Lifting platform suitable for supporting feeding of large-pipe-diameter pipes

A technology of lifting platform and large pipe diameter, which is applied in the direction of lifting frame, support, lifting device, etc., can solve the problems of inability to meet the accuracy of pipe feeding, inability to adjust the upper and lower heights of pipes, and low production efficiency, so as to improve production efficiency , to achieve the effect of convenience and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

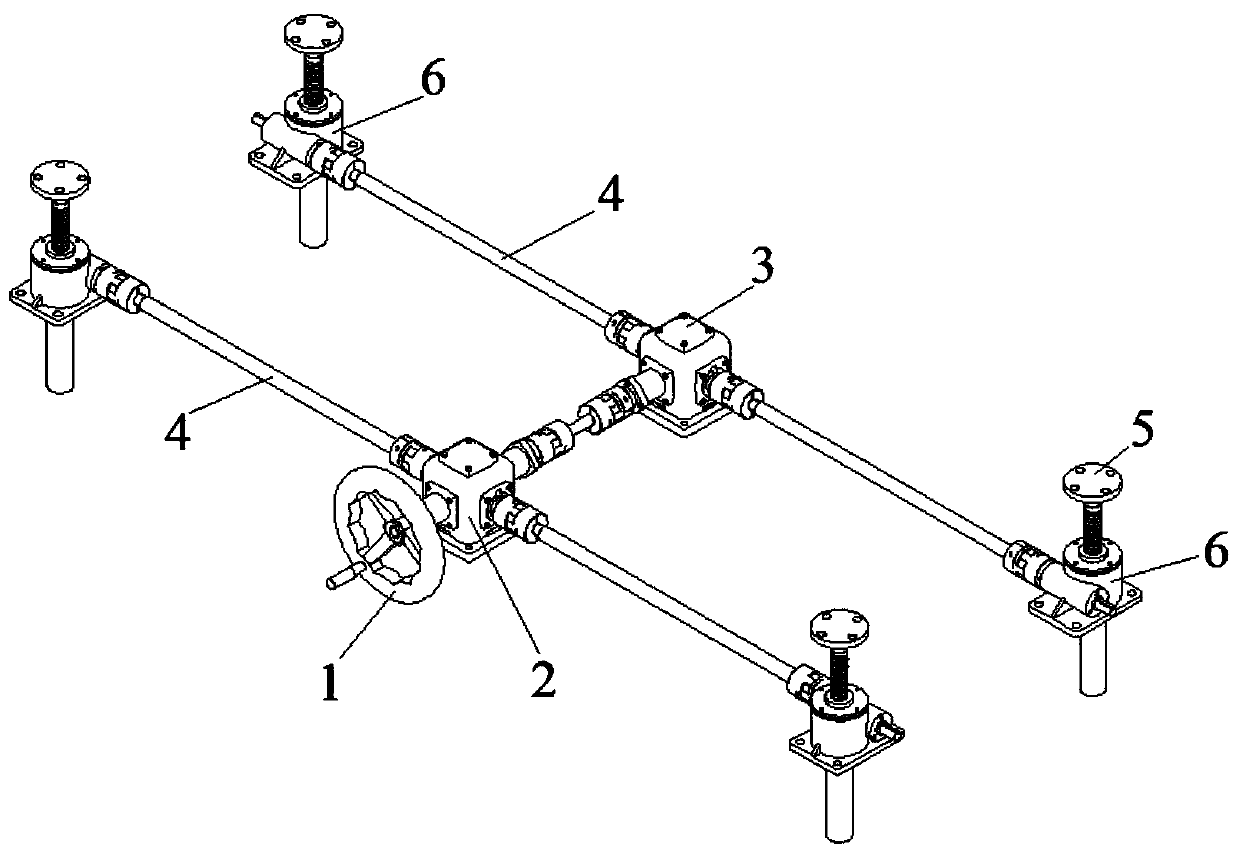

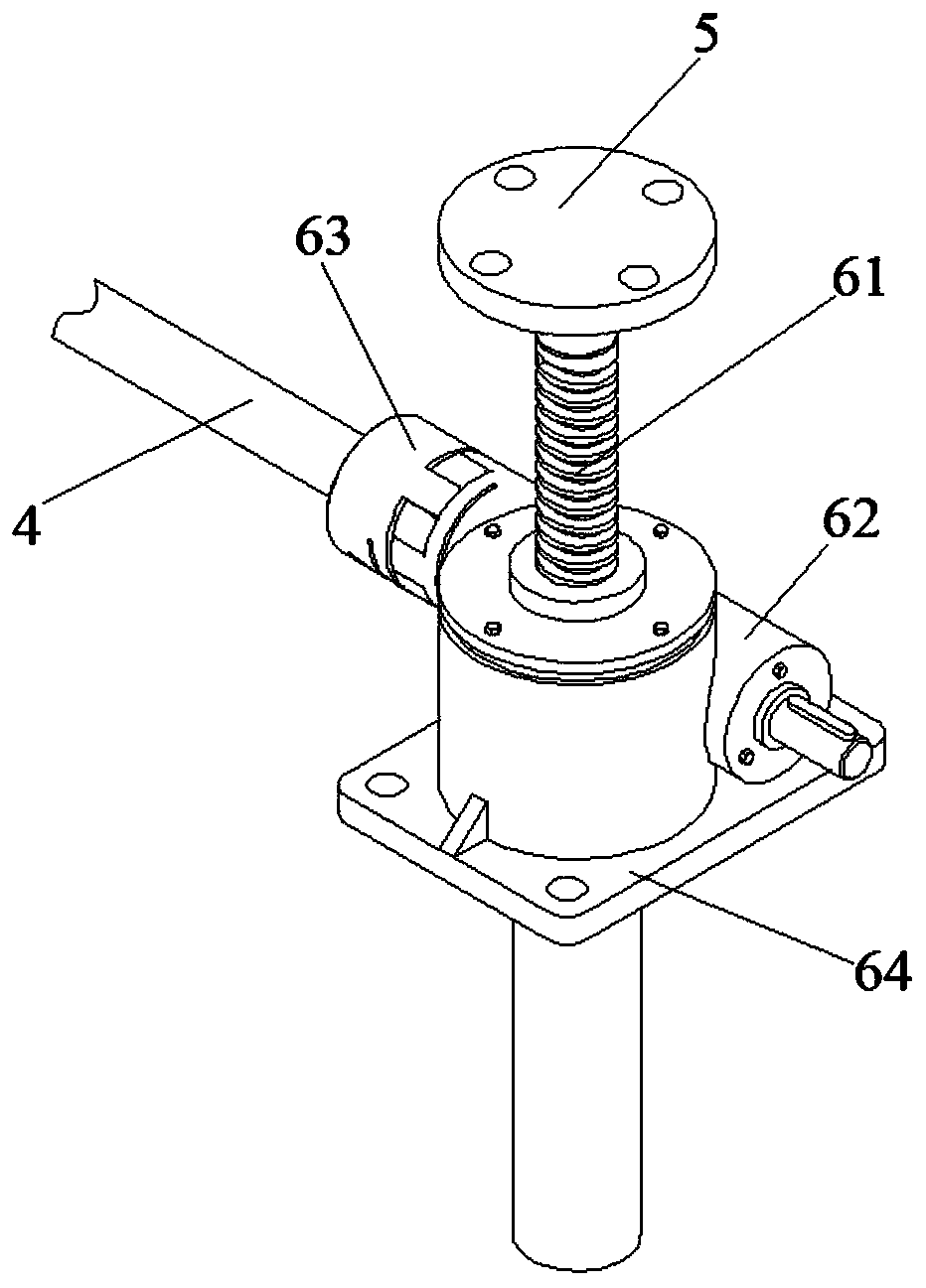

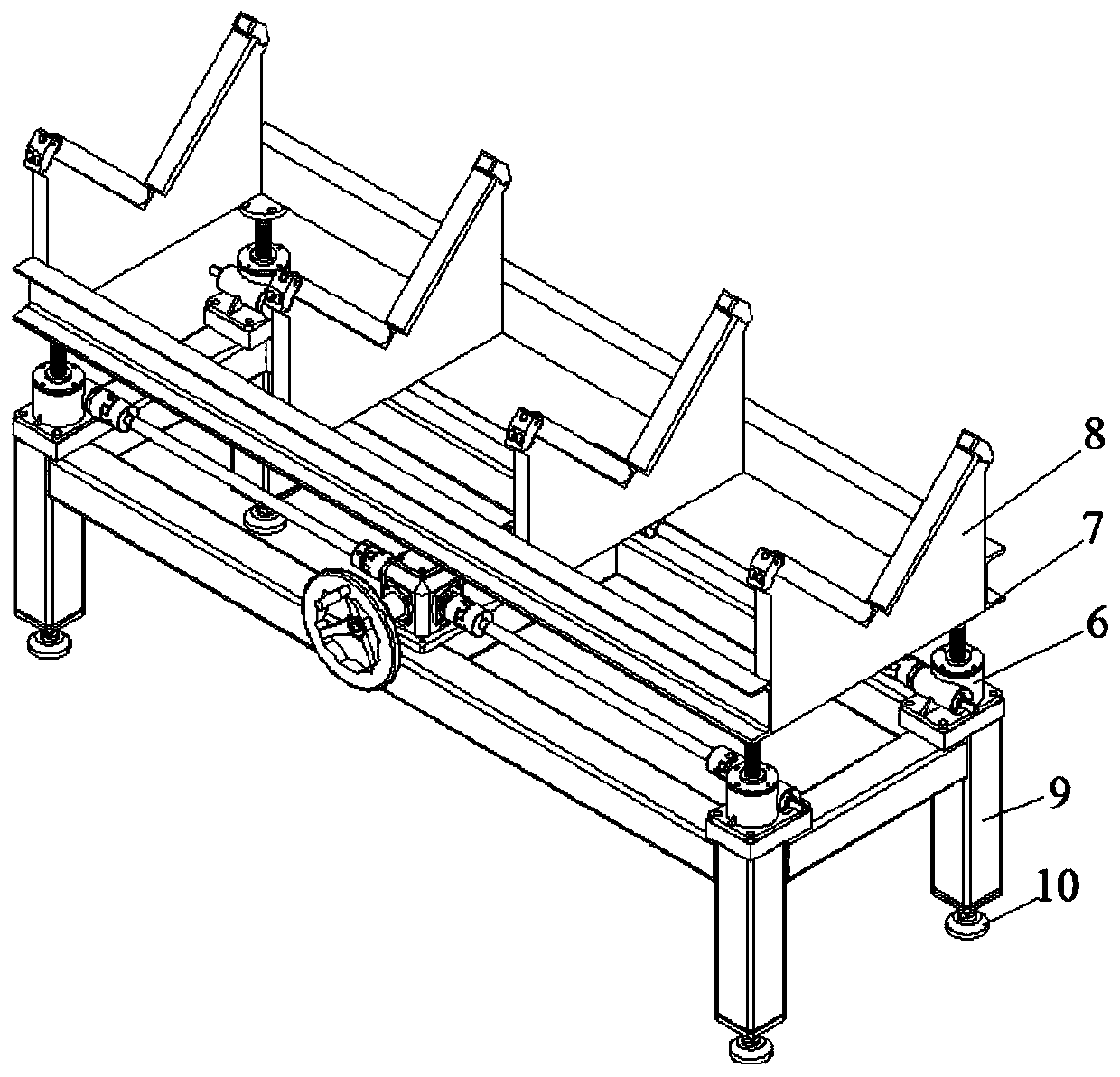

[0025] As shown in the drawings, a lifting platform suitable for supporting large-diameter pipe material loading includes a power unit, a steering gear I2 and a steering gear II3, the power unit is connected to the input shaft of the steering gear I2, and