Bulletproof watertight door

A door cover and door frame technology, applied in the field of vehicle doors, can solve the problems of large size, non-adjustable, difficult to guarantee, etc., and achieve the effects of reducing processing costs, ensuring processing quality and precision, and simplifying processing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

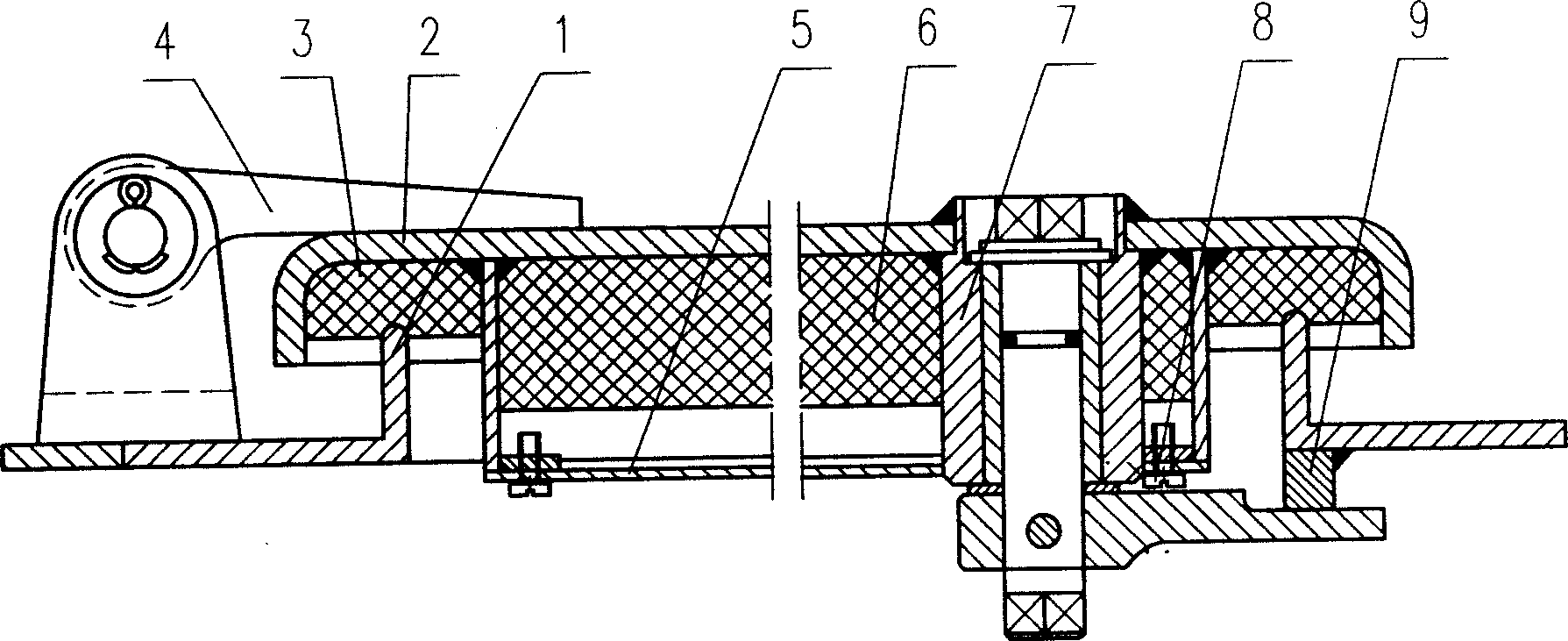

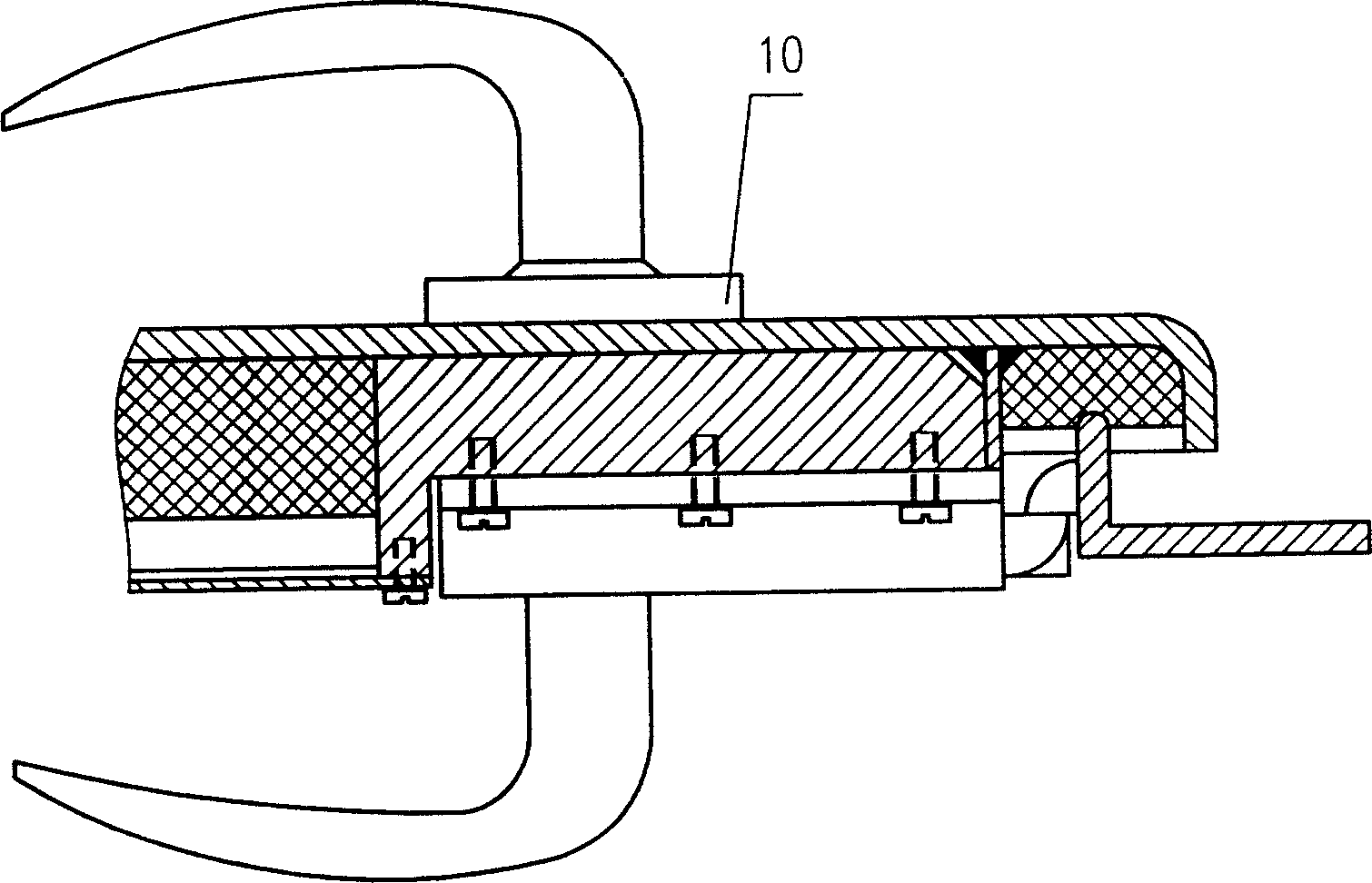

[0011] Such as figure 1 , 2 As shown, the bulletproof watertight door of the present invention is composed of a door frame 1, a door cover 2, a sealing strip 3, a hinge 4, an inner door panel 5, a thermal insulation board 6, a locking mechanism 7, a screw 8, an inclined block 9, a door lock 10 and an adhesive , which is characterized in that: the door frame 1 is fixedly connected with the car body, the door cover 2 is equipped with a sealing strip 3, the inner middle end of the door cover 2 is equipped with a thermal insulation board 6, and the inner door panel 5 is fixed on the vertical rib plate of the door cover 2 by screws 8, Fixing each other as one, one side or the periphery between the door cover 2 and the inner door panel 5 is equipped with a locking mechanism 7, one end of the hinge 4 is connected with the door frame 1, and the other end is connected with the door cover 2, and they are fixed together as a whole, the door frame The lower end of 1 is equipped with incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com