Laser device for cutting

A cutting device and laser technology, applied in the direction of workpiece clamping device, laser welding equipment, metal processing equipment, etc., can solve the problems that cannot meet the needs of high-precision cutting, and the precision of soft board cutting technology is not high, so as to achieve excellent cutting effect, Realize the effect of automation

Active Publication Date: 2008-10-22

HANS CNC SCI & TECH

View PDF0 Cites 47 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the precision of the flexible board cutting technology in the prior art is not high, which cannot meet the market's demand for high-precision cutting

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Frequency | aaaaa | aaaaa |

| Beam diameter | aaaaa | aaaaa |

Login to View More

Abstract

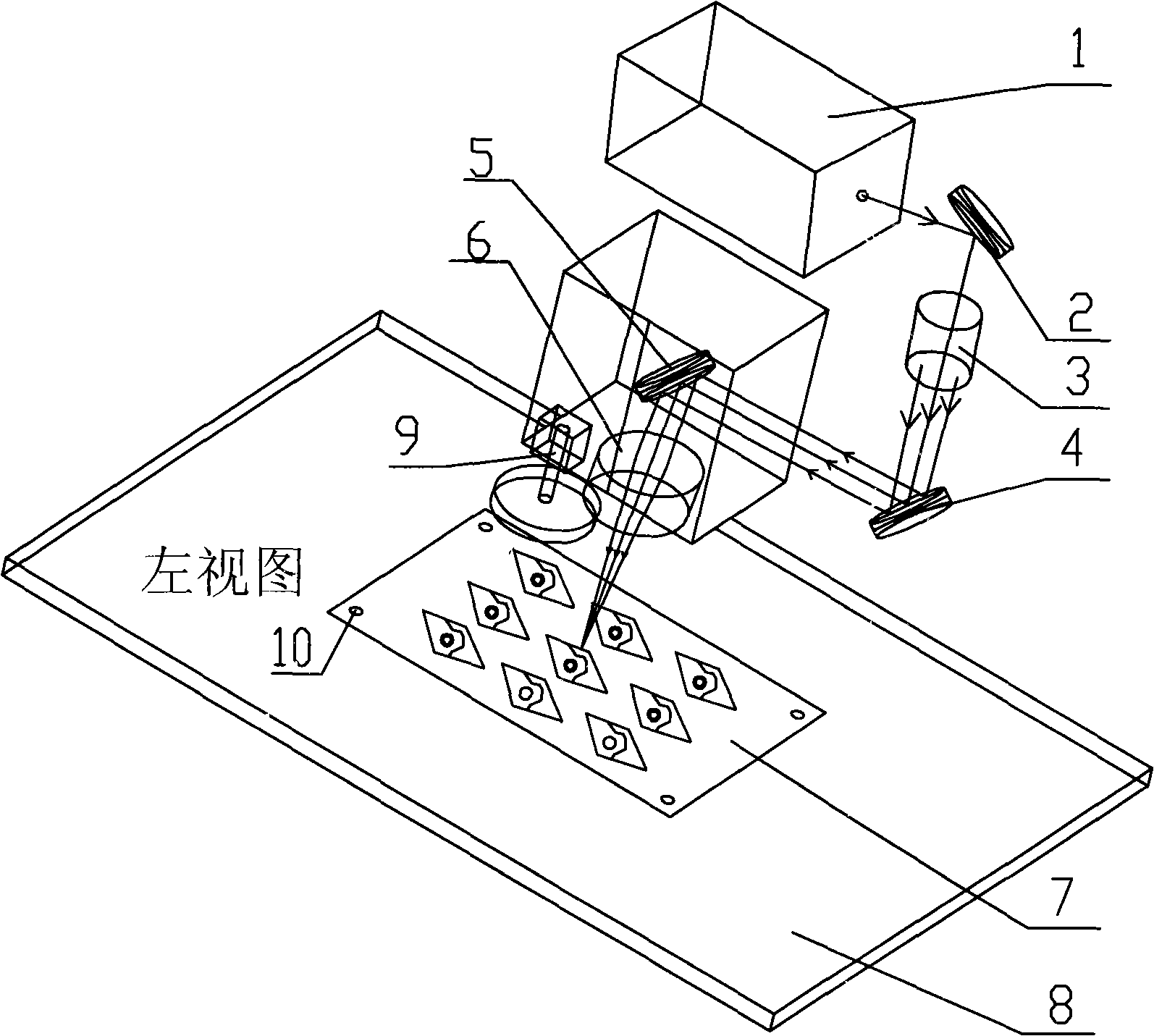

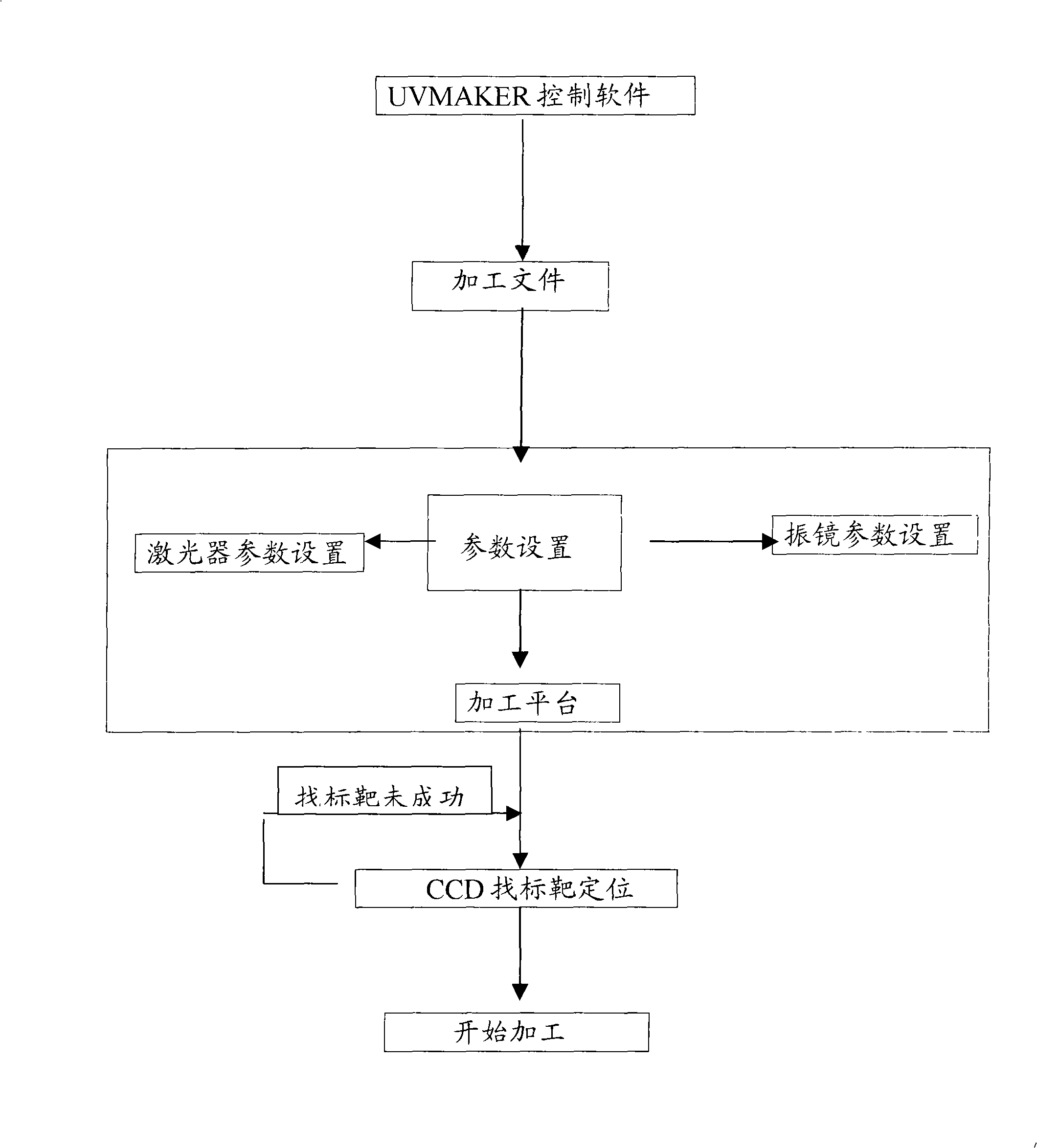

The invention discloses an FPC (Flexible Printed Circuit) laser cutting device, consisting of a laser focus scanning system, a control system and a vacuum platform system. The cutting device of the invention improves the FPC formation accuracy and saves processing time and cost.

Description

Laser cutting device 【Technical field】 The invention relates to a cutting device, in particular, the invention relates to a laser cutting device for a flexible circuit board. 【technical background】 With the trend of miniaturization of machines and instruments, for example, in industries such as electronics, automobiles, aerospace, and measurement and experimental equipment, the output value of FPC (Flexible Printed Circuit) is increasing. The circuit board is cut and formed, and the traditional method is to stamp it with a mold. However, the precision of mold forming is low, the highest can only be controlled at + / -0.05mm, most of them are at + / -0.10mm, and the circuit is often crushed; and the mold production cycle is long, and it cannot be used universally, and needs to be continuously updated. Not on the pace of research and development. Although there are many laser cutting equipment on the market, none of them can meet the requirements of the precision and cutting q...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B23K26/00B23K26/04B23K26/06B23K26/42B23K26/14B25B11/00B23K26/38B23K26/60B23K26/70

Inventor 高云峰雷群翟学涛巢宏兵林小波

Owner HANS CNC SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com