Novel punching production line

A production line and a new type of technology, applied in the field of stamping production lines, can solve the problems of low work efficiency and high labor intensity of workers, and achieve the effect of protecting the blade, prolonging the service life and ensuring the quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] Examples: The following specific examples illustrate the implementation of the present invention, and those skilled in the art can easily understand other advantages and effects of the present invention from the content disclosed in this specification.

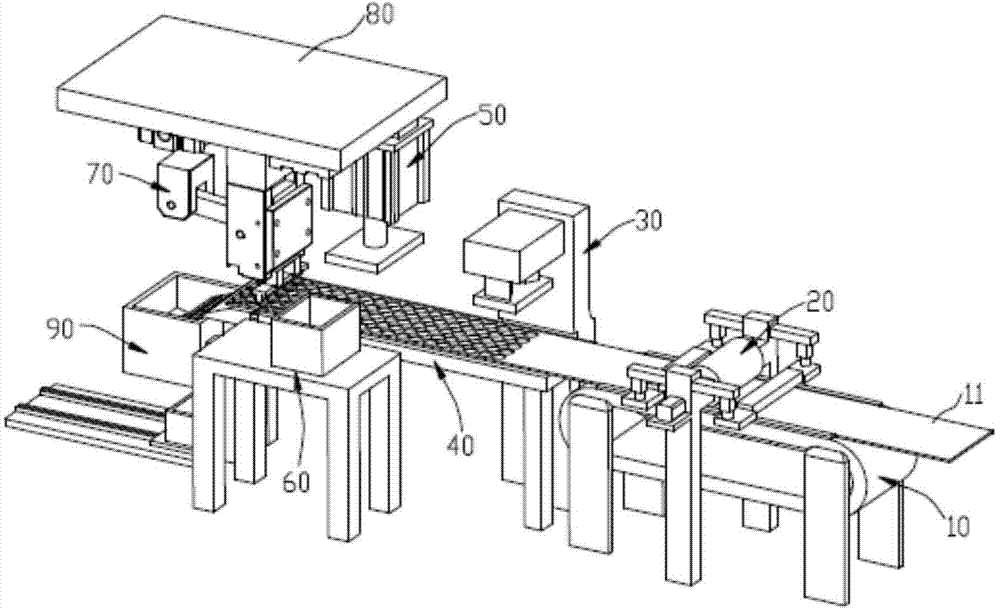

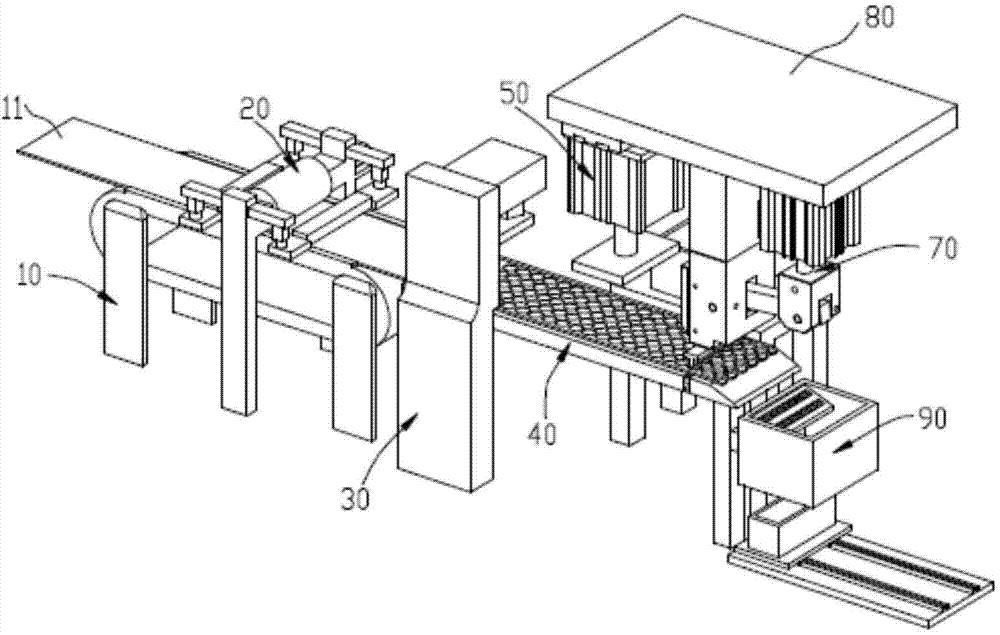

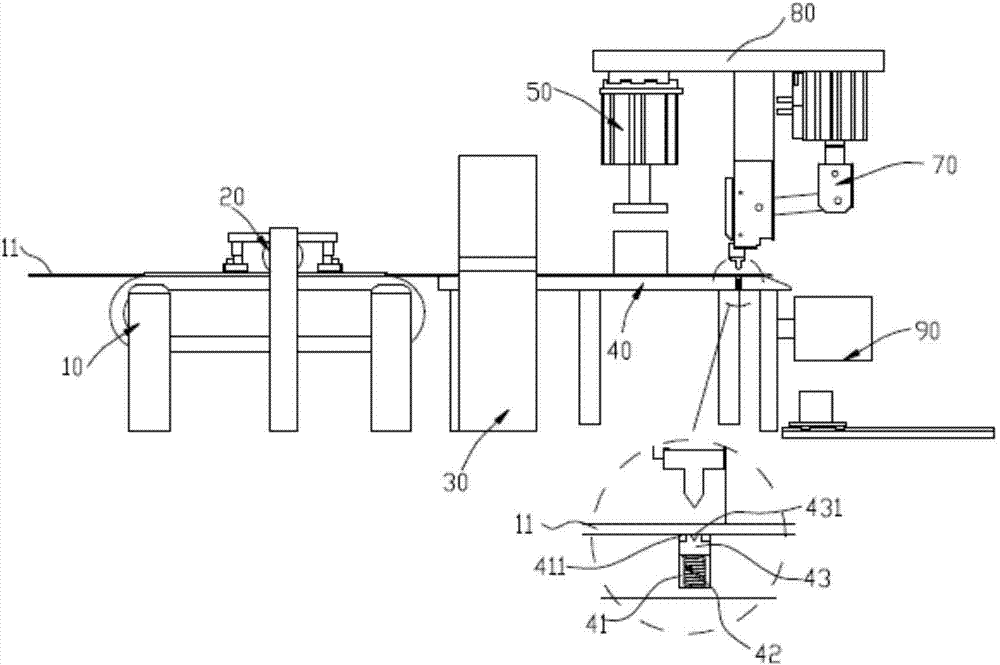

[0027] See Figure 1 to Figure 3 As shown, a new stamping production line includes: a conveyor belt device 10 for driving a steel plate 11 to move, a cleaning unit 20 arranged above the conveyor belt device 10 for cleaning the steel plate 11, a cleaning unit 20 arranged on the conveyor belt The punching table 40 at the discharge port end of the device 10, the punching machine 30 arranged on one side of the punching table 40, is arranged directly above the punching table 40 through the mounting plate 80 and is located at the punching machine 30 away from the conveyor belt The adsorption unit 50 on one side of the device 10, the finished product unit 60 arranged on the other side of the stamping table 40 for placing finis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com