A kind of mold blank cutting equipment and cutting method thereof

A technology of cutting equipment and blanks, which is applied in the direction of separation methods, chemical instruments and methods, and the use of liquid separation agents, etc., can solve the problems of poor environment in the cutting workshop, increased labor, and inability to deal with smoke and particles, so as to avoid overheating and improve cutting efficiency. Effect, the effect of avoiding the spread of harmful smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

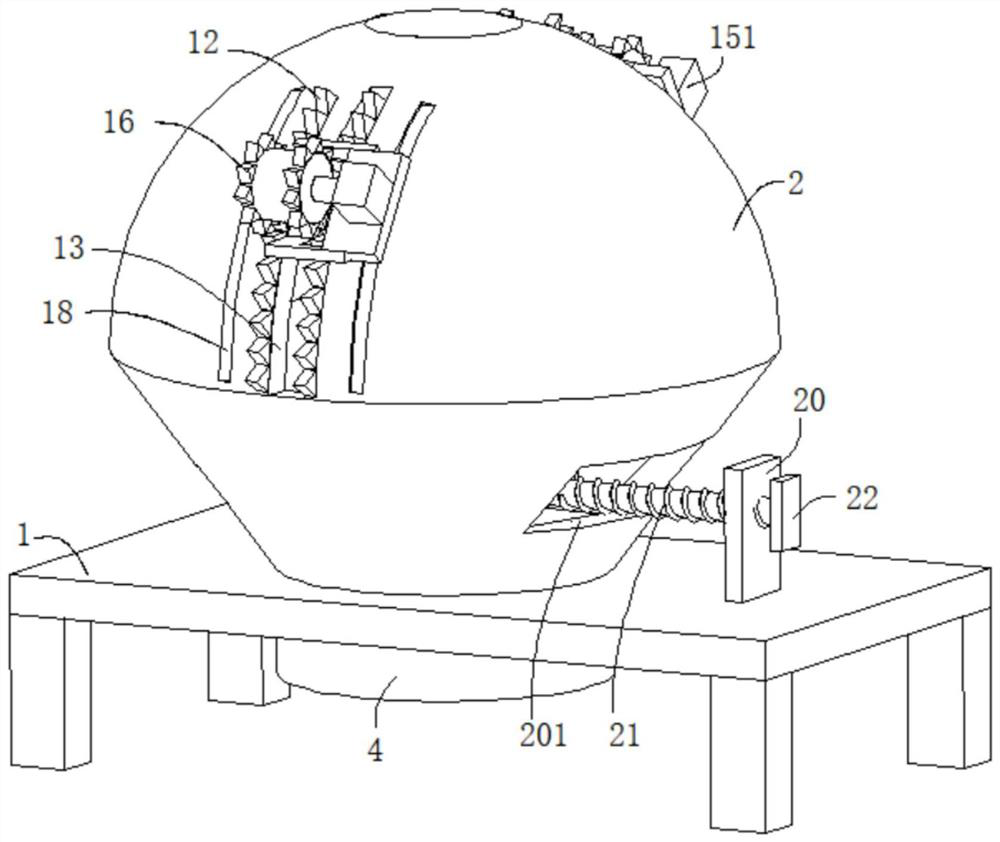

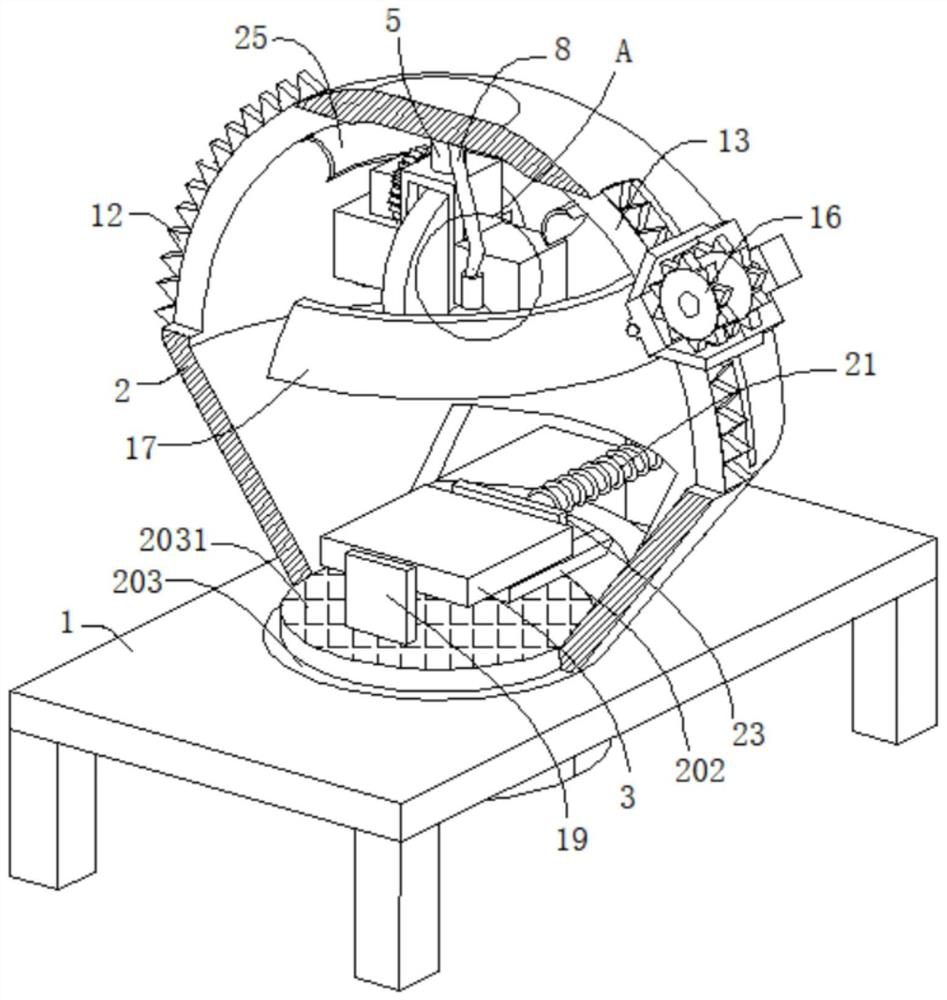

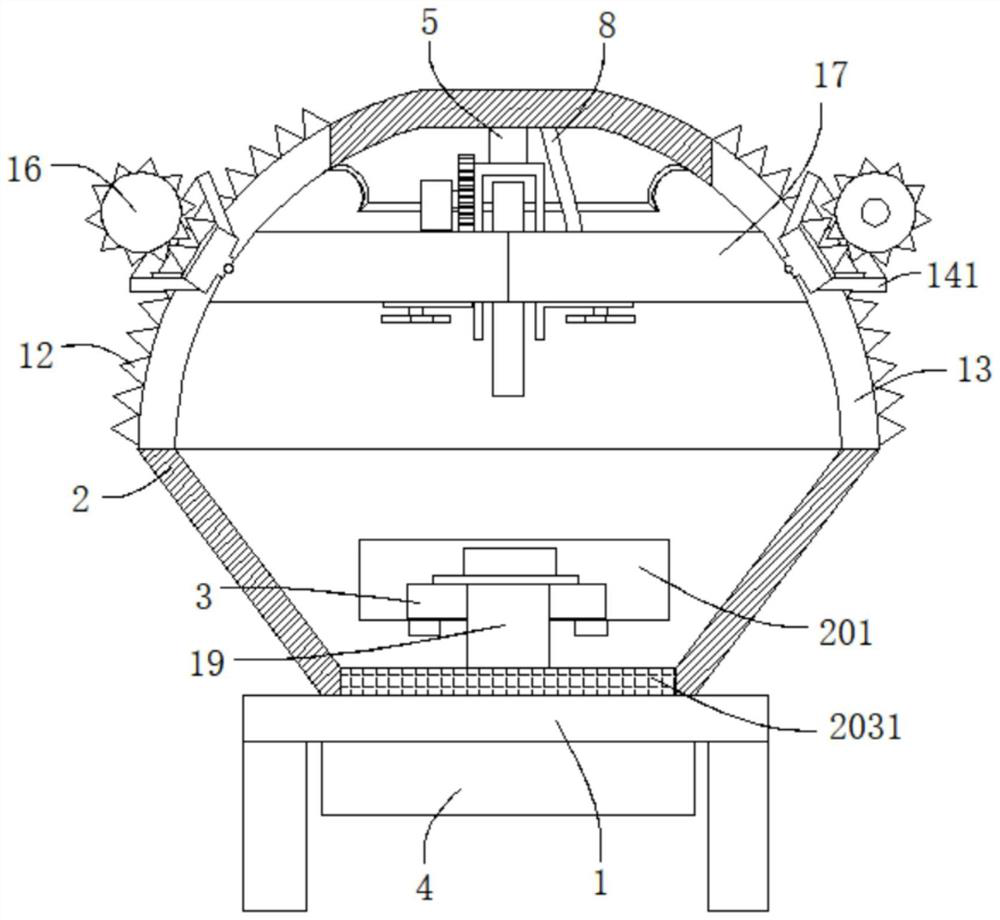

[0039] refer to figure 1 , figure 2 , Figure 5 and Figure 7 , a mold blank cutting equipment and cutting method thereof, comprising a frame 1, the top of the frame 1 is connected with a shell 2, the outer wall of the shell 2 is dug with an outlet 201, the inner wall of the shell 2 is connected with a fixed plate 202, and the fixed plate 202 The top of the frame 1 is movably connected with a workpiece 3, the bottom of the housing 2 is dug with a through hole 203, the inner wall of the through hole 203 is connected with a filter screen 2031, the bottom wall of