Solution low-temperature extraction device and efficient extraction process thereof

An extraction device and low-temperature technology, which is applied in the field of coffee extraction equipment, can solve problems such as unfavorable mixing and affecting coffee quality, and achieve the effects of ensuring service life, avoiding waste of resources, and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

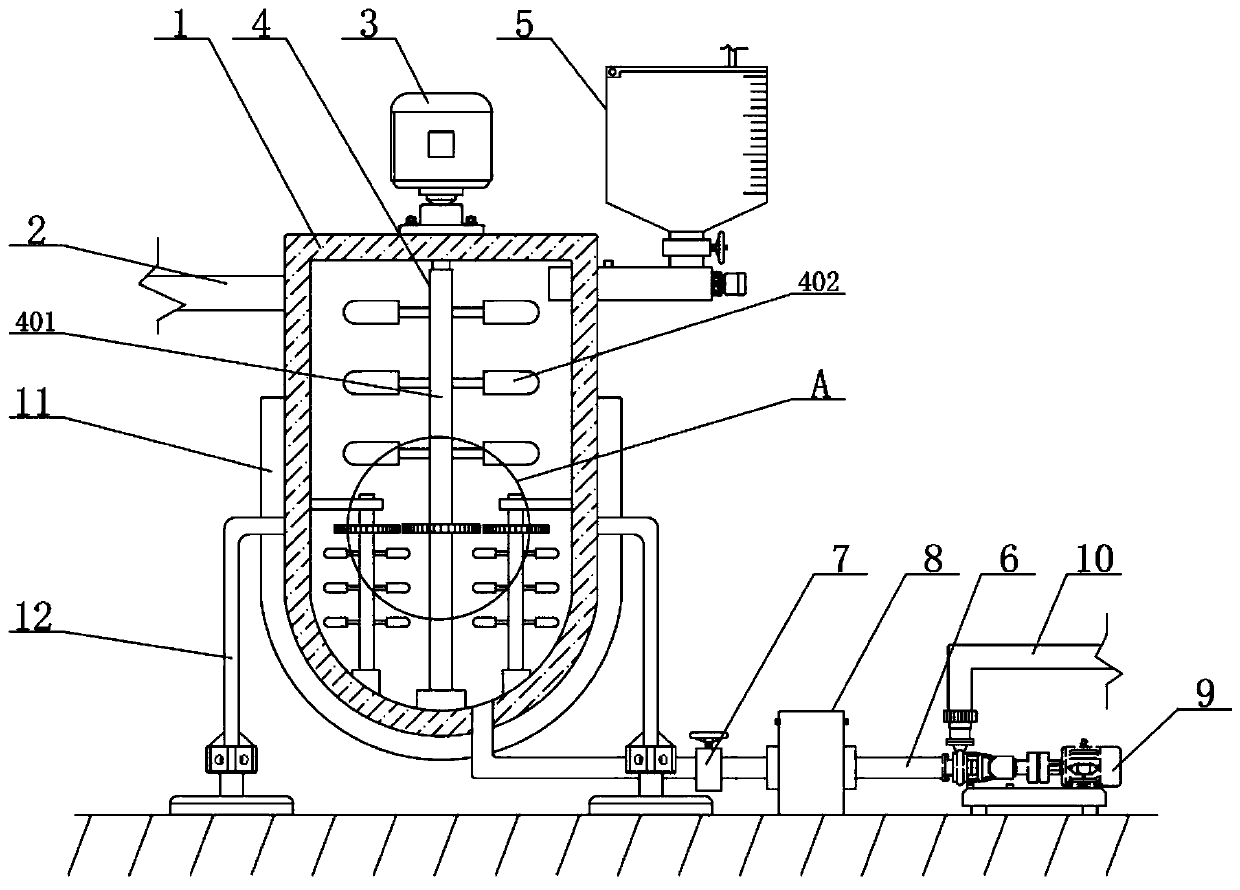

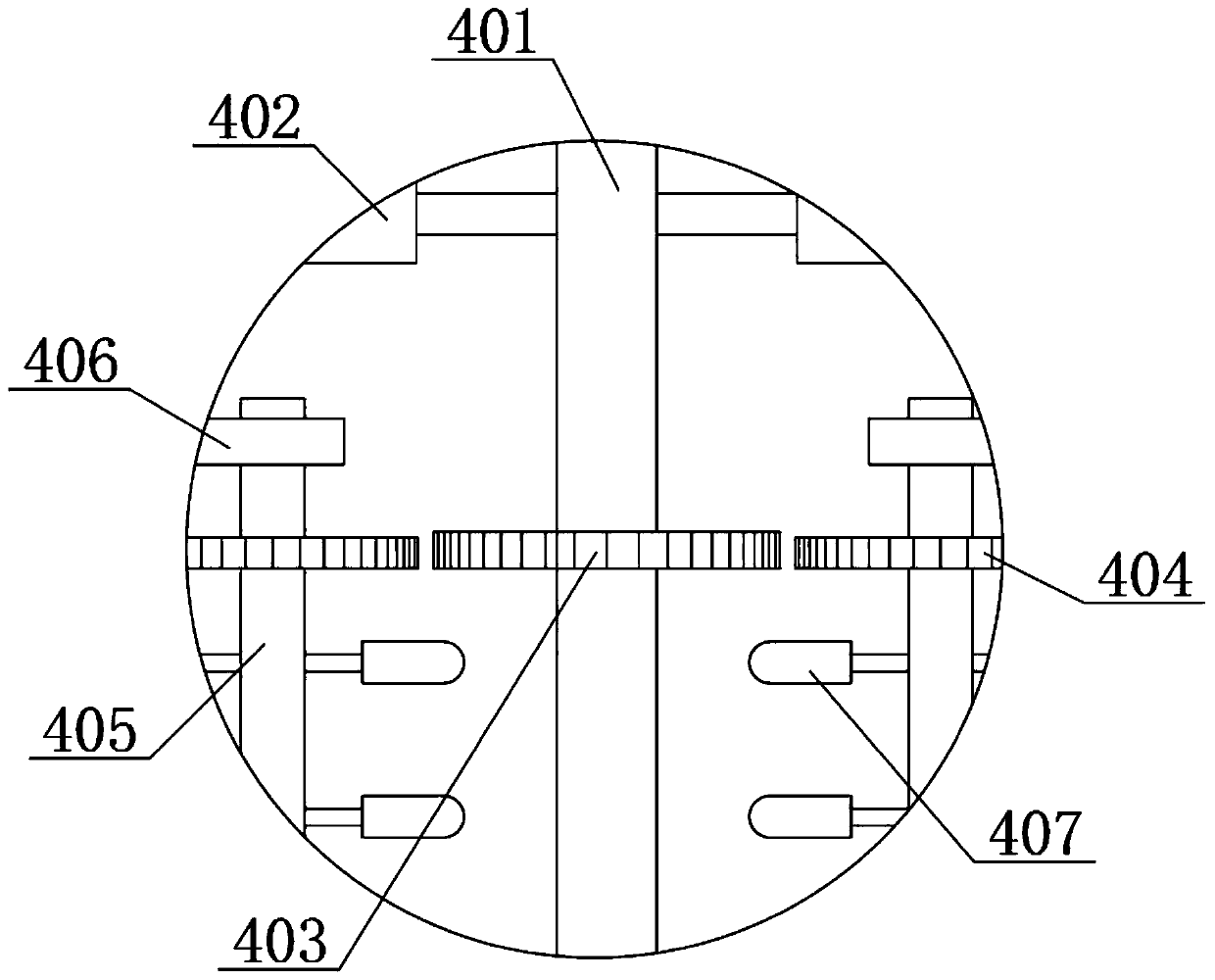

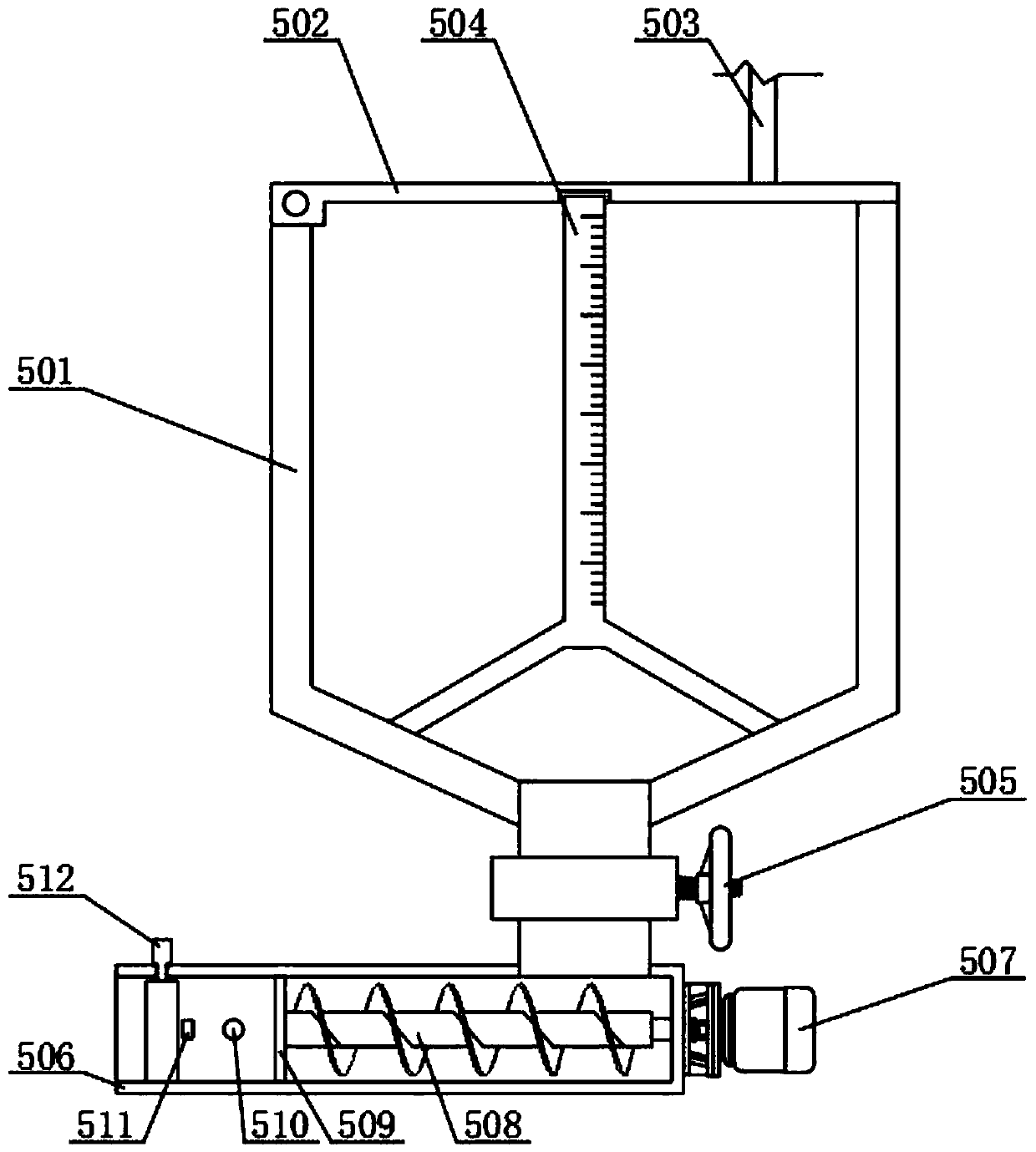

[0029] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , the present invention provides a technical solution:

