Cutting equipment for automobile shock absorber spring

A technology of automobile shock absorber and cutting equipment, applied in the field of automobile shock absorber, can solve the problems of uneven cutting surface and deformation, and achieve the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

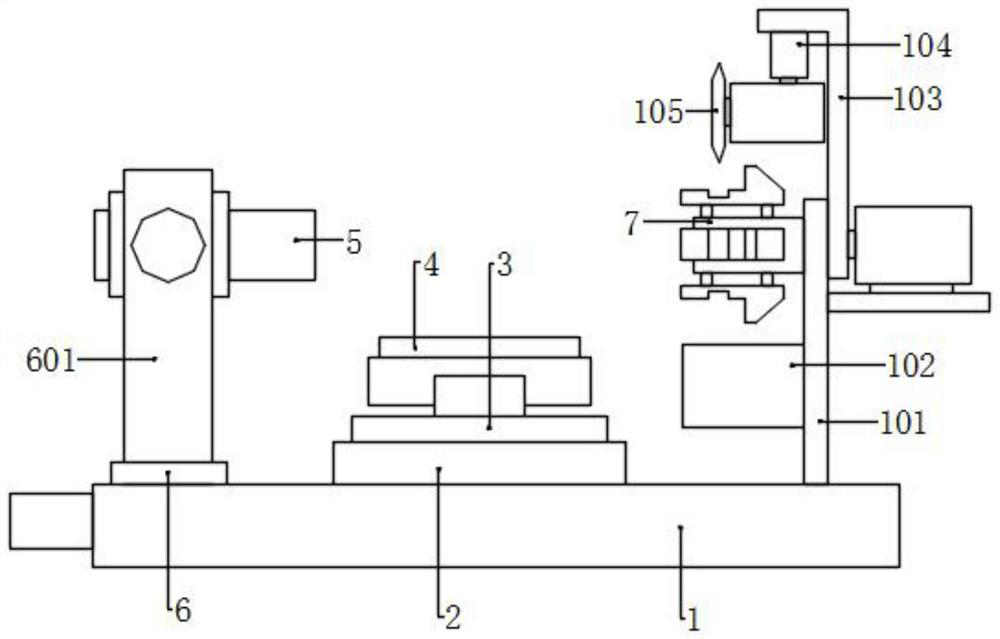

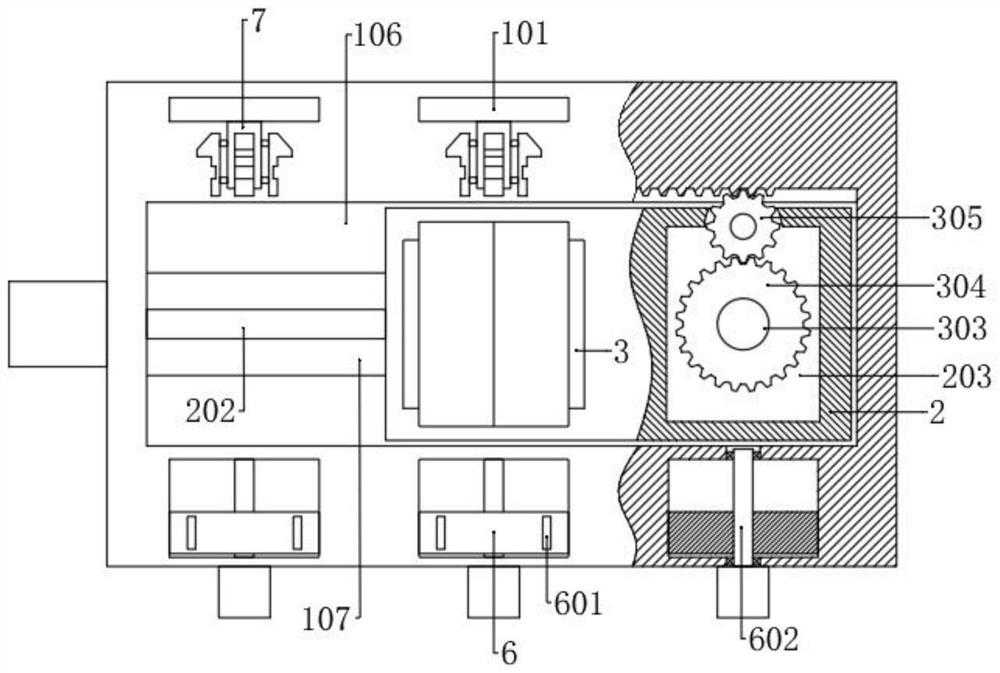

[0043] Please refer to accompanying drawing, the present invention provides a kind of technical scheme: a kind of cutting equipment that is used for automobile shock absorber spring, comprises workbench 1, and the top surface of workbench 1 is provided with first moving groove 106, and first moving groove 106 The middle slide is connected with a moving seat 2, the bottom of the moving seat 2 is connected with a first moving assembly, the top surface of the moving seat 2 is symmetrically provided with two rotating seats 3, and the rotating seat 3 is provided with a placement assembly;