the frame 1 is connected with a water storage tank 4, and the water storage tank 4 and the through hole 203 Interconnected, the top of the housing 2 is connected with the fixed shaft 5, the bottom of the fixed shaft 5 is connected with the fixed frame 501, the fixed frame 501 is connected with the first rotating shaft 502 for rotation, the outer wall of the first rotating shaft 502 is connected with the cutting tool 5...

Embodiment 2

[0042] refer to figure 1 , figure 2 , image 3 , Figure 4 and Image 6 , a mold blank cutting device and its cutting method are basically the same as in Embodiment 1, and furthermore, the outer walls on both sides of the housing 2 are connected with a rack group 12, and the rack group 12 includes two racks, and the housing 2 The outer wall is dug with a concave hole 13, the concave hole 13 is placed between two racks, the inner wall of the concave hole 13 is movably connected with a moving block 14, the bottom wall of the moving block 14 is connected with a scraper 17 through a hinge, and the two scrapers 17 It is offset against the inner wall of the housing 2, and the two scrapers 17 are fixedly connected. Both sides of the outer wall of the moving block 14 are connected with connecting plates 141. The ends of the two connecting plates 141 away from the moving block 14 are connected with a placement plate 15. The placement plate 15 The outer wall is connected with a sec...

Embodiment 3

[0045] refer to figure 2 and Figure 8 , a mold blank cutting device and its cutting method are basically the same as in Embodiment 1, furthermore, the outer wall of the filter screen 2031 is connected with a first splint 19, and the outer wall of the first splint 19 is connected with a telescopic rod 191, and the telescopic rod 191 is far away from One end of the first splint 19 is connected with a force plate 192, the outer wall of the telescopic rod 191 is sleeved with a first elastic element 193, the first elastic element 193 is placed between the first splint 19 and the force plate 192, and the outer wall of the frame 1 is connected There is a positioning plate 20, the internal thread of the positioning plate 20 is connected with a screw rod 21, the outer wall of the screw rod 21 is connected with a handle 22, and the end of the screw rod 21 away from the handle 22 is connected with a second splint 23, the second splint 23 is moved against the workpiece 3, and the force ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com