Automatic feeding and discharging stirrer for building

An automatic material feeding and construction technology, which is applied in the direction of cement mixing device, unloading device, and selling raw material supply device, etc., can solve the problems of reducing construction efficiency and cumbersome feeding, and achieve the effect of high efficiency and sufficient mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

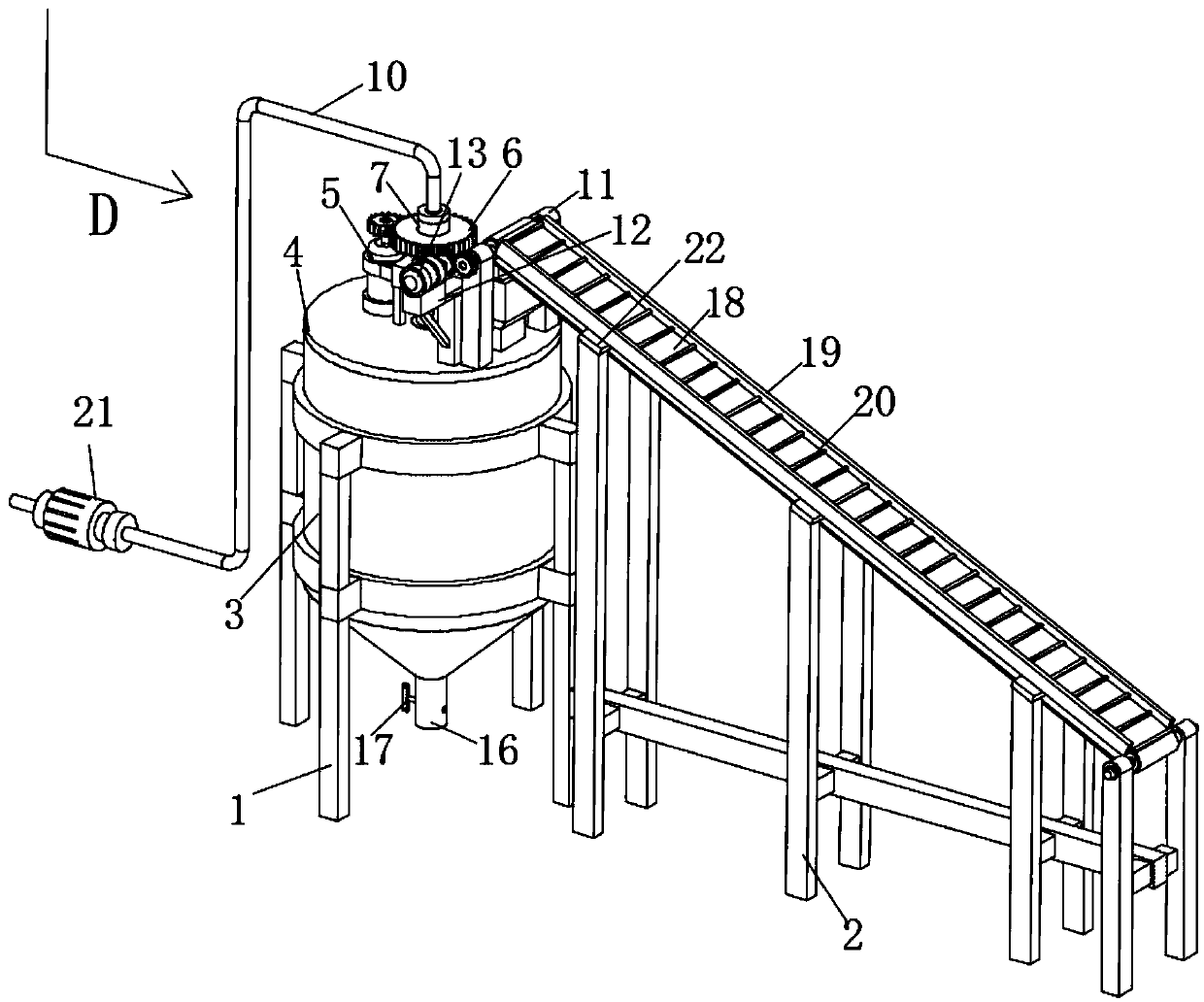

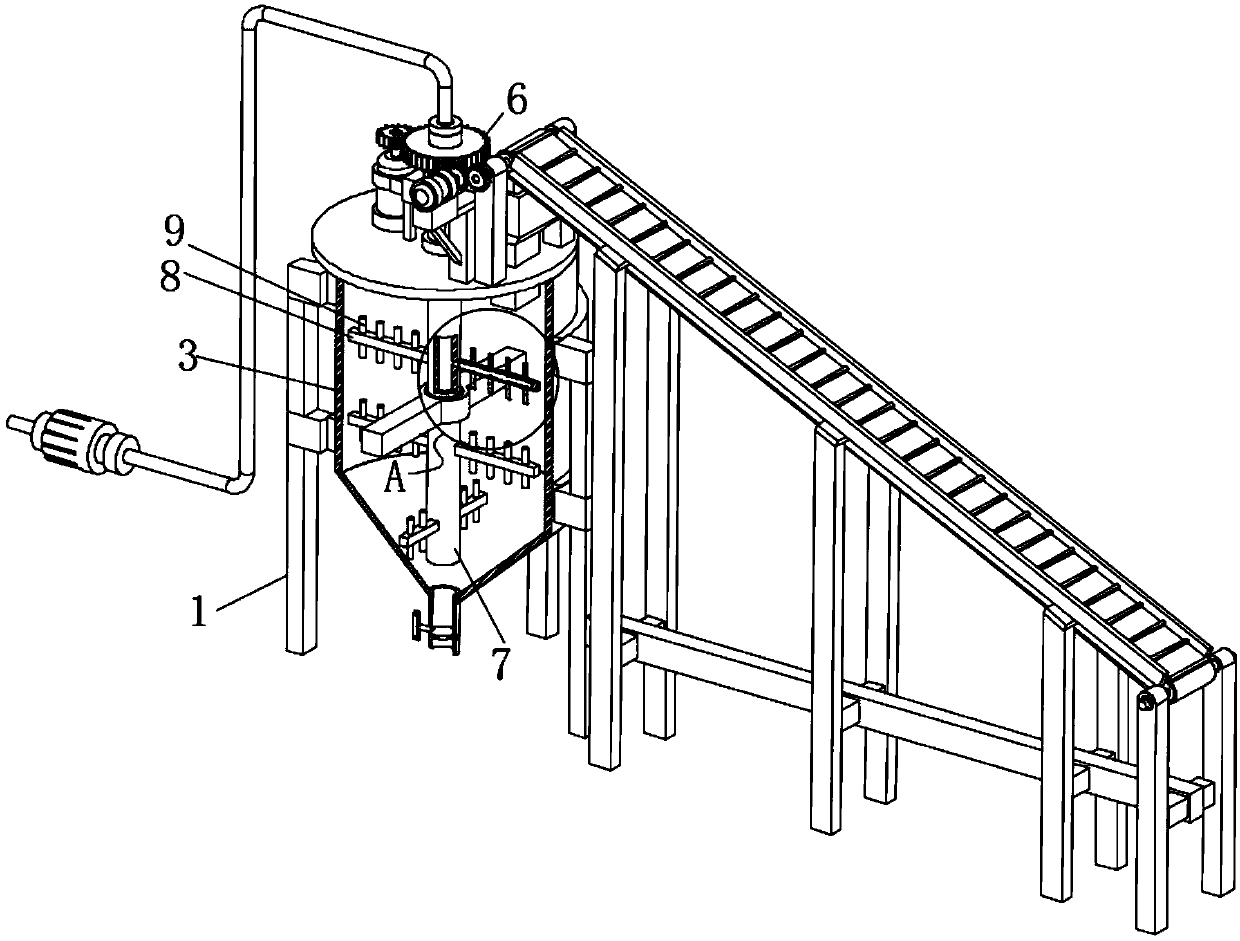

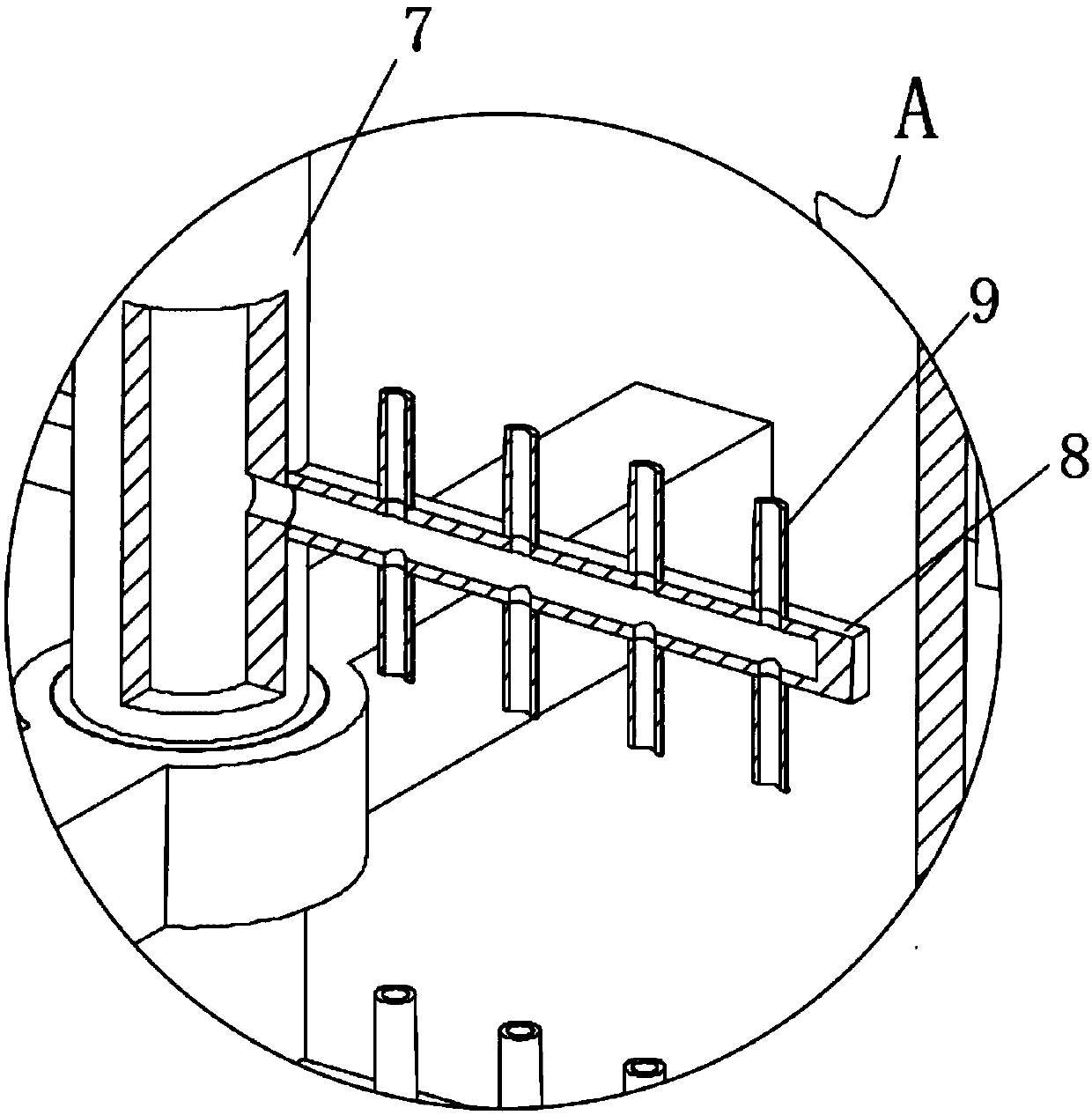

[0029] Embodiment 2: A mixer for automatic feeding and discharging for construction, including a stirring tank support 1 and a transmission mechanism support 2, a stirring tank 3 is fixedly supported above the stirring tank support 1, and the top of the mixing tank 3 is sealed with a tank cover 4. The upper surface of the tank cover 4 is fixedly welded with a stirring motor 5, and the upper end of the output shaft of the stirring motor 5 is fixedly welded