Multi-layer co-extrusion cooling pipe and preparation method

A multi-layer co-extrusion and cooling tube technology, applied in chemical instruments and methods, tubes, rigid tubes, etc., can solve problems such as reducing battery life, safety accidents, stress cracking, etc., to improve operational reliability and improve service life. , Excellent corrosion resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040]A kind of preparation method of multi-layer co-extrusion cooling pipe, the preparation of the silane cross-linked high-density polyethylene in the pipe raw material, comprises the following steps:

[0041] S1: Weigh 3~7 parts by mass of catalyst and 93~97 parts by mass of grafting material, optionally, add up to 1 part by mass of masterbatch to make the pipe have a specific color, and mix the mixture of each component evenly ;

[0042] S2: Put the homogeneous mixture obtained in S1 into the extruder, melt and knead it and then extrude it. Among them, the length-to-diameter ratio of the extruder screw is 20~25, the compression ratio (2.5~3): 1; the spiral cooling water temperature is about 60°C ;The mesh number of the filter group is 30-50-100 mesh;The extrusion stretch ratio is ≤2:1;Extrusion temperature: 140°C for the first zone, 175°C for the second zone, 185°C for the third zone, 195°C for the fourth zone, 205°C, die head 210°C;

[0043] S3: Immerse the extruded pro...

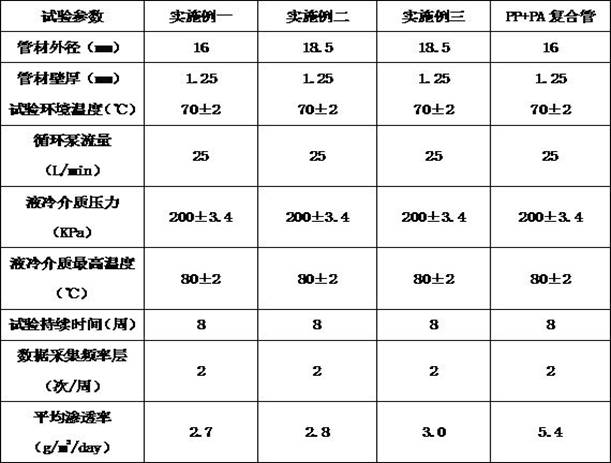

Embodiment 1

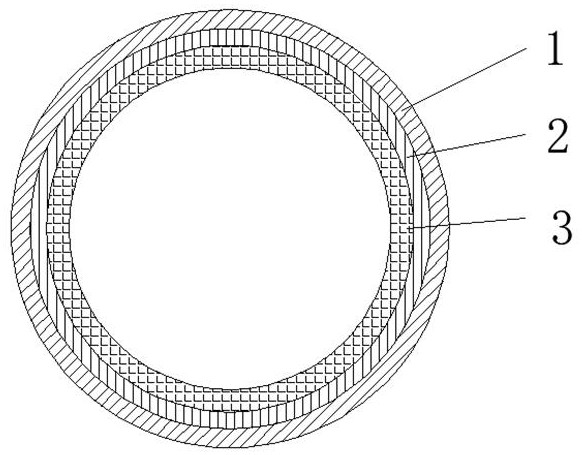

[0055] Multi-layer co-extruded cooling pipes are three-layer structure (see figure 1 ), including a protective layer 1, a bonding layer 2 and a modified HDPE layer 3 arranged in sequence from outside to inside; the protective layer 1 is PA12, and the bonding layer 2 is a commercially available common adhesive resin, modified HDPE Layer 3 is made of catalyst with 7 parts by mass and grafting material with 93 parts by mass; the thickness of protective layer 1 is 0.1~0.5mm, the thickness of adhesive layer 2 is 0.05~0.15mm, and the modified HDPE layer The thickness of 3 is 0.05~0.90mm, the outer diameter of the pipe is 13~18mm, and the wall thickness of the pipe is 0.95~1.40mm.

Embodiment 2

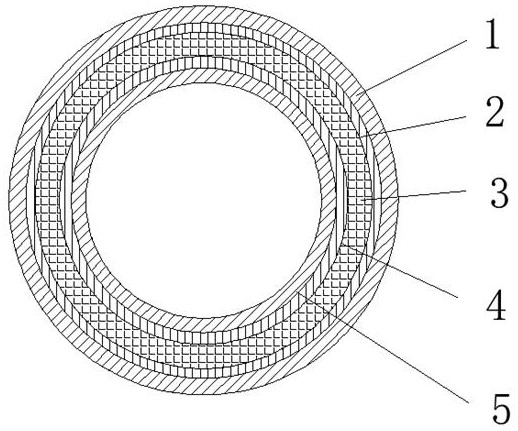

[0057] The multi-layer co-extruded cooling pipe has a three-layer structure, including a modified HDPE layer, a bonding layer and a protective layer arranged in sequence from the outside to the inside; the protective layer is PA12, and the bonding layer is a commercially available common adhesive resin, modified HDPE The layer is made of a catalyst with a mass part of 5 and a graft material with a mass part of 95; the thickness of the protective layer is 0.1~0.5mm, the thickness of the adhesive layer is 0.05~0.15mm, and the thickness of the modified HDPE layer is 0.05~ 0.90mm, the outer diameter of the pipe is 18.5~23mm, and the wall thickness of the pipe is 1.25~1.55mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com