An operating table for cutting hardware pipe fittings

A technology for consoles and pipe fittings, which is applied to workbenches, manufacturing tools, etc., can solve the problems of metal pipe fittings deviation, reduced processing quality, and insufficient clamping force, so as to improve stability, improve clamping effect, and not easily slip Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

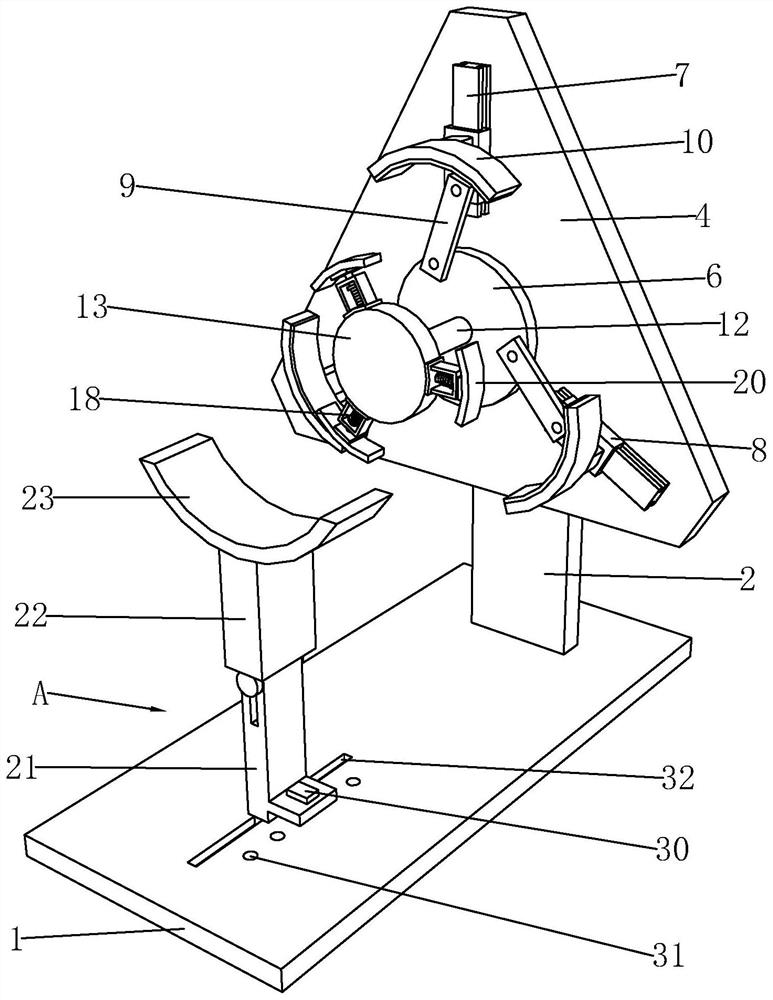

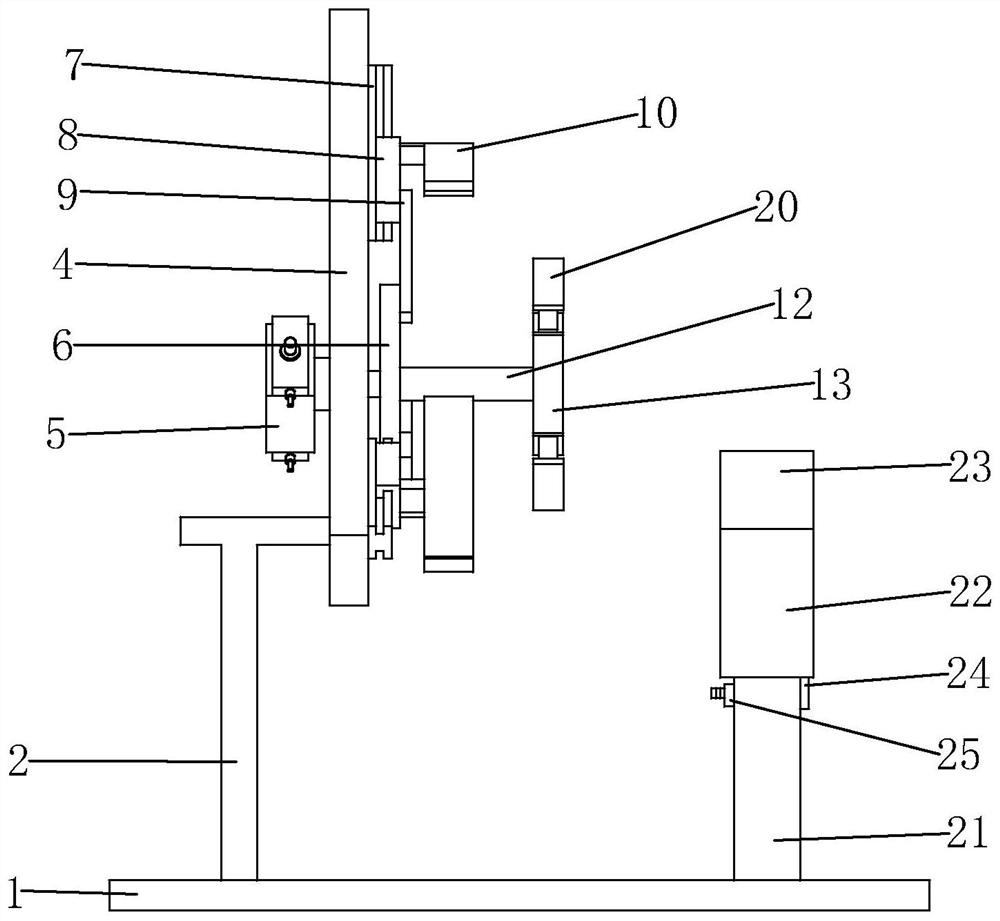

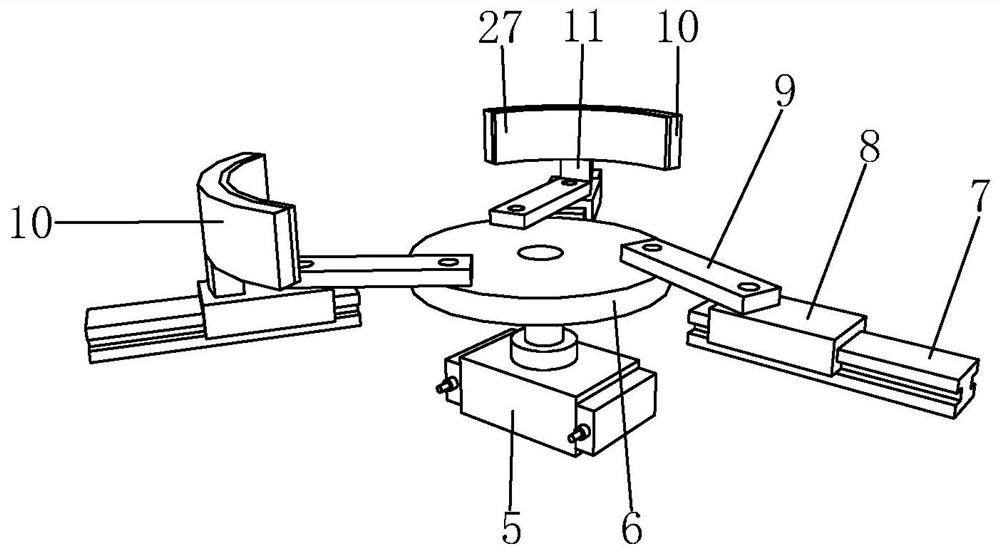

[0024] like Figure 1 to Figure 5 As shown, it is an operation platform for cutting metal pipe fittings according to the present invention, which includes a support platform 1, a support 2 and a lifting frame 3 are respectively provided on the support platform 1, a mounting plate 4 is provided on the support 2, and a mounting plate 4 is provided on the mounting plate 4 respectively. The rotating cylinder 5, the turntable 6 and the fixed guide rail 7, the rotating cylinder 5 is connected with the turntable 6, the fixed guide rail 7 is distributed around the turntable 6, the fixed guide rail 7 is slidably connected with a guide block 8, and the guide block 8 and the turntable 6 are connected with The transmission rod 9 is connected to the eccentric position of the turntable 6, and the fixed guide rail 7 is provided with an arc-shaped splint 10. When the hardware pipe is clamped, the rotating cylinder 5 drives the turntable 6 to rotate, and the turntable 6 drives the guide through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com