Operation fault monitoring system and method of construction vertical shaft hanging scaffold winch

A technology for monitoring system and operation faults, applied in the direction of transportation and packaging, load hanging components, safety devices, etc., can solve the problems of high tension of the stable rope, prone to chucking and tilting of the hanging pan, and achieve automation and reliability And the effect of high degree of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

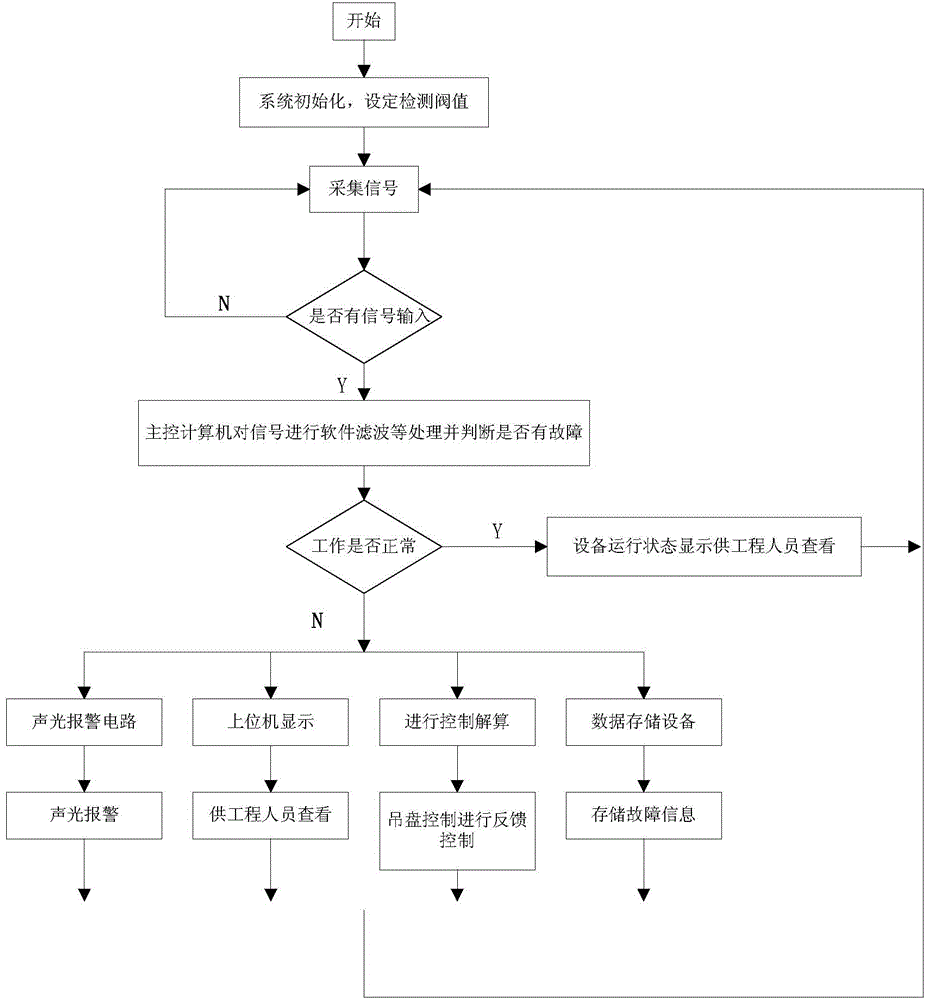

[0021] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

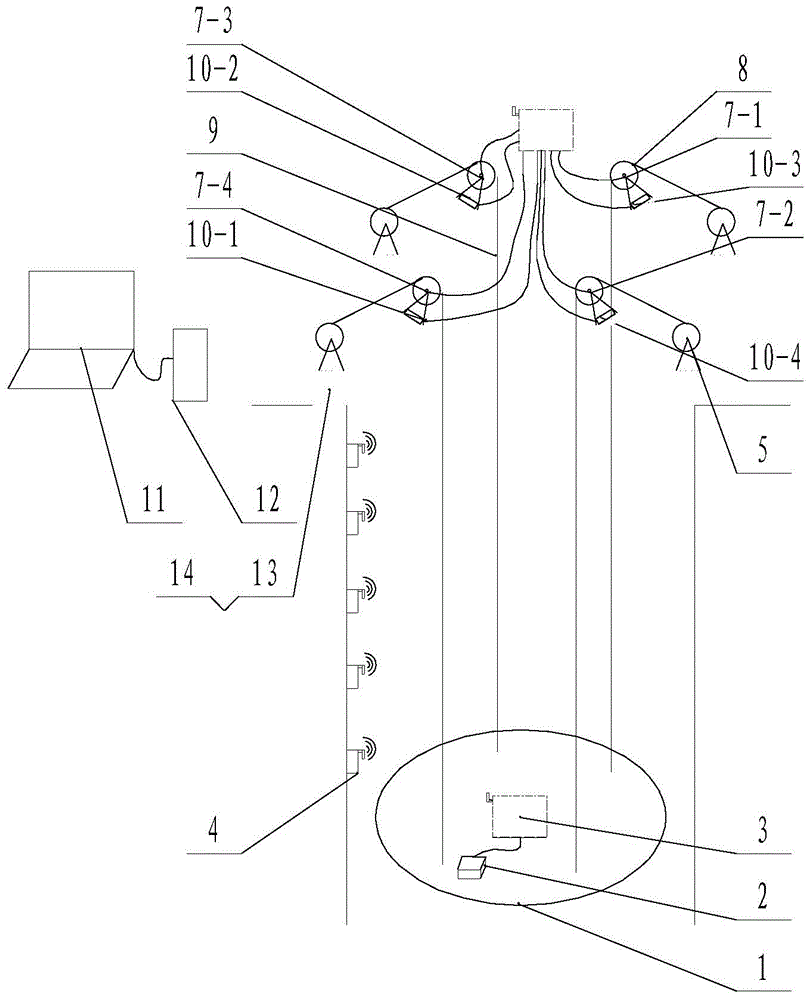

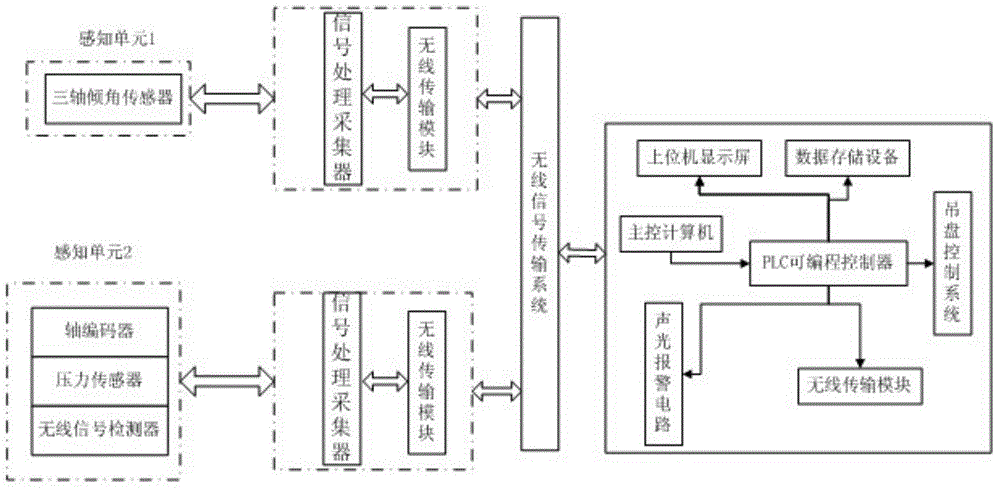

[0022] The system for monitoring the running failure of the construction shaft hanging plate and stabilizing vehicle of the present invention includes the first sensing unit and the first signal processing and acquisition unit arranged on the hanging plate, the second sensing unit and the first signal processing unit arranged on the main shaft of the sky wheel and the base of the sky wheel 2. The signal processing and acquisition unit, the wireless signal transmission system set on the construction shaft wall and the PLC centralized control center set in the control room;

[0023] The first sensing unit is composed of a suspension pan posture sensing unit, and the suspension pan posture sensing unit includes a three-axis inclination sensor 2, which is arranged on the suspension pan 1, and is used to measure the attitude angle of the suspension pan 1 when the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com