with a stirring drive gear, and the inner side of the stirring drive gear is meshed with a stirring shaft gear 6, and the middle part of the stirring shaft gear 6 is fixedly interspersed There is a hollow stirring shaft 7, and the lower end of the hollow stirring shaft 7 penetrates into the inside of the stirring tank 3, the surface of the hollow stirring shaft 7 is fixedly provided with a plurality of stirring rods 8, and the upper and lower surfaces of the stirring rods 8 are fixedly connected with a plurality of stirring sup...

Embodiment 3

[0031]Embodiment 3: A mixer for automatic feeding and discharging for construction, including a stirring tank support 1 and a transmission mechanism support 2, a stirring tank 3 is fixedly supported above the stirring tank support 1, and the upper sealing cover of the mixing tank 3 is closed with a tank cover 4. The upper surface of the tank cover 4 is fixedly welded with a stirring motor 5, and the upper end of the output shaft of the stirring motor 5 is fixedly welded with a stirring drive gear, and the inner side of the stirring drive gear is meshed with a stirring shaft gear 6, and the middle part of the stirring shaft gear 6 is fixedly interspersed There is a hollow stirring shaft 7, and the lower end of the hollow stirring shaft 7 penetrates into the inside of the stirring tank 3, the surface of the hollow stirring shaft 7 is fixedly provided with a plurality of stirring rods 8, and the upper and lower surfaces of the stirring rods 8 are fixedly connected with a plurality ...

Embodiment 4

[0035] The difference from Embodiment 1 is that: the stirring tank support 1 is provided with a plurality of supporting legs, and there are two groups of four supporting legs.

[0036] Further, in the above solution, the two sets of supporting legs are center-symmetrical with respect to the vertical central axis of the stirring tank 3 , and the supporting legs can play a good stabilizing effect on the stirring tank 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com