Double-sided heterogeneous glucomannan sponge and manufacturing method thereof

A technology of glucomannan and its manufacturing method, which is applied in the field of manufacturing double-sided heterogeneous glucomannan sponges, can solve the problems of single predetermined roughness, cumbersome process, narrow application range, etc., and achieve shortening of production time and simplification of complex procedures , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

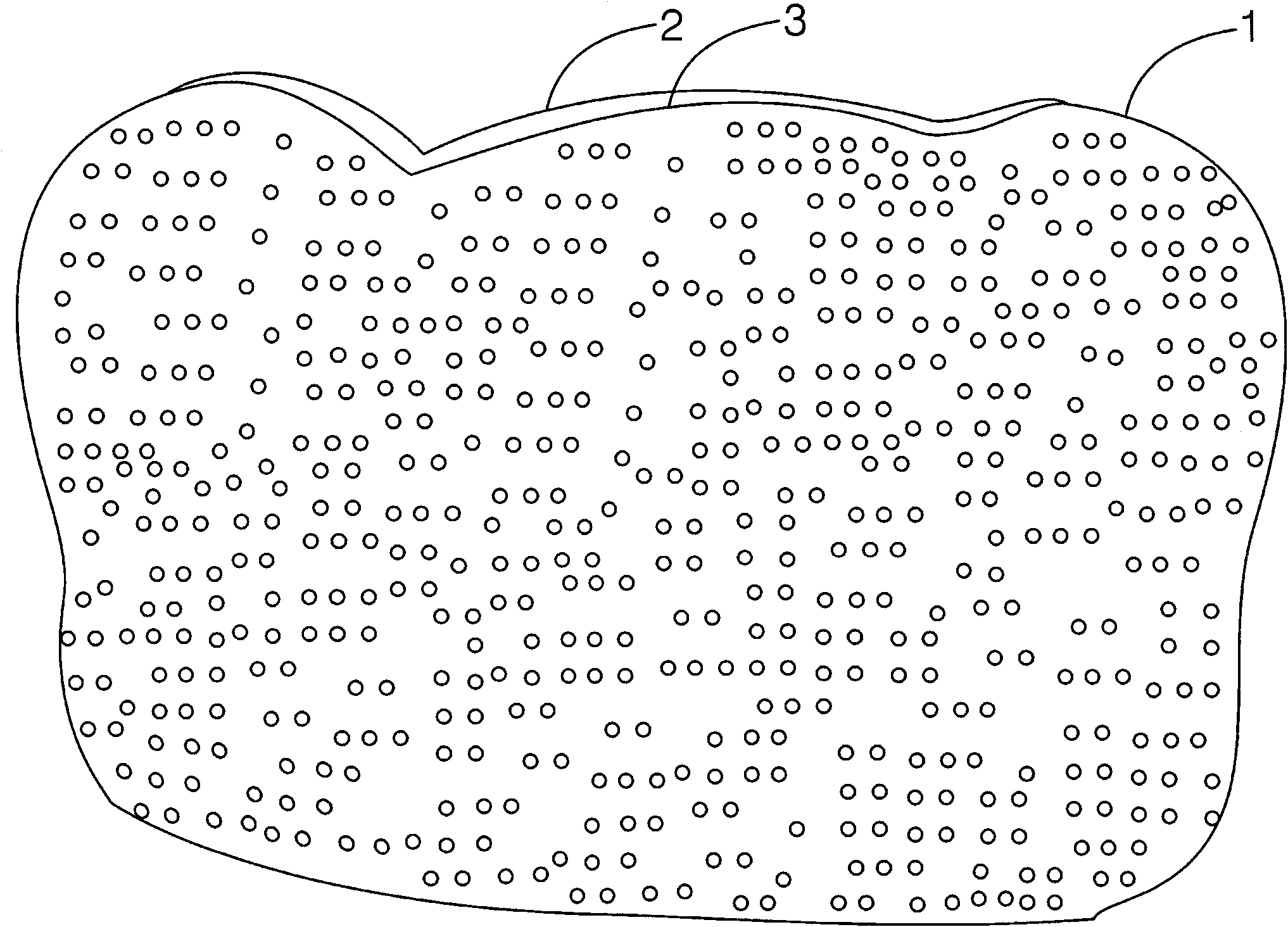

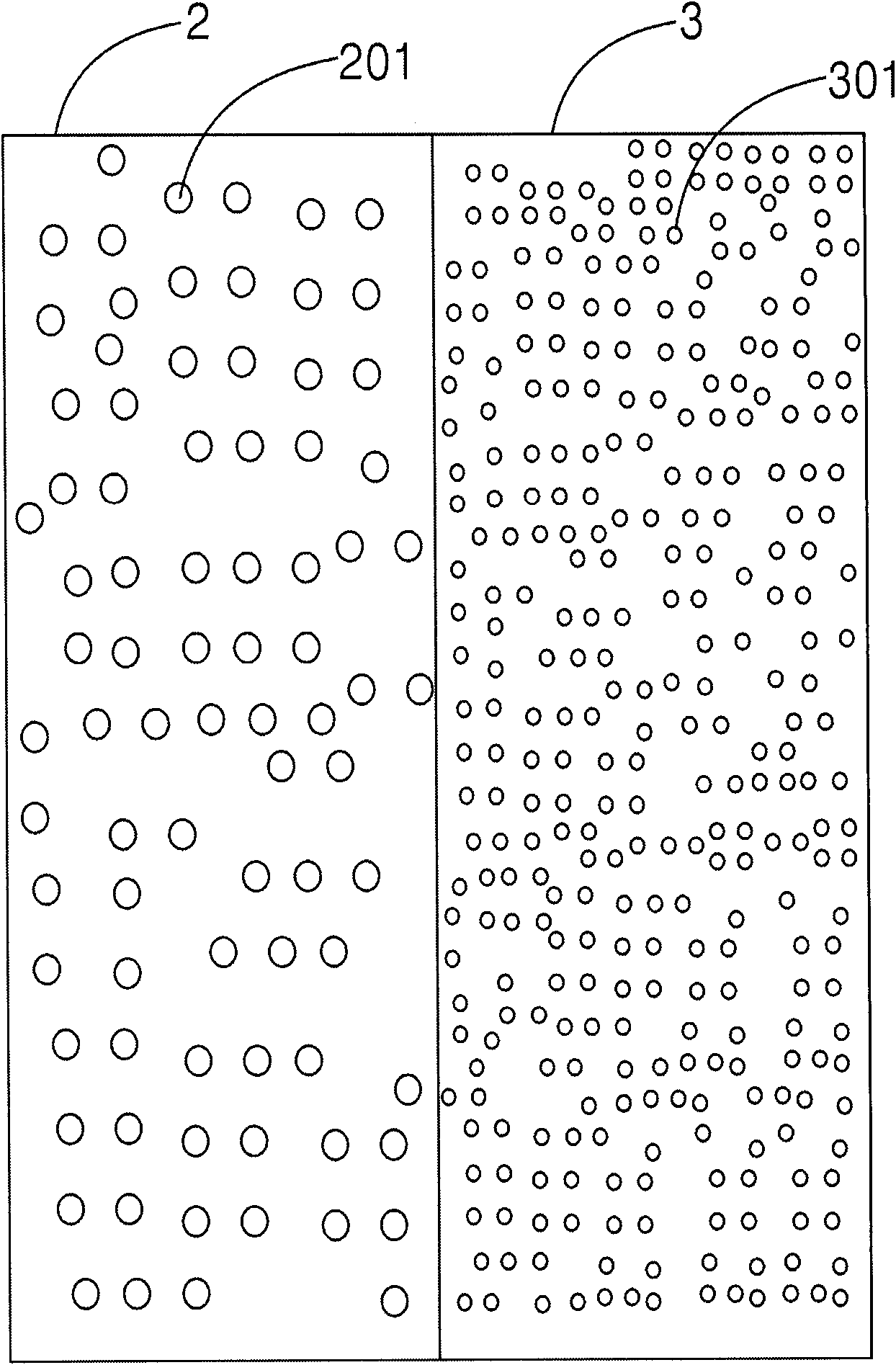

