Dividing and cutting machine

A technology of slitting machine and cutting knife, which is applied in textiles and papermaking, metal processing, textile material cutting, etc. It can solve the problems of incomplete cutting, continuous cutting, and material pulling, etc., and achieve improved cutting effect and good cutting effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

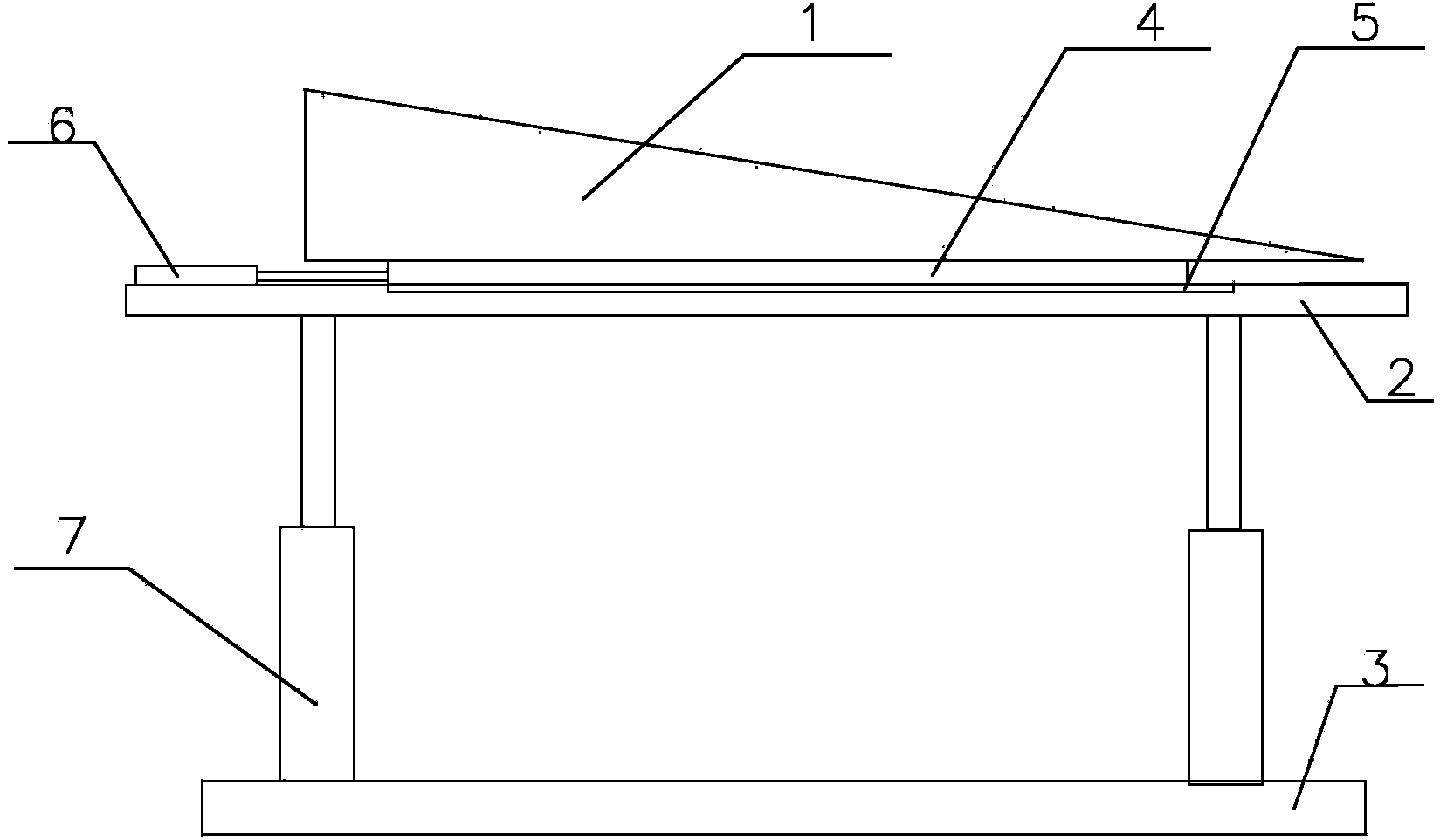

[0021] Embodiment 1: cutting knife 1 is right-angled triangle shape, and long right-angled side is knife back, and knife back is parallel to beam 2 and is connected with beam 2, and hypotenuse is blade, and the length of knife back is longer than the length of needing cutting material.

