A processing method and device for laser forming and cutting sapphire substrate

A technology of laser forming and processing methods, applied in metal processing, laser welding equipment, metal processing equipment and other directions, can solve the problems of low output energy of short-wavelength laser, low activity of working liquid, difficult forming and cutting, etc., to achieve convenient and practical Processing method and device, ingenious design, good processing quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

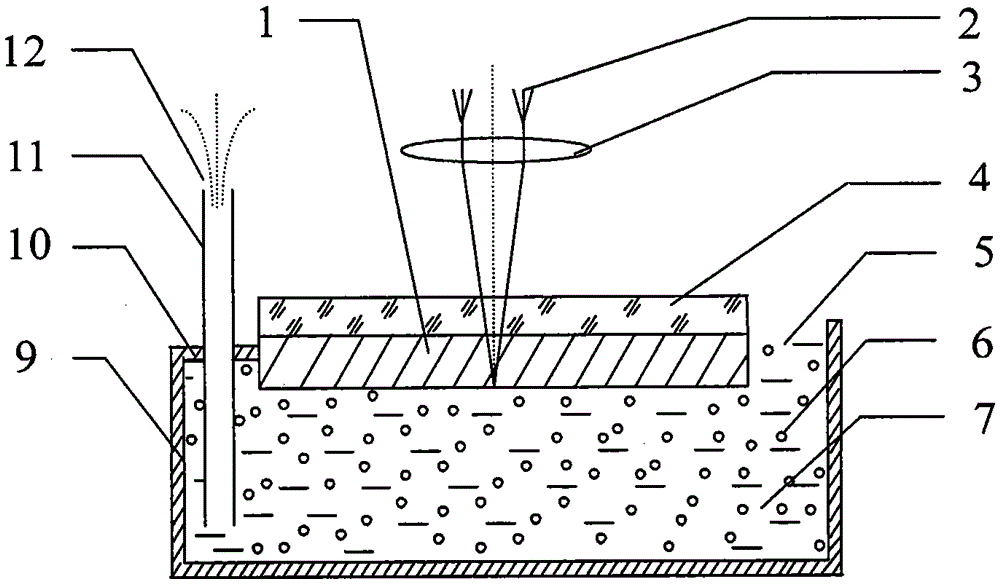

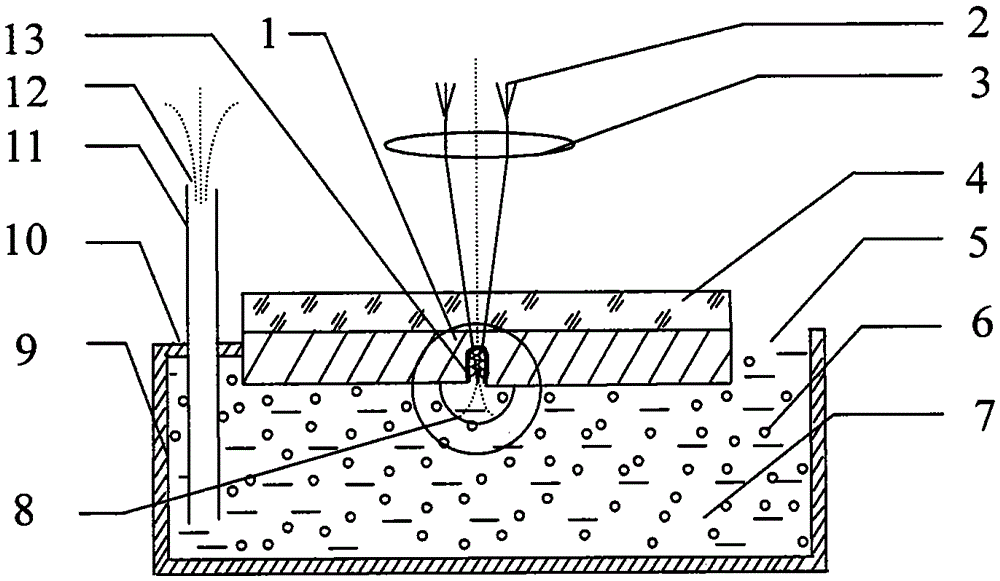

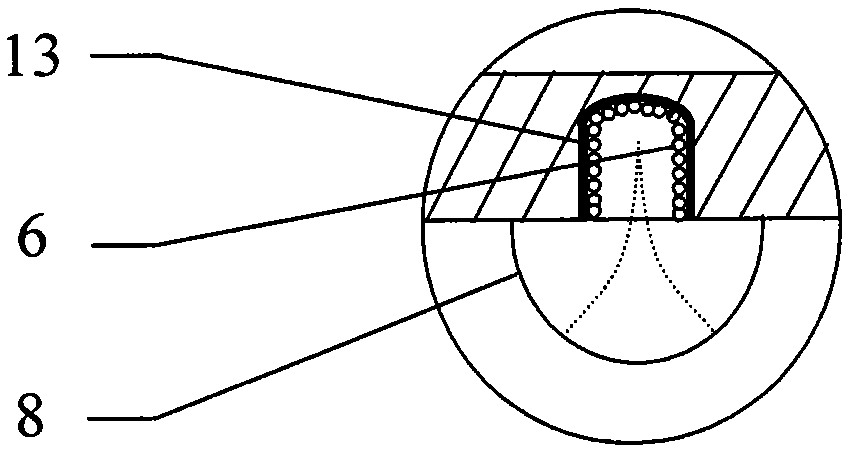

[0026] The processing method of laser forming cutting sapphire substrate of the present invention, comprises the following steps:

[0027] 1) the sapphire substrate 1 is fixed on the top of the container 9 on the workbench, and a protective device 4 is set above the sapphire substrate to prevent the liquid from overflowing from the slit to the upper surface of the sapphire substrate when the sapphire substrate is cut through, Affect cutting quality;

[0028] 2) Inject CuSO into container 9 4 Mix solution 7, and make CuSO 4 The mixed solution 7 is in contact with the lower surface of the sapphire substrate 1;

[0029] 3) focus the laser focus on the sapphire substrate 1 and the above CuSO 4 The contact surface of the mixed solution 7;

[0030] 4) An air inlet pipe 11 is placed on one side of the container, and compressed air 12 is continuously fed in during the processing, and the air pressure is 0.1Mpa, so that the micro-nano particles 6 in the solution are in a suspended ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com