the steering gear I2 Both the left and right output ends are connected with the connecting shaft 4, the rear output end of the steering gear I2 is connected with the input shaft of the steering gear II3, and the left and right output ends of the steering gear II3 are connected with the connecting shaft 4, and the connecting shaft 4 Connected with a worm gear screw lifter 6, at least two groups of brackets 8 for supporting pipes are installed on the upper part of the worm gear screw screw lifter 6, and an underframe 9 is provided on the lower side of the worm gear screw screw lifter 6, and the underframe 9 The lower part is provided with adjusting feet 10. Described worm gear screw elevator 6 comprises housing 64, screw mandre...

Embodiment 2

[0031]As shown in the drawings, a lifting platform suitable for supporting large-diameter pipe material loading includes a power unit, a steering gear I2 and a steering gear II3, the power unit is connected to the input shaft of the steering gear I2, and the steering gear I2 Both the left and right output ends are connected with the connecting shaft 4, the rear output end of the steering gear I2 is connected with the input shaft of the steering gear II3, and the left and right output ends of the steering gear II3 are connected with the connecting shaft 4, and the connecting shaft 4 Connected with a worm gear screw lifter 6, at least two groups of brackets 8 for supporting pipes are installed on the upper part of the worm gear screw screw lifter 6, and an underframe 9 is provided on the lower side of the worm gear screw screw lifter 6, and the underframe 9 The lower part is provided with adjusting feet 10. Described worm gear screw elevator 6 comprises housing 64, screw mandrel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com