heat sink

A technology for radiators and heat sinks, which is applied in indirect heat exchangers, heat exchange equipment, electric solid devices, etc., and can solve the problem of insufficient return characteristics of liquid-phase working fluid, reduced heat transfer characteristics of radiator heat pipe groups, and cooling of heat sinks. Efficiency reduction and other problems, to achieve the effect of excellent reflow characteristics, excellent cooling performance, and increased heat absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

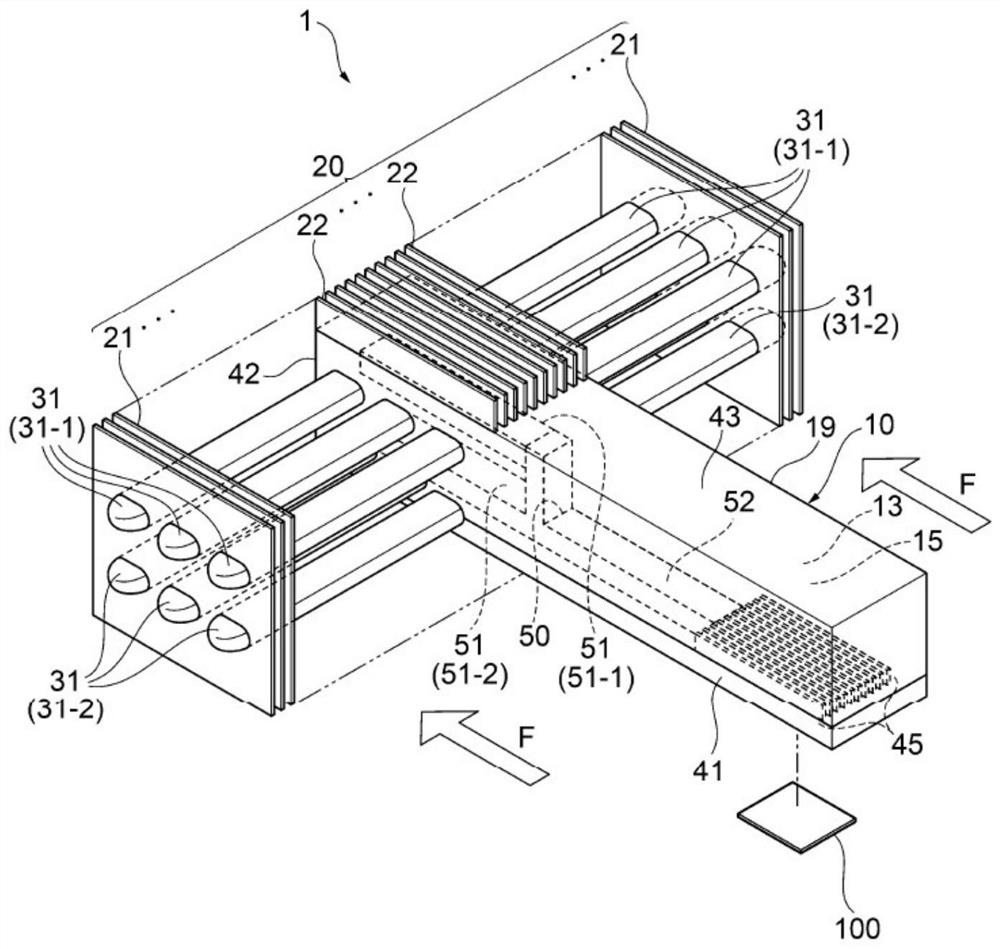

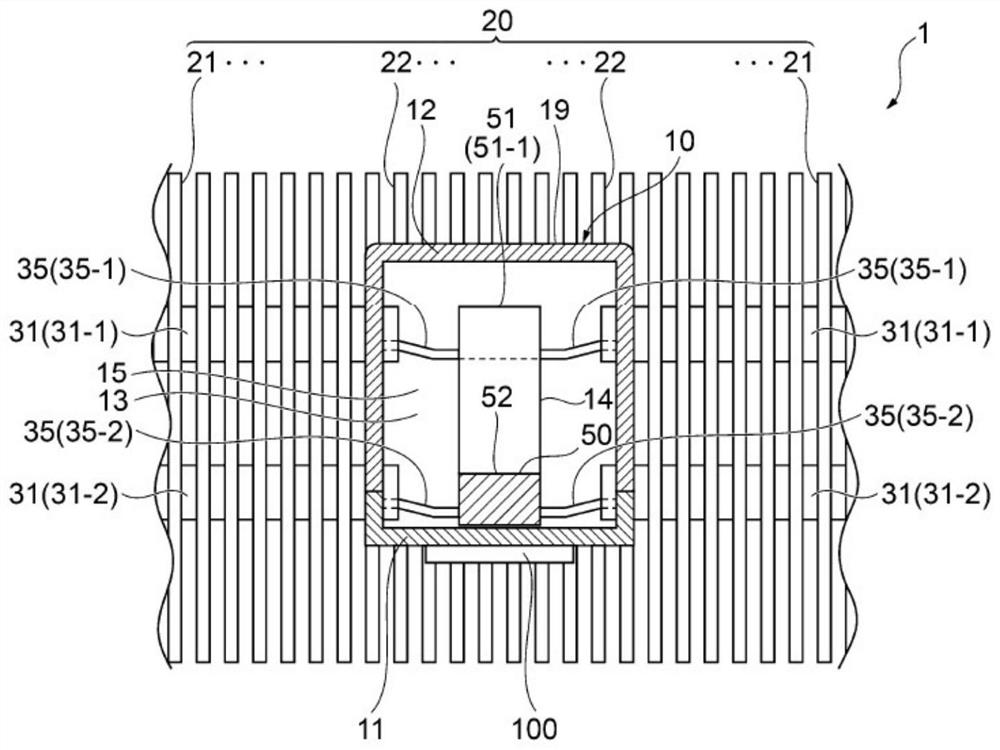

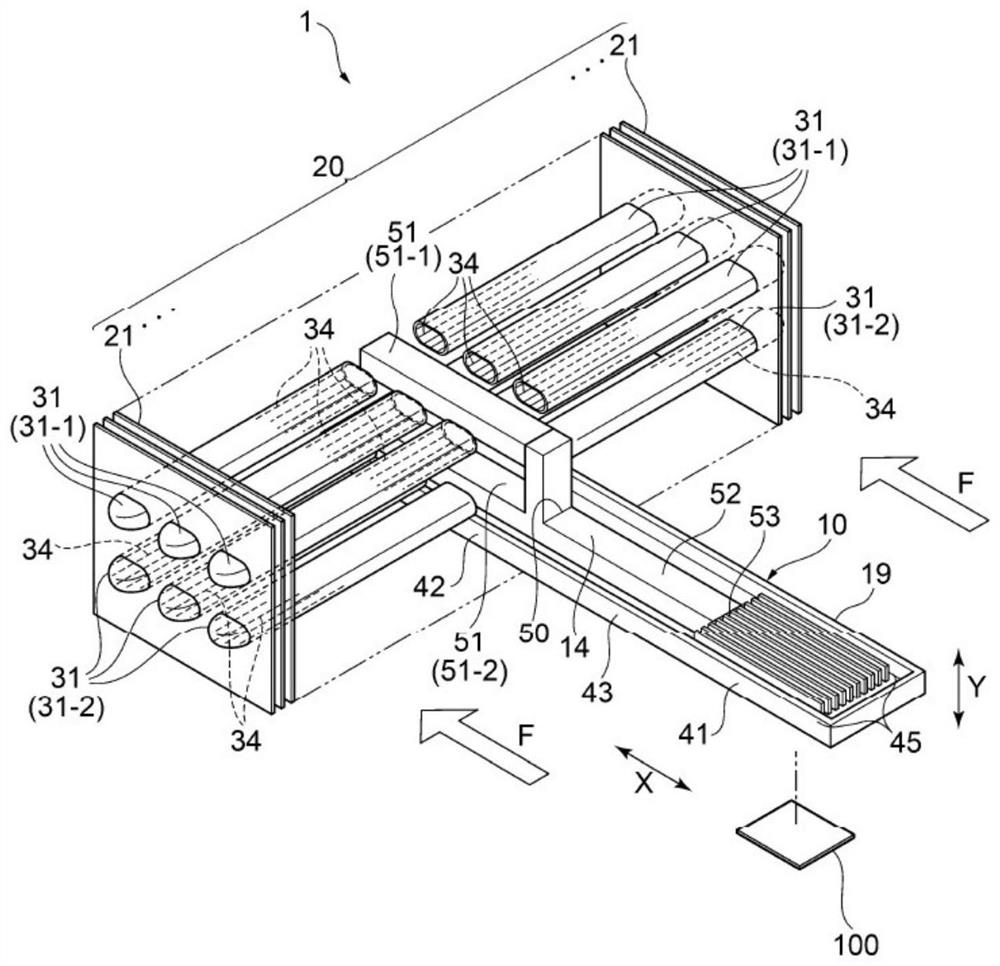

[0041]Hereinafter, the heat sink according to the embodiment of the present invention will be described with reference to the drawings.figure 1 It is an external perspective view explaining the schematic structure of the heat sink according to the embodiment of the present invention.figure 2 It is a front cross-sectional view illustrating a schematic structure inside the heat sink according to the embodiment of the present invention.image 3 It is a perspective view explaining a schematic structure inside the heat sink according to the embodiment of the present invention.Figure 4 It is a plan sectional view explaining a schematic structure inside the heat sink according to the embodiment of the present invention.

[0042]Such asfigure 1 As shown, the radiator 1 involved in the embodiment of the present invention includes: a heat transfer member 10 having a heat receiving portion 41 thermally connected to a heating element 100; a tube body 31 connected to a heat dissipation portion 42 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com