Composite drill bit

A composite drill bit and drill bit technology, which is applied in mining engineering, oil and gas drilling engineering, tunnel engineering, and geological drilling fields, can solve the problems of high drilling cost, cutting tooth collapse failure, and cutting tooth impact resistance, etc. Rock efficiency, reduce the probability of tooth chipping failure, and reduce the effect of circumferential vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

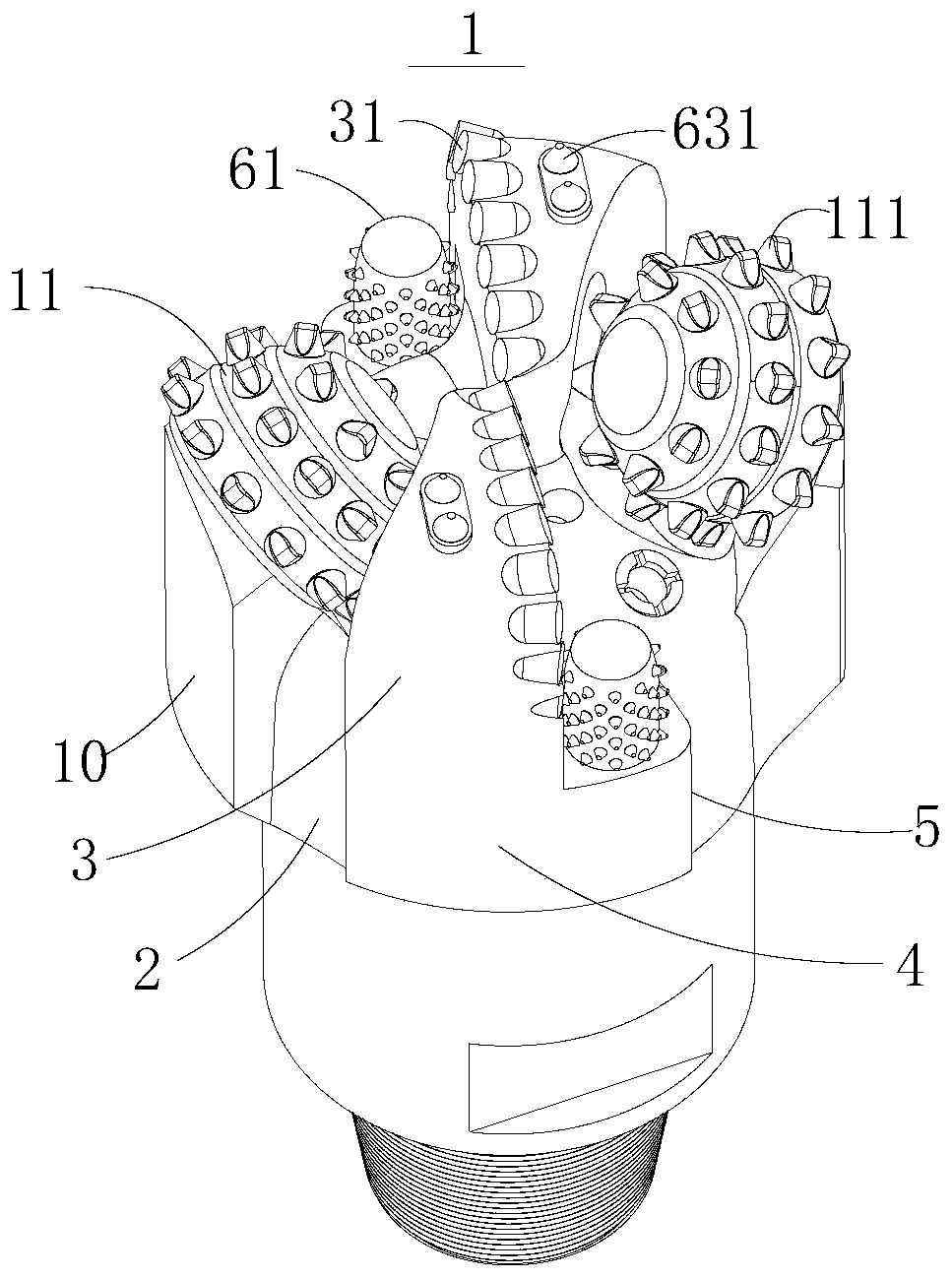

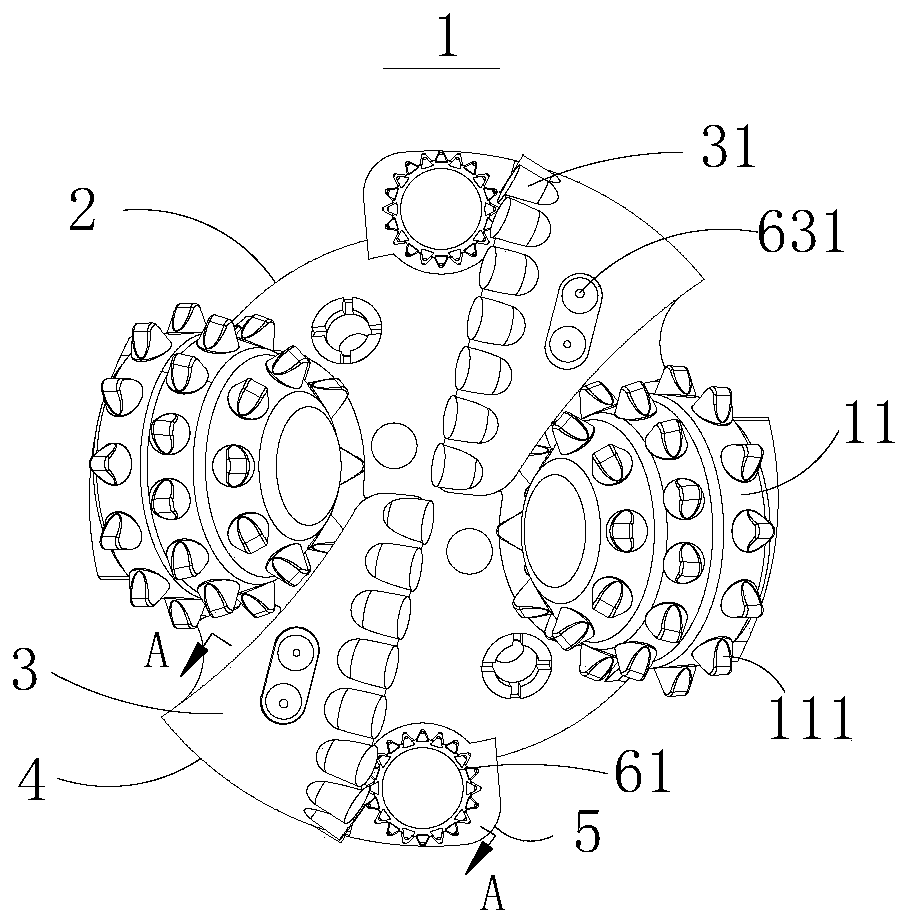

[0041] see Figure 1-Figure 8 , the embodiment of the present invention provides a compound drill bit 1 .

[0042] A composite drill bit 1 includes a drill body 2, a blade 3, a tooth palm 10, and a cone 11. The blade 3 is fixedly connected to the drill body 2 or integrally formed. The blade 3 is provided with cutting teeth 31. The cone 11 and the The tooth palm 10 forms a rotational connection through a shaft, the tooth 111 is arranged on the cone 11 , and the impact unit 6 is arranged on the compound drill bit 1 through the supporting body 5 .

