Full-automatic dried bean curd production system and dried bean curd production method

A production system and fully automatic technology, applied in cheese substitutes, dairy products, applications, etc., can solve problems such as increased production costs, increased inspection workload, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

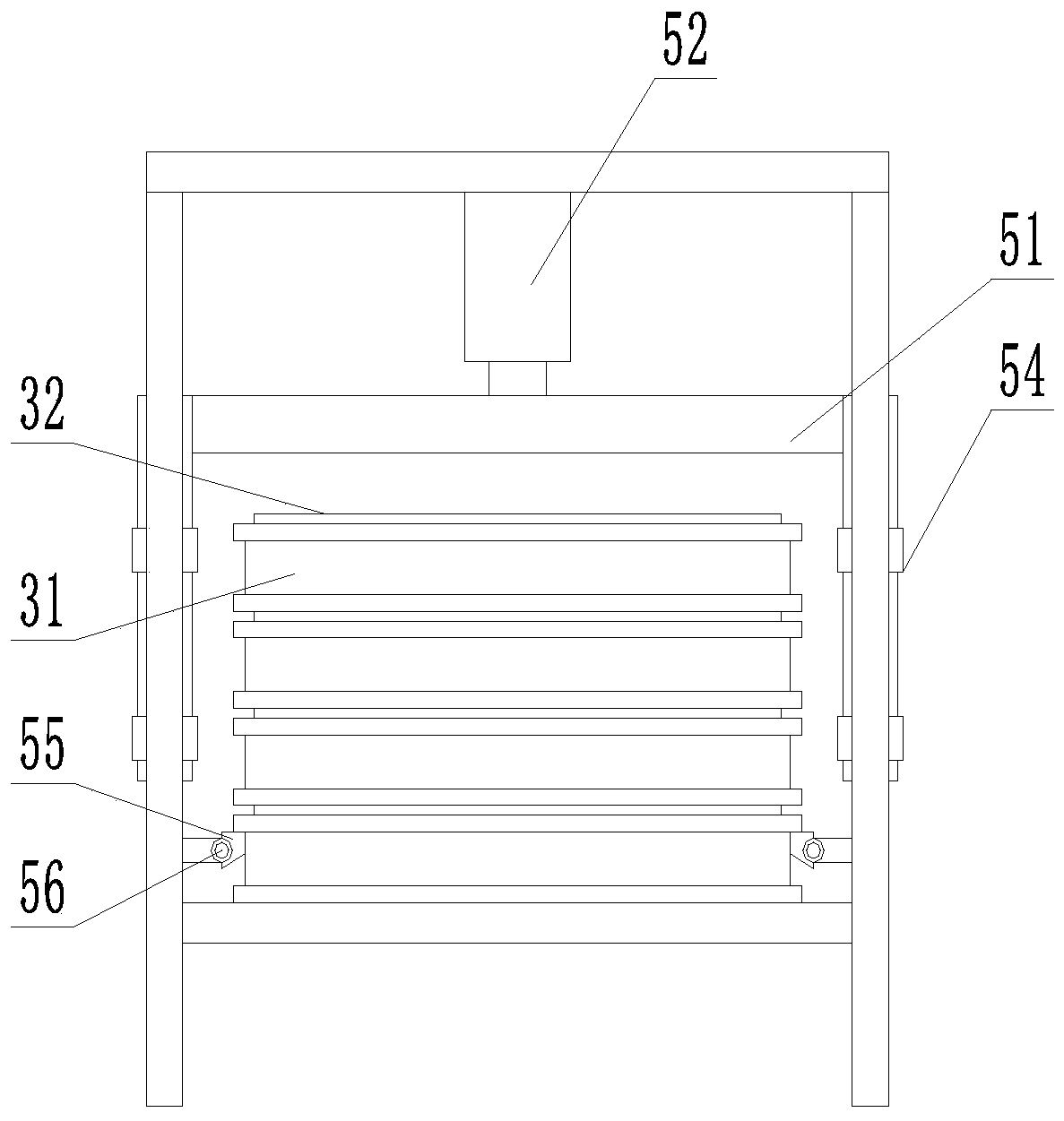

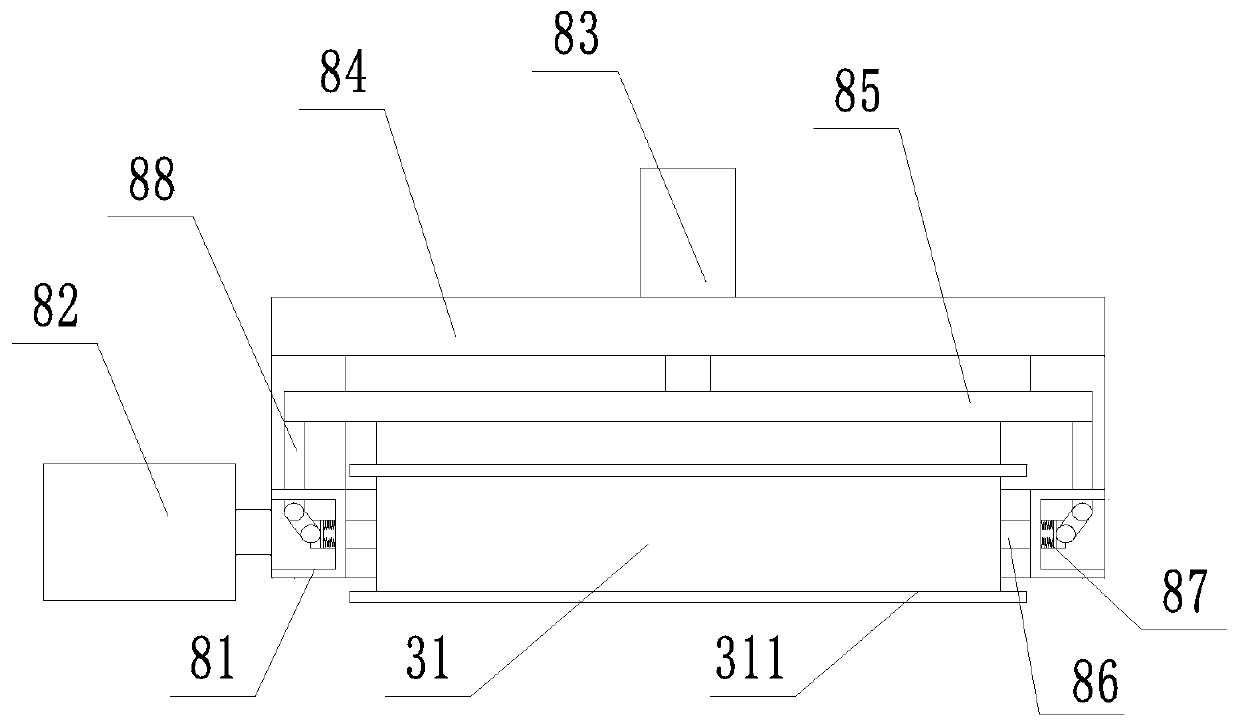

[0032] Such as figure 1 with Figure 5 As shown, a fully automatic dried tofu production system includes a brine making barrel 10, a frame conveying mechanism 30, a cover plate conveying mechanism 40 and a stacking mechanism 50. The bottom of the brine making barrel 10 is provided with an opening, and the opening is provided with a valve. The frame conveying mechanism 30 is arranged on the bottom of the brine pointing bucket 10, and the frame conveying mechanism 30 includes the first conveyor belt and the frame mold 31, the peripheral surface of the frame mold 31 is provided with a limit plate 311, and the cover plate conveying mechanism 40 is provided with At the afterbody of the first conveyor belt, the cover conveying mechanism 40 comprises a second conveyor belt and a frame cover 32, the frame cover 32 is matched with the frame mold 31, and both the frame cover 32 and the frame mold 31 are Several through holes are provided to drain the bean brains. The stacking mechanism...

Embodiment 2

[0036] Such as Figure 2 to Figure 5 As shown, the difference from Embodiment 1 is that it also includes a squeezing mechanism 60 , a splitting mechanism 70 , a flipping mechanism 80 and a cutting mechanism 90 arranged at the tail of the stacking mechanism 50 in sequence.

