Novel high-flow emulsion pump station

An emulsion pumping station and high flow technology, which is applied to components of pumping devices for elastic fluids, pump elements, variable displacement pump components, etc., can solve the problems of high manufacturing costs, achieve cleanliness, and improve heat balance point, reduce the effect of fever

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

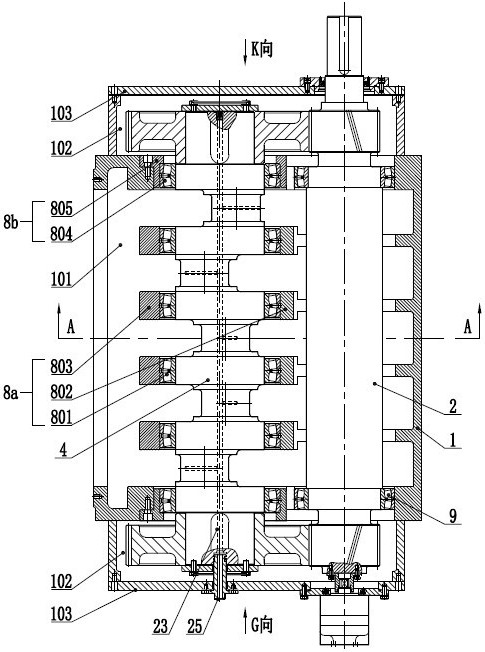

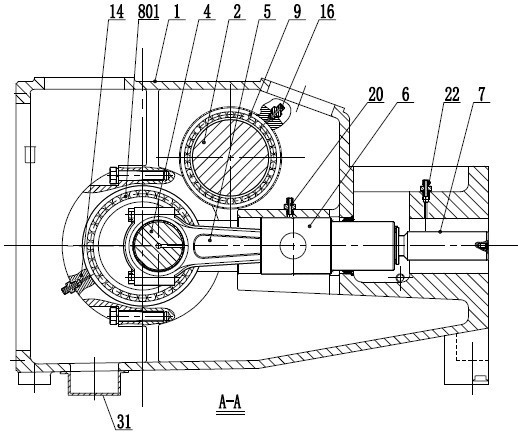

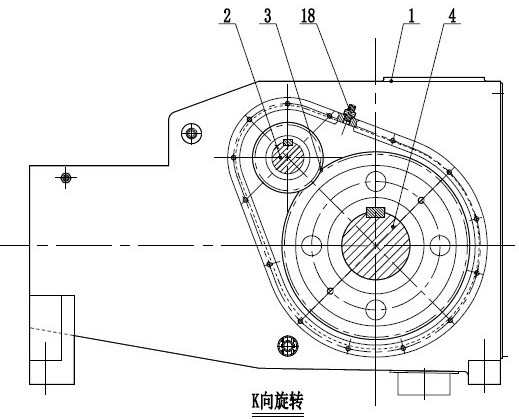

[0032] Such as Figure 1~4 As shown, this embodiment is a horizontal emulsion pumping station with five plungers and six-point support of the crankshaft. This type of emulsion pumping station is composed of a transmission box 1 and many transmission parts in the transmission box, and the transmission zero The components include a power shaft 2, a gear pair 3, a crankshaft 4, a connecting rod 5, a slider 6 and a plunger 7 which are linked in sequence.

[0033] Such as figure 1 As shown, the power shaft 2 is installed in the transmission case 1 through the power shaft bearings 9 at both ends; the crankshaft 4 is installed in the transmission case 1 through the middle support device 8a and the end support device 8b, and the middle support device 8a supports the crankshaft 4 Part or all of the crank journal, while the end bearing 8b supports the front / rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com