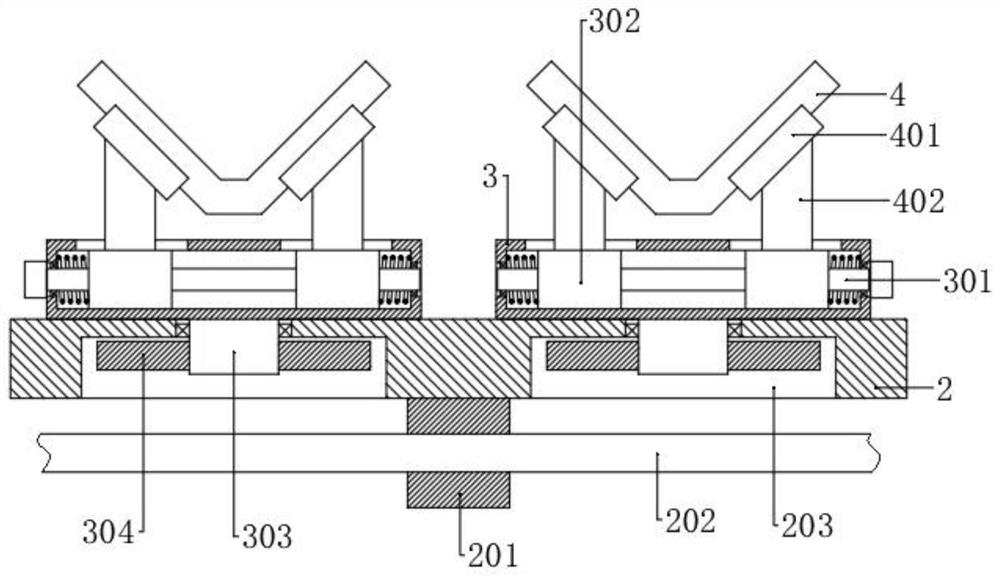

[0044] The center of the bottom surface of the rotating seat 3 is fixed with a rotating shaft 303, and the bottom of the moving seat 2 is correspondingly provided with two rotating grooves 203. The rotating shaft 303 is connected to the top of the rotating groove 203 in rotation, and the bottom end is fixed with a first gear 304. One side of a gear 304 is meshed with a second gear 305, and the si...

Embodiment 2

[0050] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that the placement assembly includes two support columns 401 symmetrically arranged on the top surface of the rotating seat 3, and the top surfaces of the two support columns 401 are connected with a V-shaped placement Seat 4, the two top surfaces of placing seat 4 are respectively provided with T-shaped spring grooves, and the spring block 405 of corresponding shape is slidably connected in the spring groove, and the two ends of spring block 405 and the two ends of spring groove respectively A spring is connected, and the outer ends of the two spring blocks 405 are jointly fixed with a V-shaped spring plate 404 .

[0051] When the shock absorber spring is placed on the spring plate 404 on the placement seat 4, the positioning assembly 5 pushes the shock absorber spring, so that the spring plate 404 moves relative to the placement seat 4, so that the other end of the shock a...

Embodiment 3

[0057] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that the rotating assembly includes a rotating box 501 located between the upper parts of the two side plates 601, and connecting cylinders are symmetrically fixed on the two side walls of the rotating box 501, and in the connecting cylinder A fixed cylinder 603 is rotatably connected, and the two ends of the fixed cylinder 603 extend into the inside of the rotating box 501, and are jointly connected with a fixed shell 604, and the fixed shell 604 is provided with a third moving assembly, and the outer end of the fixed cylinder 603 extends out to rotate box 501, and is fixedly connected with the corresponding side plate 601, a first ring gear 502 is fixed on one of the connecting cylinders, the bottom of the first ring gear 502 is engaged with a rotating gear 507, and the rotating gear 507 is connected with a motor, when it is necessary to use When the positioning assembly 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com