Construction method for building board cutting device

A technology for building boards and cutting devices, which is applied in the direction of shearing devices, manufacturing tools, metal processing equipment, etc., can solve the problems of poor quality of manual cutting, scattering, and large waste of materials, etc., to suppress dust scattering, increase cutting speed, The effect of ensuring breathing safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

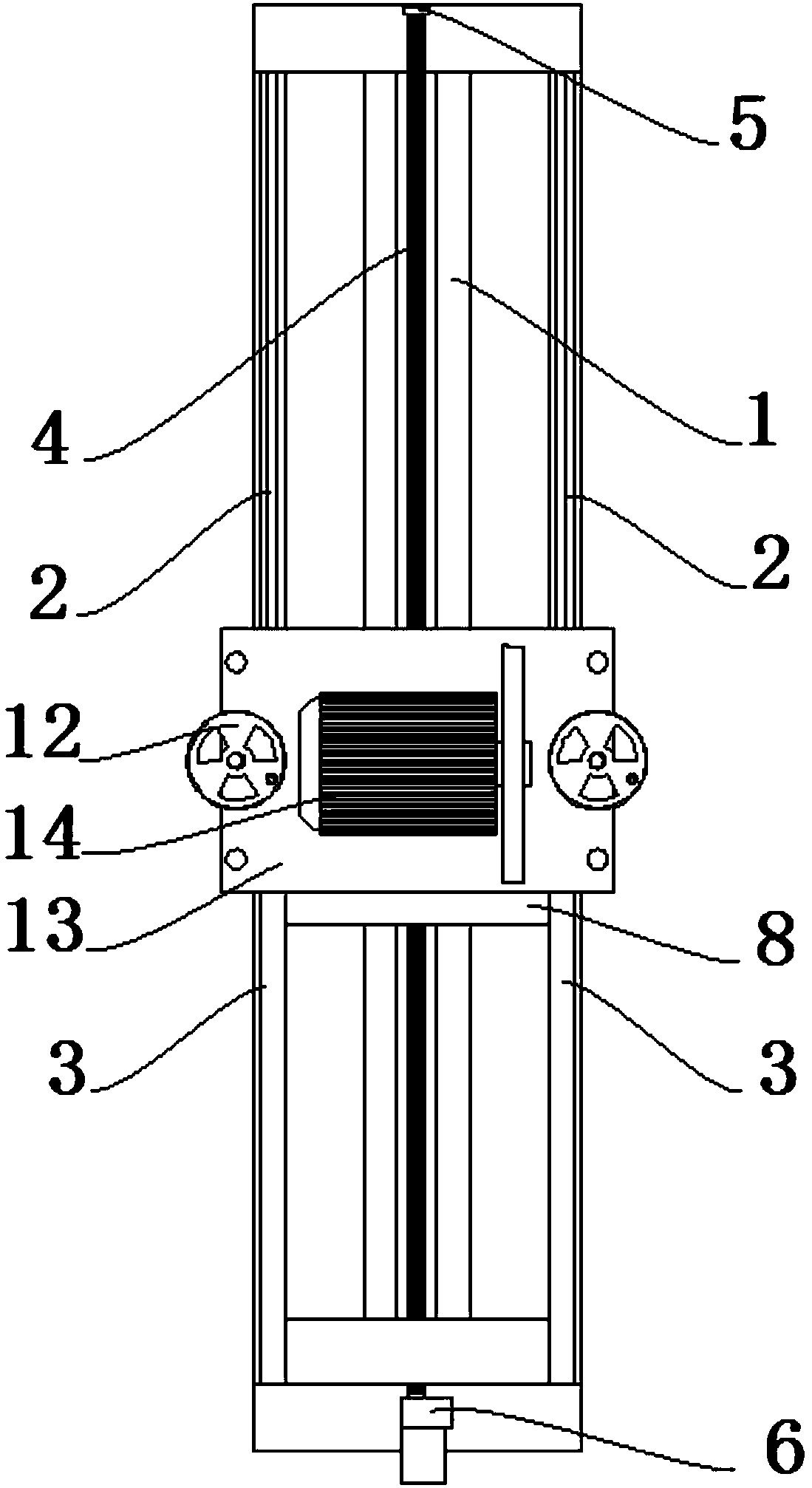

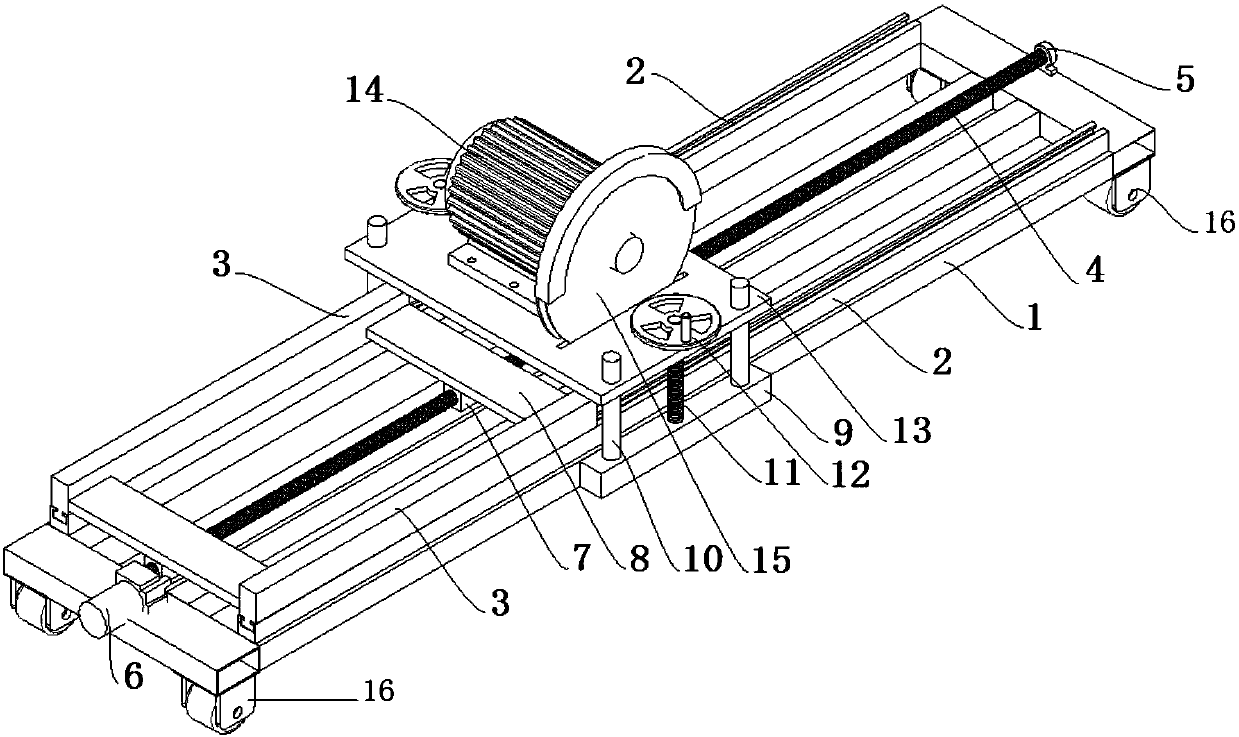

[0030] Such as figure 1 with figure 2 As shown, the present invention is used for the construction method of building plate cutting device, comprises the following steps:

[0031] Step 1. Transport the device to the setting station on the construction site, open the brake device on the casters 16, and fix the device at the setting station;

[0032] Step 2. Move the slider 3 on the guide rail 2, and move the slider 3 to the end of the device;

[0033] Step 3. Take a building board, place the building board flat on the top of the slider 3, mark the cutting line on the building board, and position the building board on the slider 3. The cutting line on the building board is located directly below the cutting piece 15 , fix the building board on the slider 3;

[0034] Step 4, measure the thickness of the building board, manually rotate the handwheel 12, adjust the height of the motor mounting plate 13 by rotating the hand wheel 12 according to the thickness of the building boa...

Embodiment approach

[0043]In a preferred embodiment, the device includes a base 1 and a cutting device. Guide rails 2 are fixedly installed on the left and right sides of the base 1. The two guide rails 2 are located at the same height on the base 1. The guide rails 2 are parallel to each other. The upper ends of the guide rails 2 are respectively A slide block 3 is matched, and screw rods 4 are arranged between the guide rails 2, and the screw rods 4 are parallel to the guide rails 2 respectively. One end of the screw rod 4 is fixedly connected to the base 1 through the screw bearing seat 5 , and the other end of the screw rod 4 is connected to the DC motor 6 through a shaft coupling, and the DC motor 6 is fixed on the base 1 . A screw nut 7 is matched with the screw mandrel 4, and a slider drive plate 8 is fixedly connected to the screw nut 7, and both ends of the slider drive plate 8 are respectively fixedly connected with the slider 3 on the guide rail 2. The top of base 1 is provided with cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com