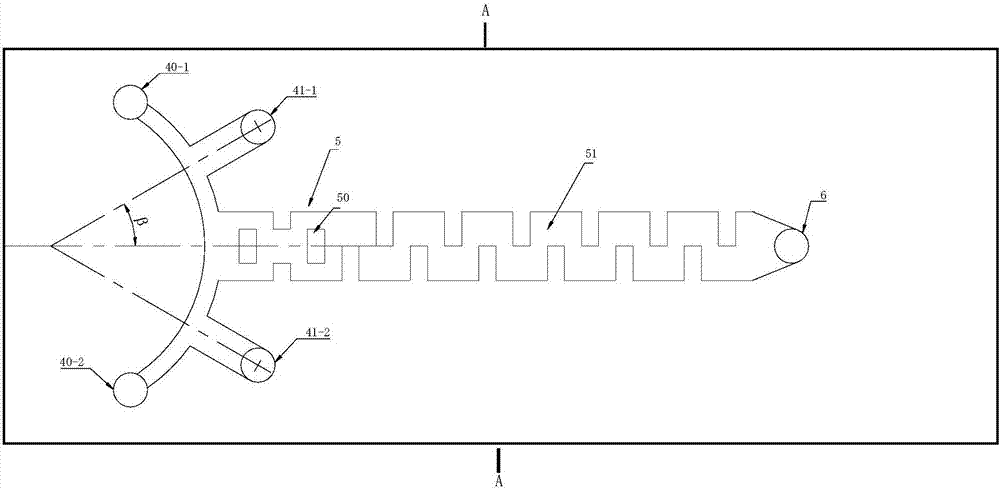

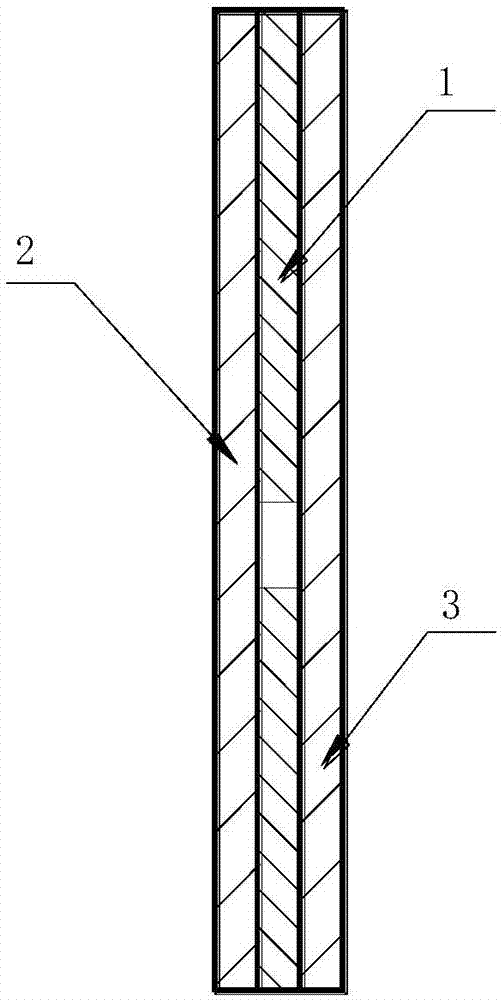

[0025] Such as figure 1 , 2 As shown, a microfluidic chip that can realize efficient mixing includes a substrate 1, an upper glass sheet 2 and a lower glass sheet 3 covering the upper and lower sides of the substrate, the substrate 1 is provided with channels of different geometric structures, and the channels include Inlet channel 4 , straight channel 5 and outlet channel 6 ; said channels are evenly distributed on substrate 1 . The inlet passage 4 is symmetrical about the central axis of the substrate 1, and an arc channel is provided at one end of the substrate 1 as the inlet channels 40-1 and 40-2 of the fluid A; the radially outward extension of the arc channel is provided with The inlet channels 41-1, 41-2 for fluid B, and the channels for fluid A and B form a crown shape. The front section of the straight channel 5 is inlaid with inserts 50 near the entrance channel, and the middle and rear sections of the straight channel 5 are concave-convex channels 51 that are eve...

Embodiment 2

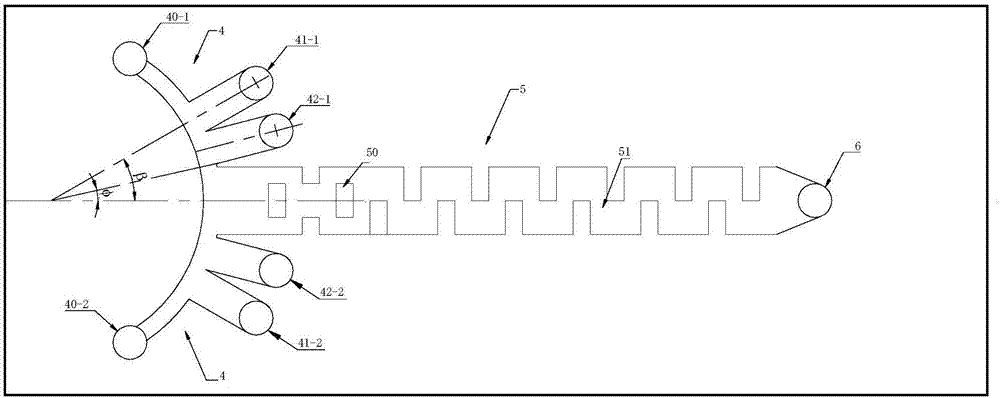

[0027] Such as image 3 As shown, the difference from Embodiment 1 is that the inlet passages 42-1, 42-2 of fluid C are also provided at the radially outward extension of the arc passage, the passages of fluid B and C are next to each other, and the inlet passage of fluid C is connected to the straight passage 5 Adjacent, the fluid A channel forms a crown shape with the fluid B and C channels. The angle β between the central axis of the inlet channel of fluid B and the central axis of the straight channel ranges from 15° to 75°, and the angle φ between the side of the inlet channel of fluid C near the straight channel and the central axis of the straight channel ranges from 10° to 35°. In this embodiment, the runners B and C are next to each other, and the runners B and C can also be connected by an arc channel, and the positions of the two can also be interchanged, and the layout is not limited to this embodiment.

Embodiment 3

[0029] Such as Figure 4 As shown, a microfluidic chip that can realize efficient mixing includes a substrate 1, an upper glass sheet 2 and a lower glass sheet 3 covering the upper and lower sides of the substrate, the substrate 1 is provided with channels of different geometric structures, and the channels include Inlet channel 4 , straight channel 5 and outlet channel 6 ; said channels are evenly distributed on substrate 1 . The inlet channel 4 is located on one side of the substrate, and an arc channel is provided at one end of the substrate 1 as an inlet channel 40-1 of fluid A; an inlet channel of fluid B is provided at the radially outward extension of the arc channel 41-1, the channels of fluid A and B form a half crown shape. The inner side of the circular arc channel, that is, the side with a small radius, is the arc tangent line instead of the arc at the confluence with the straight channel. The front section of the straight channel 5 is inlaid with inserts 50 near...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com