Transmission system of a vehicle-mounted drilling and repairing machine

A transmission system, drilling and repairing machine technology, applied in the direction of drill pipe, drill pipe, earthwork drilling, etc., can solve the problems of large overall width of the drawworks, affecting the announcement and driving of the main truck, and the width of the whole vehicle cannot be satisfied, etc., to achieve structural It is compact, improves the transmission efficiency and reliability of the winch, and reduces the working torque of the auxiliary brake.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

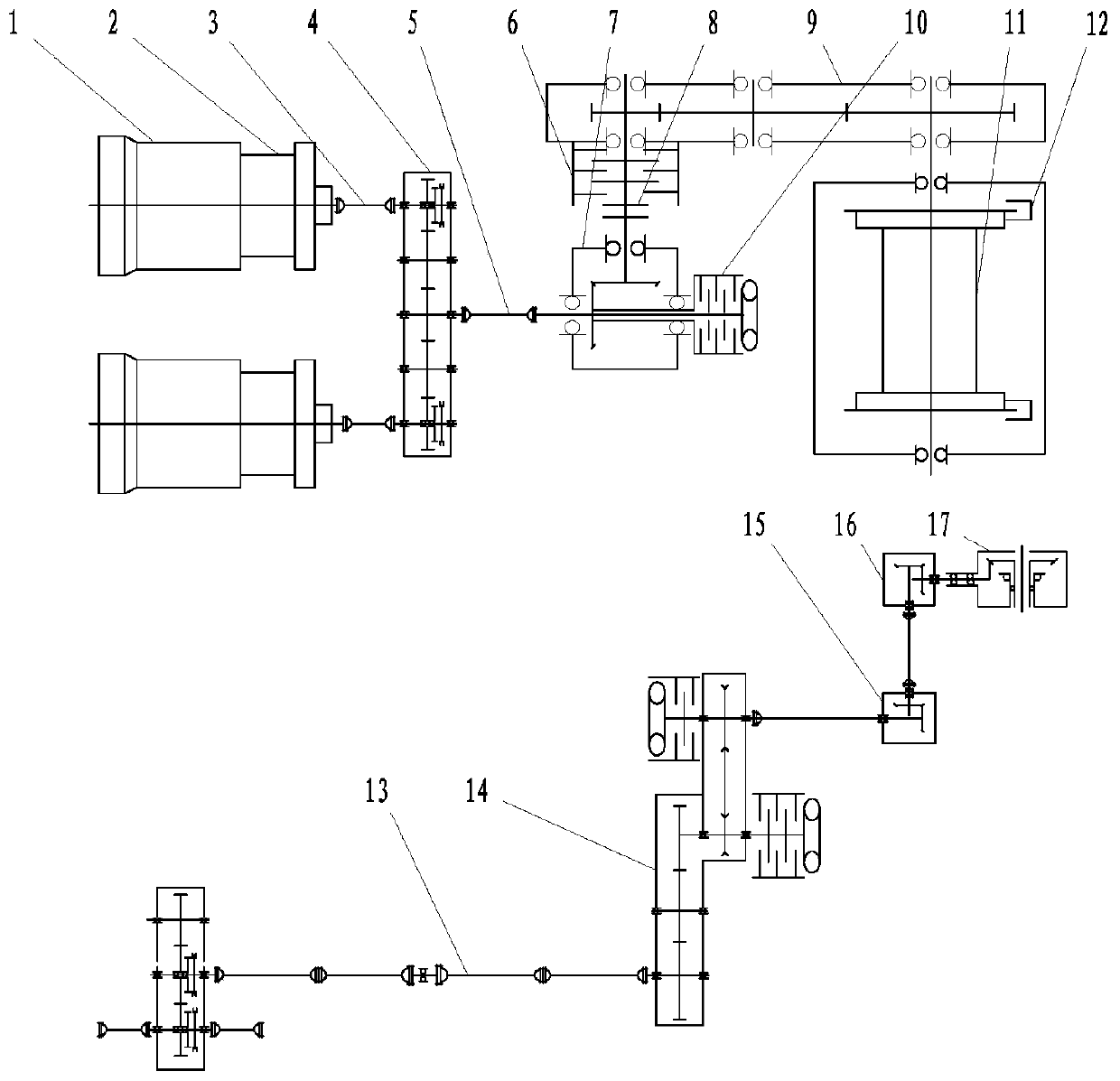

[0019] The main transmission route of a vehicle-mounted drilling and repairing machine transmission system of the present invention is shown in figure 1 , specifically: the engine 1 and the hydraulic gearbox 2 are connected through the flywheel housing to form a power machine, the power output by the hydraulic gearbox 2 is input into the parallel transfer case 4 through the first coupling 3, and is divided into 4 points by the parallel transfer case The output is three-way power output, and the transfer case 4 drives the cardan shaft 5 through the winch to connect the angle transmission box 7, and the angle transmission box 7 connects to the gear transmission box 9 through the second coupling 8, and one of the power drives the universal shaft through the winch. The angle transmission box 7 is input to the shaft 5, and then the clutch 10 is en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com