A method for rapidly assembling and disassembling a reciprocating impact tooth to a through hole tooth base and an impacting device with the through hole tooth base with the reciprocating impact tooth capable of being rapidly assembled and disassembled

A technology of reciprocating tooth and through-hole seat, which is applied in the directions of driving device, earthwork drilling, transportation and packaging, etc., and can solve the problems of reciprocating tooth shank falling off, insufficient manpower, and difficulty in moving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

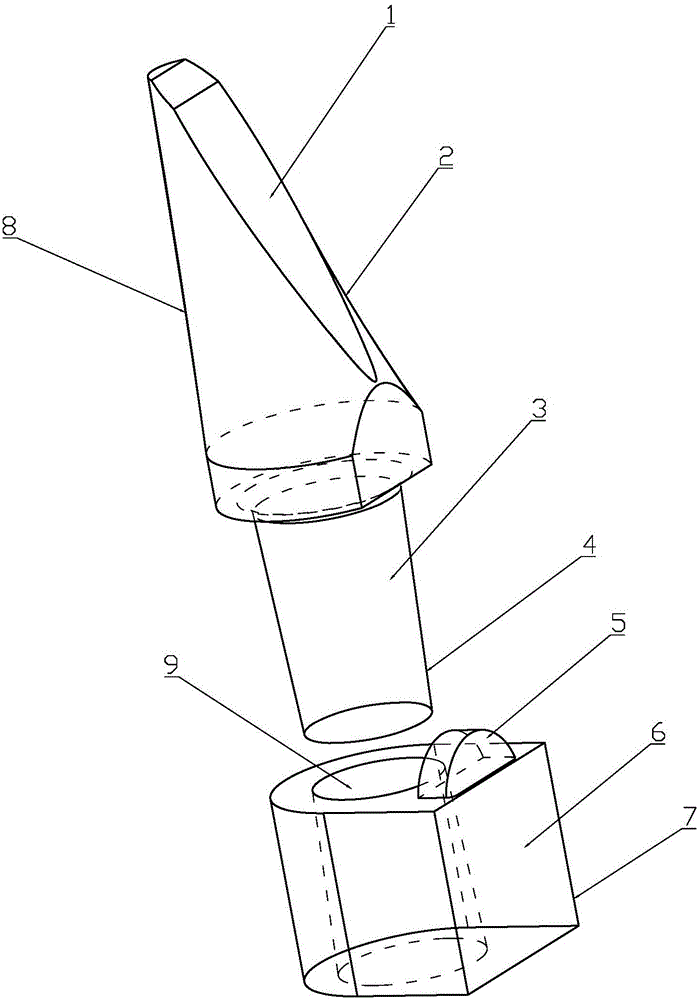

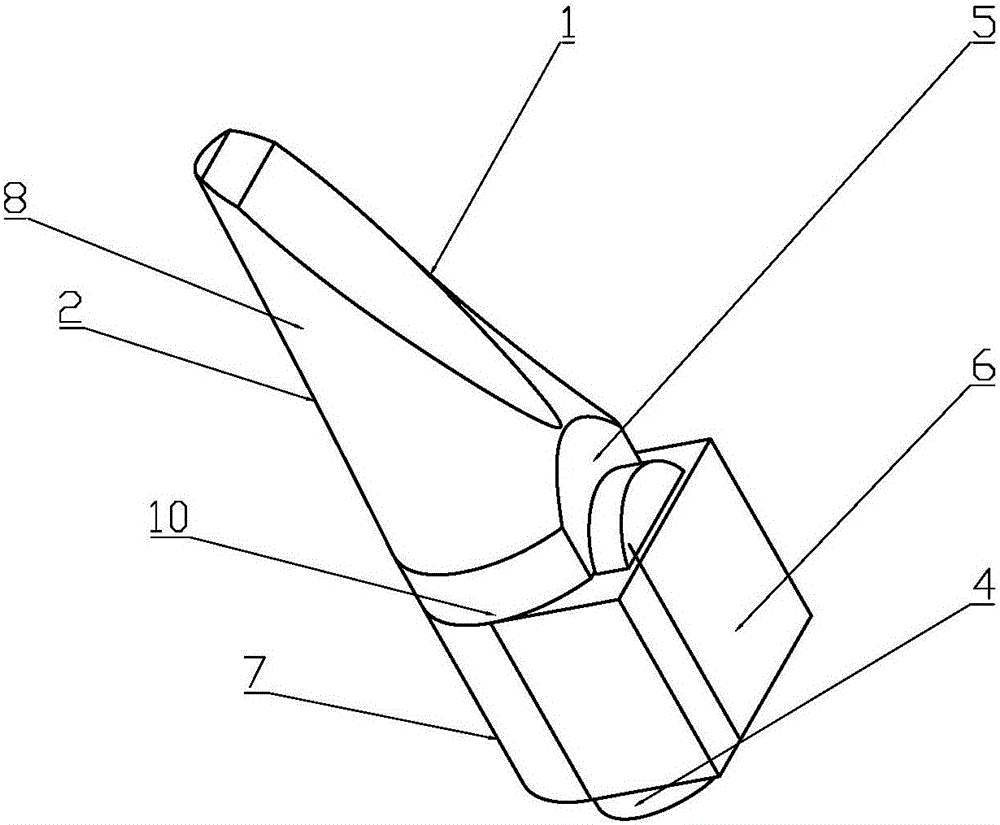

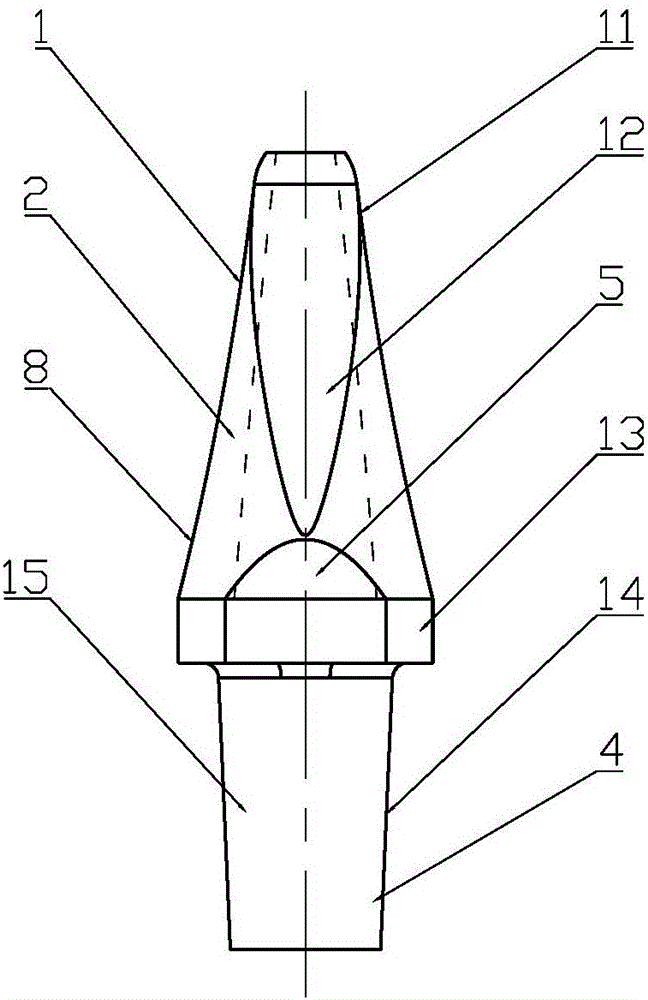

[0115] Figure 1 to Figure 17 The method for quickly installing and dismounting the reciprocating punching gear of the through-hole gear holder described in Embodiment 1 and the quick installation and dismounting of the reciprocating gear punching impact device for the through-hole gear holder, the rapid installation and disassembly of the through-hole gear holder includes a through hole Reciprocating tooth punching 1, reciprocating tooth punching through-hole seat 6, etc., the 6 holes of the reciprocating tooth punching through-hole seat are set in the same direction as the reciprocating punching tooth 1 reciprocating impact direction of the insertion hole, and the rear end of the reciprocating tooth punching 1 includes the insertion hole Hole reciprocating punching tooth handle 4 etc., inserting through hole reciprocating punching tooth handle 4 etc. is arranged on reciprocating punching tooth through hole seat 6 etc., as figure 1 and figure 2 As shown, the reciprocating p...

Embodiment 2