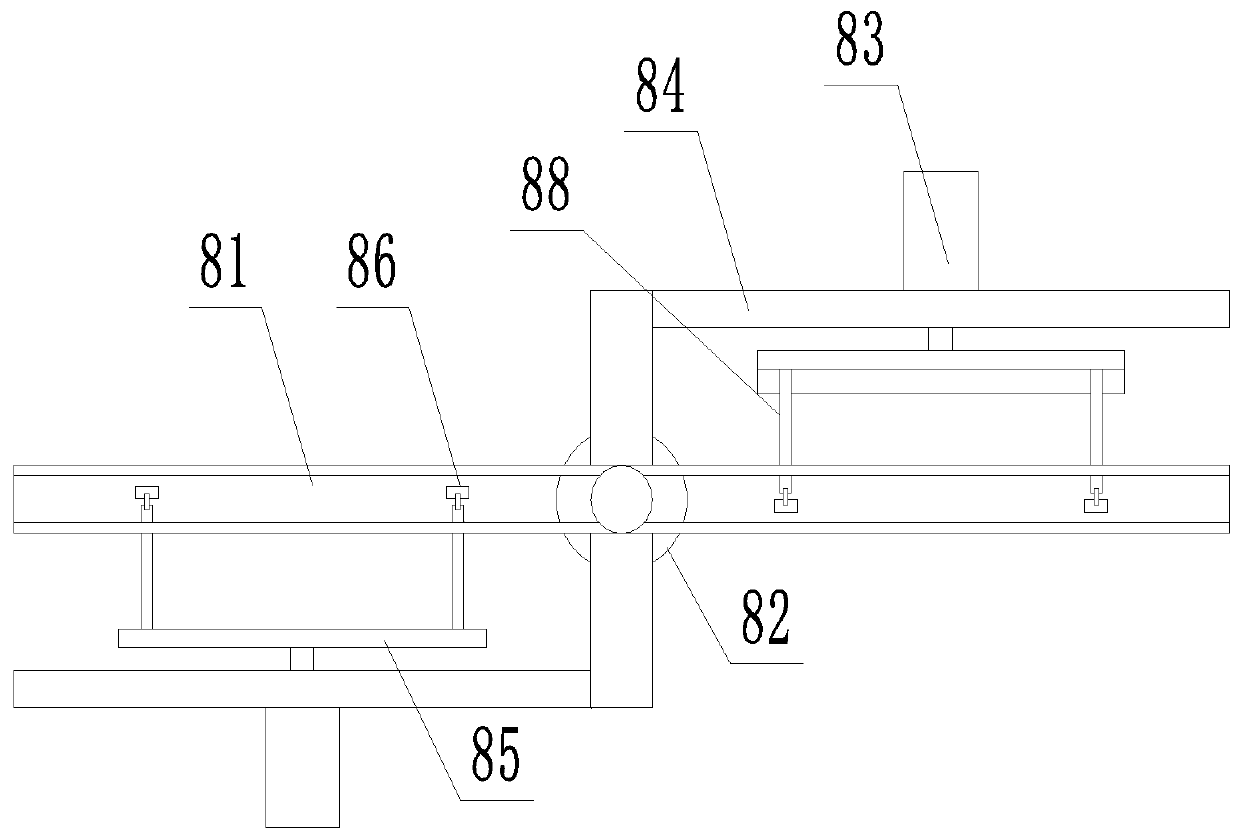

[0037] In a further preferred solution in this embodiment, the turnover mechanism 80 includes a fixed frame 81, a turnover driver 82 (air cylinder) and a platen structure, the turnover driver 82 is fixedly installed at the tail of the split mechanism 70, and the turnover driver The output shaft of 82 is fixedly connected with fixed frame 81, and the pressing plate structure is arranged on the fixed frame 81, and the pressing plate structure is used for clamping type frame mold 31 and compresses the bean curd block in type frame mold 31 simultaneously. Utilize the turning plate driving part 82 to realize the 180° turnover of the pressing plate structure of the pressing frame mold 31 and the internal bean bra...

Embodiment 3

[0043] A dried tofu production method of a fully automatic dried tofu production system, comprising a marinade barrel 10, a frame conveying mechanism 30, a cover plate conveying mechanism 40, a stacking mechanism 50, a pressing mechanism 60, a splitting mechanism 70, a plate turning mechanism 80 and Cutting mechanism 90, comprises the following steps:

[0044] S1. First, import soymilk into the stewed barrel 10, open the valve at the opening, and discharge the internal bean brain into the frame mold 31, and then transport it to the next step through the conveyor belt to carry out the frame cover plate 32 and the frame. The matching of the mold 31 realizes the preliminary shaping of the bean brain;

[0045] S2. By extending the output end of the stacking driver 52, the guide 54 is moved down along the fixed frame 51. During the downward movement, when the stacking part 55 touches the limit plate 311, it will rotate and then under the action of the torsion spring Realize reset ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com