Embodiment 2

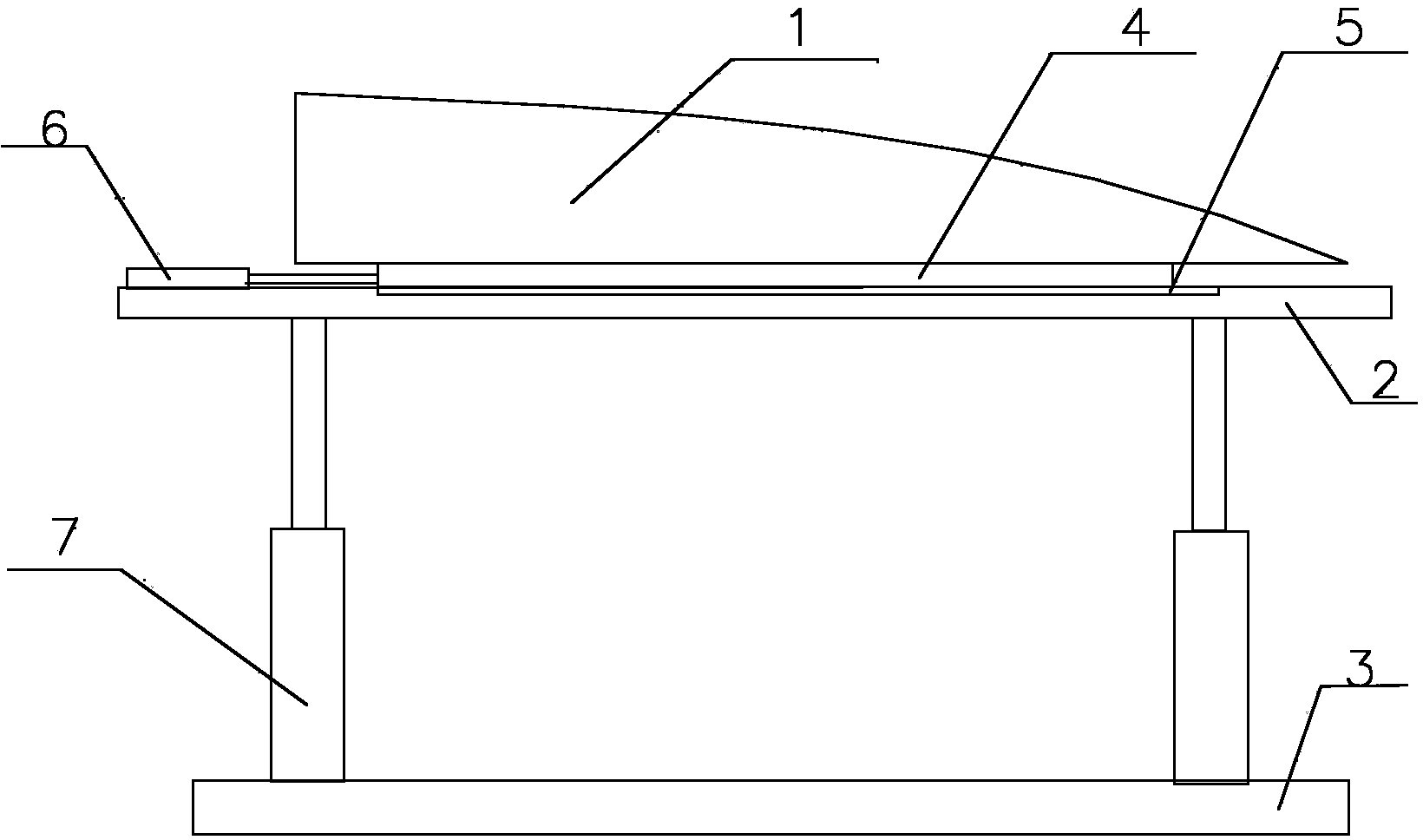

[0022] Embodiment 2: The cutting knife 1 is in the shape of a right triangle, the long right-angle side is the back of the knife, the back of the knife is parallel to the beam 2 and connected with the beam 2, the hypotenuse is convex arc, the hypotenuse is the blade, and the length of the back of the knife is longer than the material to be cut length.

