Multi-media separated injection system suitable for mine field complex oil reservoir

A multi-medium and medium technology, applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc., can solve the problems of difficult measurement and adjustment, small injection range, equipment corrosion, etc., to achieve enhanced recovery, applicable Wide range, avoid corrosive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

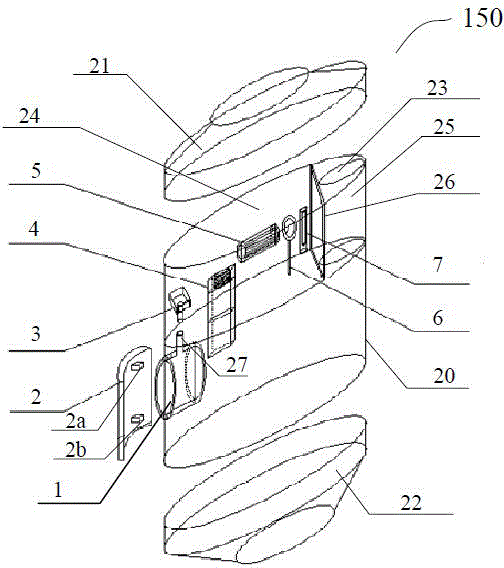

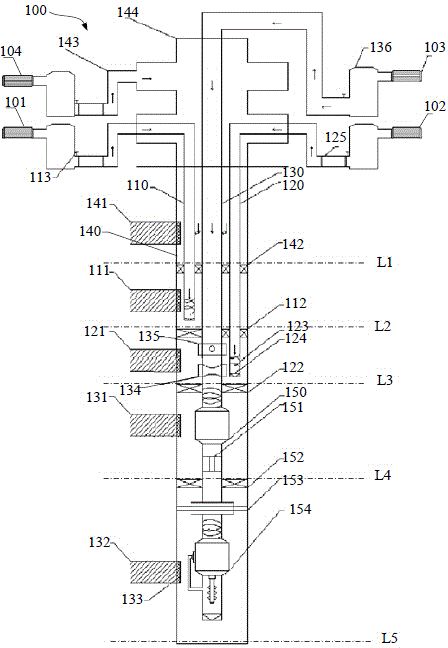

Image

Examples

Embodiment 1

[0083] When there are two or more injection media in different intervals, according to the injection requirements, select the appropriate flow channel according to the layer depth adapted to each flow channel, open the wellhead control valve corresponding to each flow channel, and inject into the pipeline at the same time medium.

[0084] Geological features of a certain block:

[0085] The buried depth of oil in this block is large, and oil layers were found at depths of 1800m, 2200m, 3000m and 3500m. The oil layers are heterogeneous formations, and the physical properties of the oil layers in each layer are quite different: the shallow layer has high permeability and porosity, the formation fluid velocity is high, and the pressure of the overlying rock is much lower than that of the middle and deep layers; the middle layer permeability and porosity Smaller, the formation rock density is higher; the deep section is an overpressure formation, the formation fluid is more, the ...

Embodiment 2

[0106] When there is only one type of injection medium and the interval is relatively single, select the appropriate flow channel according to the depth of the interval adapted to each flow channel, open the corresponding wellhead control valve, and start injecting the medium.

[0107] In this embodiment, the geological characteristics of the oilfield block strata are still selected from the first embodiment. When the well depth reaches 2200m, the oil layer is found. The depth is much smaller. In view of the geological characteristics of this layer, the fourth flow channel is selected in the device of the present invention, and a medium-concentrated high-concentration polymer is injected into the formation to increase the recovery factor.

[0108] Media injection and subsequent monitoring and debugging are as follows:

[0109] (1) Medium injection

[0110] According to the site conditions, analyze the geological data of the formation, select the initial injection pressure an...

Embodiment 3

[0117] When there is only one type of injection medium and multiple layers need to be injected at the same time, multiple suitable flow channels are selected according to the depth of each flow channel, and the wellhead control valves of the respective flow channels are opened to inject the medium at the same time.

[0118] In this embodiment, the geological features of the oilfield block strata are still selected from the first embodiment. Select the overpressure formation in the deep section at 3500 and 3550m, where there are many formation fluids, low flow velocity, low bottom layer density, good electrical conductivity, high permeability and porosity, and it is necessary to inject high-fraction and medium-concentration polymer in the third flow channel ,.

[0119] (1) Medium injection

[0120] According to the site conditions, analyze the geological data of the formation, select the initial injection pressure and injection flow rate, open the third flow channel wellhead c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com