System and method for converting steel slag into renewable resources

A technology for regenerating resources and steel slag, applied in the field of smelting, can solve problems such as damage to soil vegetation structure, pollution of air and water bodies, loss of iron-containing resources, etc., to achieve the effect of short process flow, clean site, and small footprint of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiment of the present invention will be described in more detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it after studying this specification.

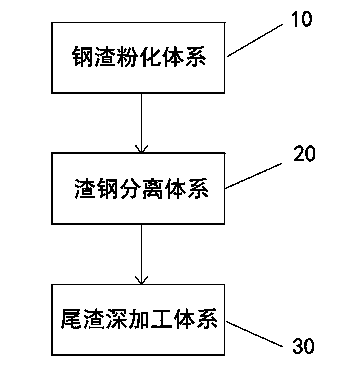

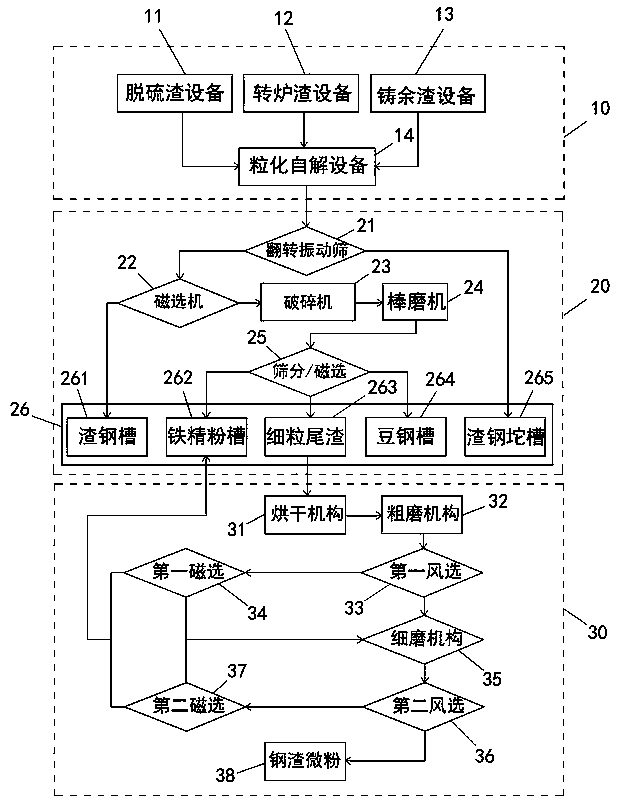

[0024] see figure 1 and refer to figure 2 As mentioned above, a system for converting steel slag into renewable resources according to the present invention includes a steel slag pulverization system 10, a slag-steel separation system 20 and a tailing slag deep processing system 30, wherein:

[0025] The steel slag pulverization system 10 is to pass three kinds of steel slags produced by smelting (such as molten iron desulfurization slag, converter slag and continuous casting slag) through corresponding desulfurization slag equipment 11, converter slag equipment 12 and casting slag equipment 13 respectively, and Carry out the granulation operation in conjunction with the connected granulation self-decomposition equipment 14, so that the three kinds of steel s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com