[0030]A solution low-temperature extraction device and its high-efficiency extraction process, comprising an extraction tank 1 and a water inlet pipe 2, the water inlet pipe 2 is connected above the left end surface of the extraction tank 1, and a stirring motor 3 is fixedly connected to the upper end surface of the extraction tank 1. The right end face of the extraction tank 1 is fixedly connected with an adding device 5, and the adding device 5 includes an adding bucket 501 and a rotating cover 502, and the upper end surface of the adding bucket 501 is connected with a rotating cover 502 rotating on the left side, and the upper end surface of the rotating cover 502 is The air inlet pipe 503 is connected, the first valve 505 is fixedly connected to the outside of the bottom of the adding bucket 501, and the metering rod 504 is fixedly connected to ...

Embodiment 2

[0038] In Embodiment 2, the same parts as Embodiment 1 will not be repeated. The difference is that when the water outlet speed of the connecting pipe 10 slows down, it means that the first filter cover 807 is blocked by impurities. At this time, it is necessary to rotate the limit screw 805 , and then pull the handle 804 upwards to drive the sealing plate 803 to move upwards, and the sealing plate 803 drives the stop ring 806, the first filter cover 807 and the second filter cover 808 to move upwards, and then the surface of the first filter cover 807 and the second filter cover can be The inner side of the cover 808 is cleaned to ensure its filtering effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com