Biological filter material and preparation method

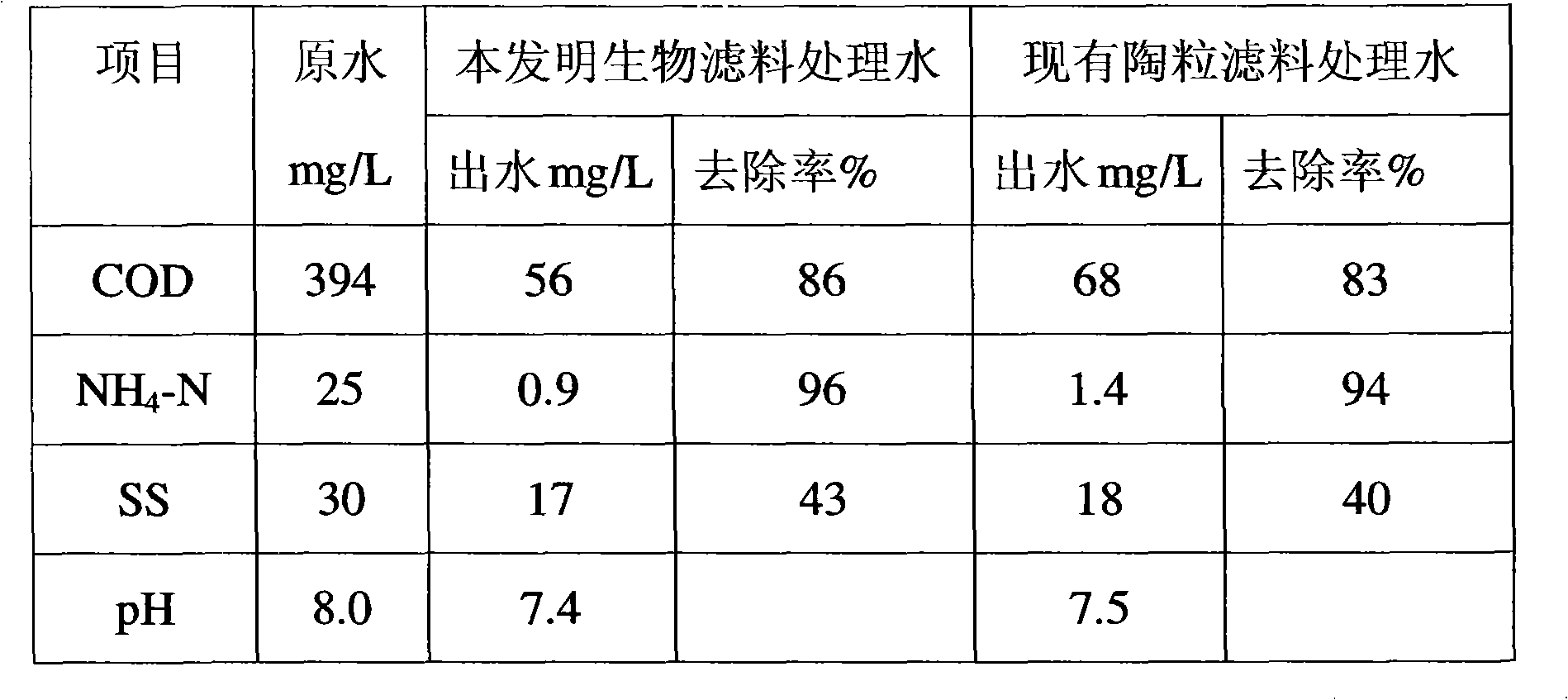

A biological filter material and formulation technology, applied in sustainable biological treatment, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problems of poor gas-water uniformity, poor shearing effect of filter material, and easy detachment of biofilm. , to achieve the effect of low granulation equipment and cost, low filter material cost and good shearing effect

Inactive Publication Date: 2008-10-29

广州市金龙峰环保设备工程股份有限公司

View PDF0 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

(1) Due to the uniform shape and low resistance of the circular filter material, the filter material has poor shearing effect on air and water, and it is difficult for the air and water to be uniform after passing through the filter material layer.

Especially when the filter material is easy to form balls after a period of operation, due to the small resistance between the filter materials, the backwash water gas is easy to flow away locally, resulting in a vicious cycle. Often, the longer the biological aerated filter runs, the worse the uniformity of air and water.

(2) Due to the relatively smooth surface of the circular ceramsite filter material, the micro-bubbles released by the aerator cannot achieve the ideal further shearing effect, but are prone to the phenomenon of bubble pooling, that is, small bubbles collide into large bubbles

The pooling of bubbles has a great influence on the efficiency of oxygenation

(3) During the backwashing process of the round ceramsite filter material, due to the hydraulic shearing effect, the biofilm on the surface is easy to fall off, so the water quality is difficult to achieve the desired effect after a period of time after backwashing

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a biological filtering material and a preparation method thereof. The biological filtering material is prepared from clay 70-80 wt%, fly ash 15-25 wt%, raw coal 3-5 wt% and pore forming agent 0.2-3 wt% by pulverizing clay into 100 mesh; mixing dry powders of clay, fly ash, raw coal and pore forming agent; mixing with water 18 wt% and pelletizing; drying; calcining at 1,050-1,200 DEG C in a kiln; taking out; cooling; sieving; and selecting particles with the diameter of 4-10mm. The biological filtering material has good shearing effect to gas and water, and can prevent bubble aggregation; and compared with ceramsite filtering material, its oxygen utilization is improved by 20-30%. Biomembrane grows the surface of the filtering material and the internal surfaces of pores in a great amount, so influence of backwashing on the internal surfaces of the pores is not great and the quality fluctuation of the discharged water after backwashing is also small. The filtering material is almost spherical and has low pelletizing requirement, and the cost of a pelletizing device and a pelletizing process is relatively low. The prepared filtering material has high strength and void volume.

Description

technical field The invention relates to a filter material for an aerated biological filter. Background technique The biological filter material is the core component of the biological aerated filter. The choice of biological filter material affects the treatment effect and operation control of the biological filter. At present, the filter materials used in the biological aerated filter are divided into inorganic filter materials and organic filter materials. Inorganic filter media are widely used due to the abundant source of raw materials and the ease of large-scale production. Inorganic filter materials include gravel, zeolite, slag, and ceramsite filter materials. Among them, the round ceramsite filter material has been researched and applied more due to its advantages of small resistance and good chemical stability. However, during the use of the round ceramsite filter material, there are some problems as follows: (1) Due to the uniform shape and low resistance o...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C04B33/13C02F3/10

CPCY02W10/10

Inventor 黄亮石云峰陈城池田许华

Owner 广州市金龙峰环保设备工程股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com