[0129] like Figure 18 and Figure 19 As shown, it is the reciprocating tooth punching impact device for quick installation and disassembly of the through hole gear seat shown in embodiment 2. The difference from embodiment 1 is that the reciprocating tooth punching impact device for quick installation and disassembly of the through hole tooth seat also includes a through hole for removal and insertion. The reciprocating gear puncher 40, the reciprocating impact power guide rod 41, the integrated block seal guide stop box 42, etc. The length of the reciprocating gear puncher 40 for unloading and inserting the through hole is the length of the reciprocating gear punching device 40 for unloading and inserting the through hole from the top tight integrated block seal. The length from the end of the guide anti-rotation box 42 to the rear end of the reciprocating punching handle 4 of the top-tight insertion hole is shorter than that of the rear end of the reciprocating punching too...

Embodiment 3

[0134] like Figure 20 and Figure 21 As shown, it is the quick installation and disassembly of the reciprocating punching gear impact device shown in Embodiment 3. The difference from Embodiment 1 is that the through-hole seat 7 of the oblique cone guide material anti-rotation gear includes a back-stop mechanism 46 and / or Anti-rotation structure 47 etc., such as Figure 20 Shown, oblique cone reciprocating guide material anti-rotation insertion through hole tooth 29 and oblique cone material anti-rotation gear through-hole seat 7 use through-hole reciprocating punching gear backstop 49 etc. to stop retreating, can also be oblique cone reciprocating guide material stop Turn and insert the through-hole tooth 29 and the oblique cone guide material anti-rotation tooth through-hole seat 7 to stop retreating 10 with the cone surface; for the anti-rotation structure 47 as Figure 20Shown, oblique cone reciprocating guide material anti-rotation insertion hole tooth 29 and oblique c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com