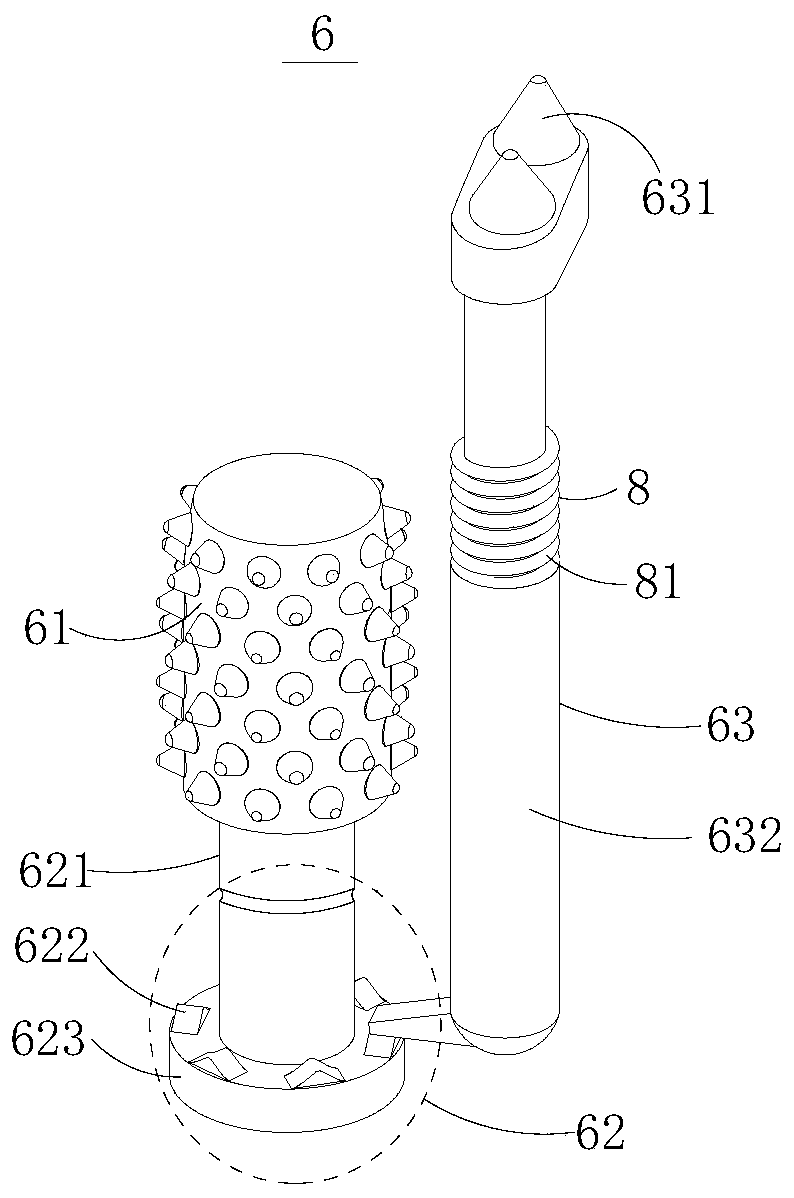

[0043] see Figure 3-Figure 6 , the impact unit 6 is made up of rolling body 61, transmission device 62 and impact device 63; Image 6 ) The distance between the outer contour 610 of the rolling element 61 and the blade gauge line 40 in the radial direction is L, and its range is -d / 4≤L≤d / 4, where d is the diameter of the cutting tooth; the impact device 63 consists of an impact The rod 632 is composed of at least one impact tooth 6...

no. 2 example

[0053] The embodiment of the present invention provides a composite drill bit, the structure of this PDC drill bit 1 is basically the same as that of the PDC drill bit 1 in the first embodiment, the difference is: please refer to Figure 9 , in this embodiment, the transmission device 62 is a gear mechanism, including a transmission shaft 621, a transmission gear 91, a driven gear 92, and a convex body 622 on the driven gear 92, and the transmission shaft 621 is fixedly connected or integrally formed with the rolling body 61 , the transmission gear 91 is fixedly connected with the transmission shaft 621 or integrally formed. During work, the rolling body 61 drives the transmission shaft 621 and the transmission gear 91 at the bottom end of the transmission shaft 621 to rotate, the driven gear 92 meshes with the transmission gear 91 and rotates, the convex body 622 on the driven gear 92 and the impact in the impact device 63 The rod 632 forms a cam pair to realize the impact of...

no. 3 example

[0055] see Figure 10-Figure 12 , a composite drill bit 1, comprising a drill body 2, a blade 3, a tooth palm 10, and a cone 11, the blade 3 is fixedly connected to the drill body 2 or integrally formed, and the blade 3 is provided with a cutting tooth 31, a cone 11 It forms a rotational connection with the tooth palm through a shaft. The tooth 111 is provided on the cone 11. The drill bit 1 has at least one tooth-setting blank area 7 around the center of the drill bit. The impact unit 6 is provided on the blade 3.

[0056] Impact unit 6 is made of rolling element 61, transmission device 62 and impact device 63; Rolling element 61 can rotate around its own axis and is arranged in the rolling groove 30 of blade 3; Impact device 62 is made of impact rod 632 and at least one impact tooth 631 Composition; the rotation of the rolling body 61 can realize the impact of the impact device 63 toward the radial direction of the drill bit 1 through the transmission device 62 .

[0057] I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com