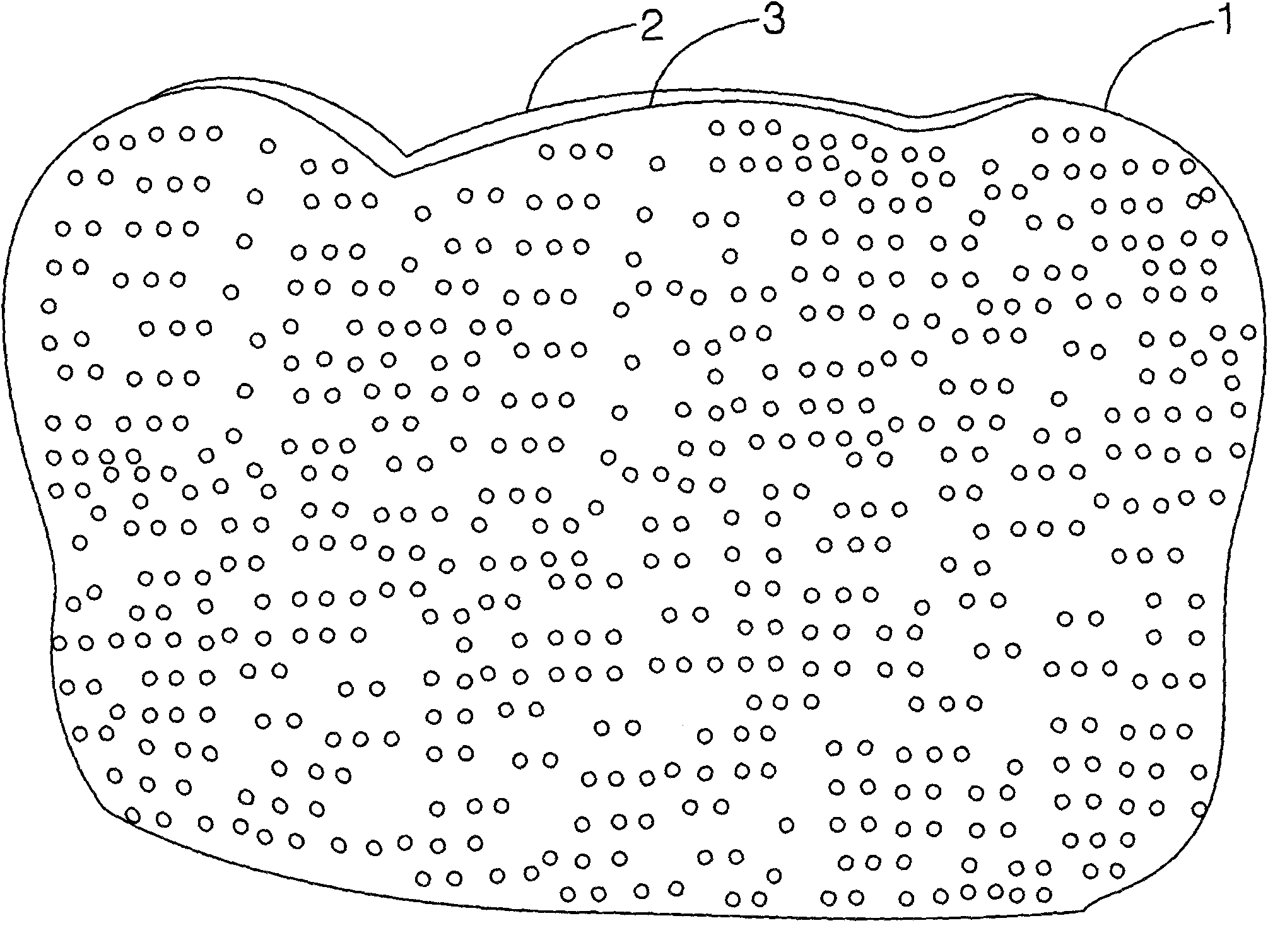

[0032] refer to figure 1 and figure 2 Shown, a kind of manufacturing method of double-sided heterogeneous glucomannan sponge of the present invention, it is to combine 2 glucomannan gels with different reaction times to form a sponge with two kinds of different hole densities, That is to say, the sponge has two surfaces with different roughness, so as to adapt to different skin types of the human body.

[0033] Specifically, the operation steps of this embodiment are as follows:

[0034] A, by edible alkali: hot water=10g: 100g weight ratio, edible alkali is dissolved as alkaline water with hot water;

[0035] b. According to the weight ratio of glucomannan: water = 5g: 100g, mix the glucomannan into the water, and stir it rapidly for 3 minutes to make it into viscous glucomannan fine powder;

[0036] c, by alkaline water: glucomannan fine powder=10g: 100g weight ratio, alkaline water is added in viscous glucomannan fine powder and mix evenly, to remove the glucomannan fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com