Embodiment 3

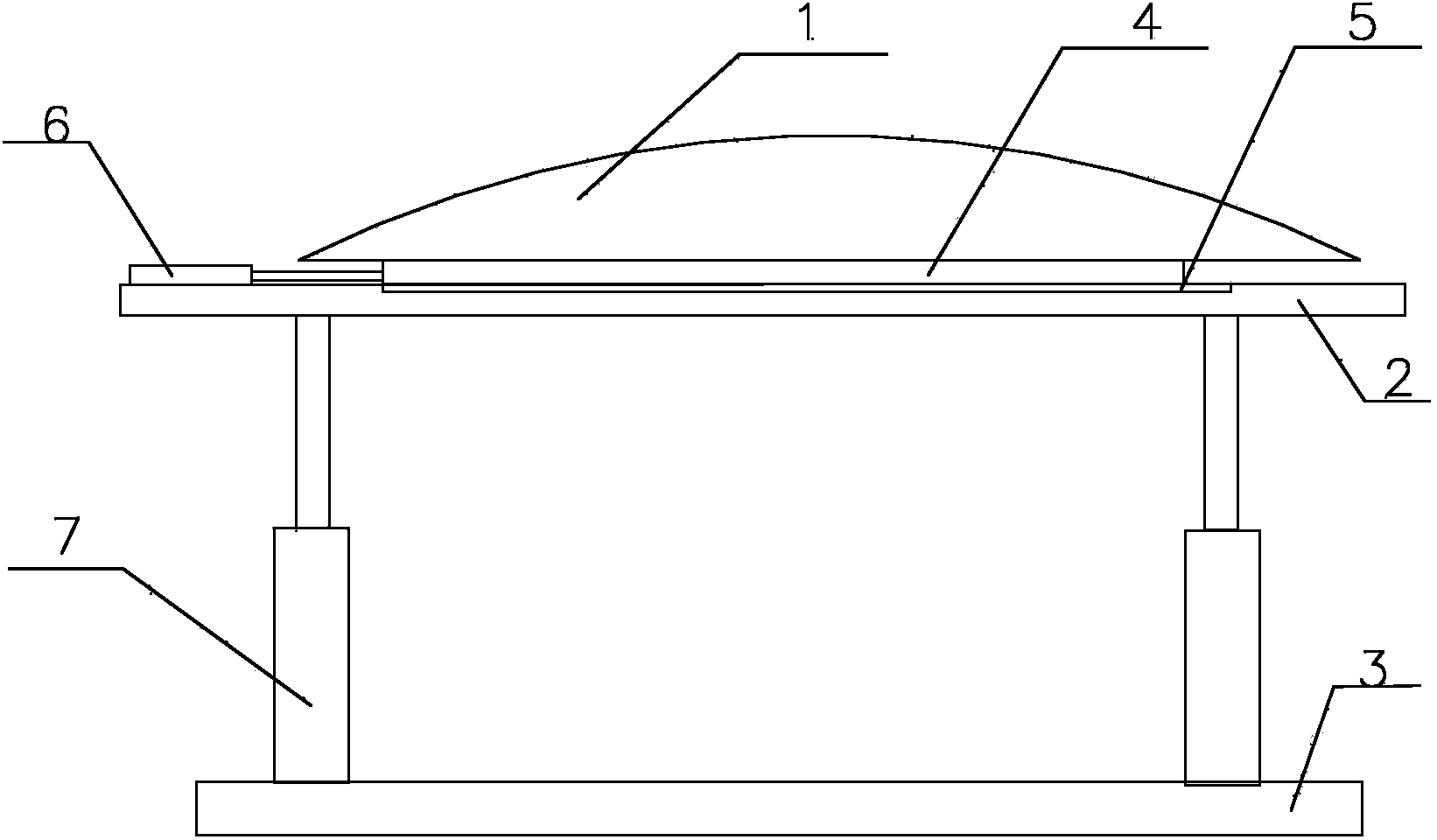

[0023] Embodiment 3: The cutting knife 1 is bow-shaped, the string is the back of the knife, the back of the knife is connected to the crossbeam 2, the arc to which the string is opposite is the blade, and the length of the back of the knife is longer than the length of the material to be cut.

[0024] The first hydraulic cylinder 6 is arranged on the side of the beam 2 away from the blade.

[0025] There are two kinds of implementation modes of power plant, list two kinds of embodiments respectively,

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com