Patents

Literature

34results about How to "Flow obstruction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

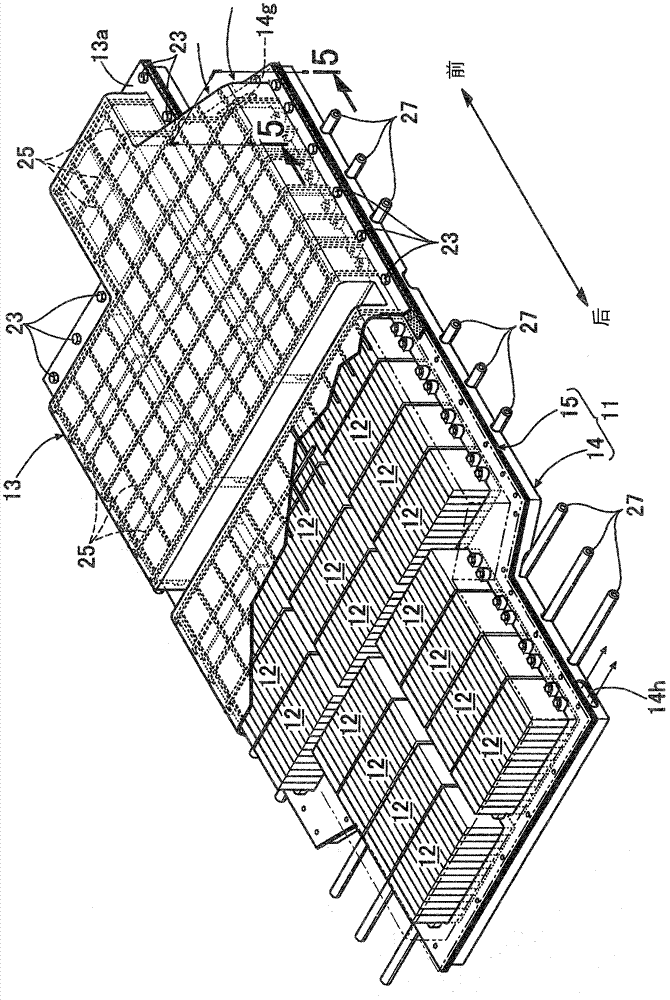

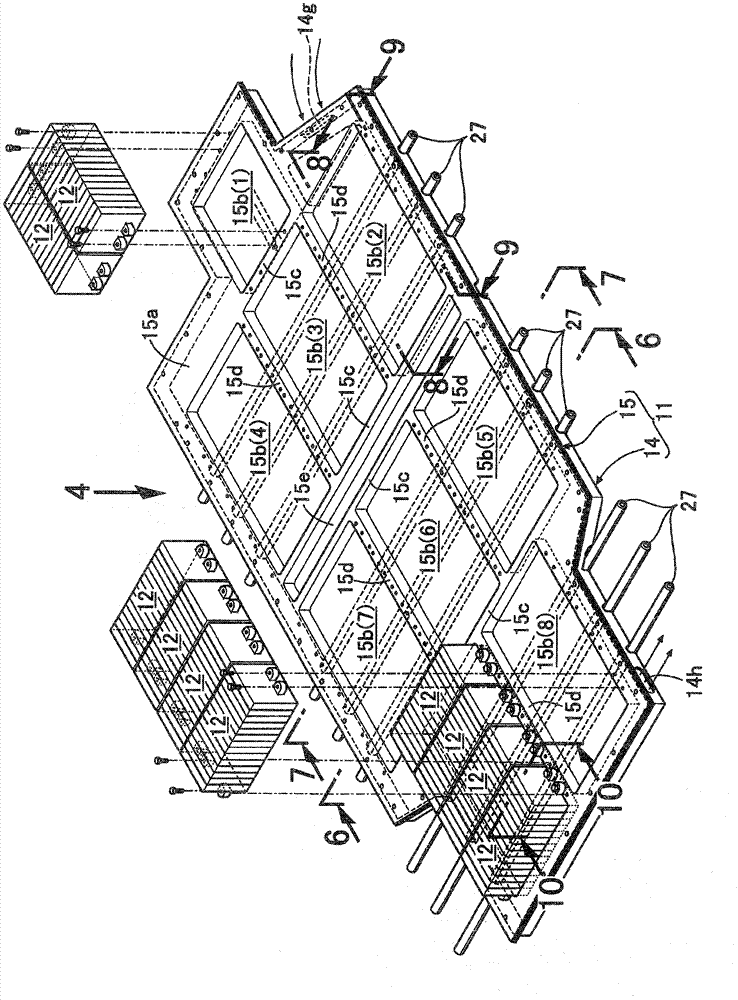

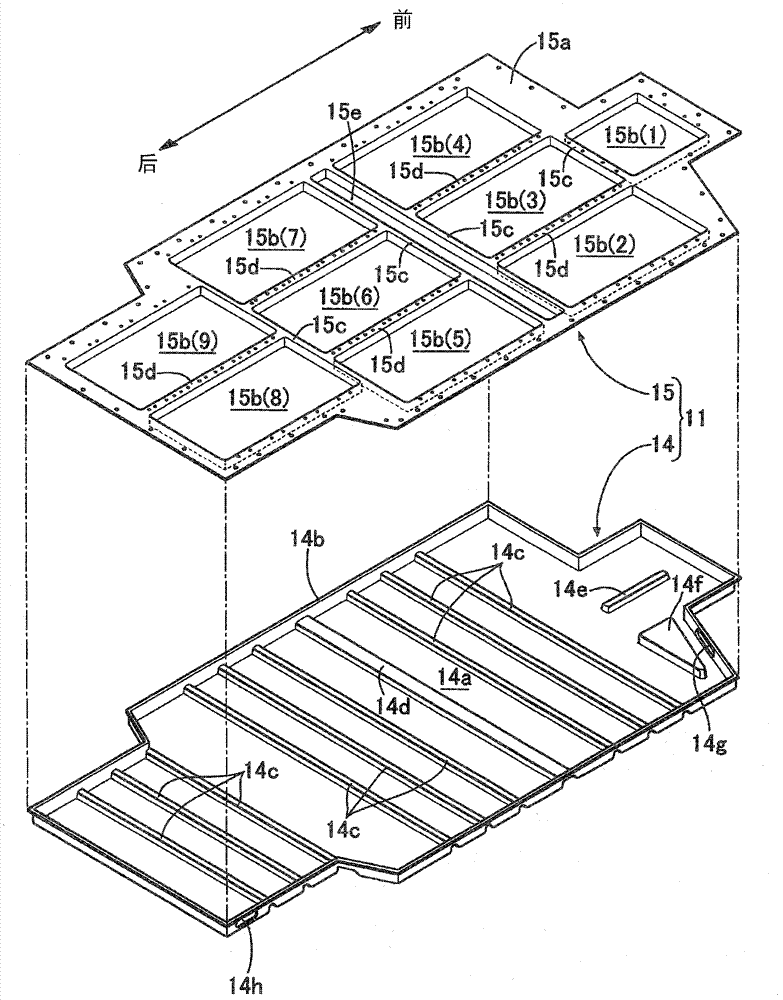

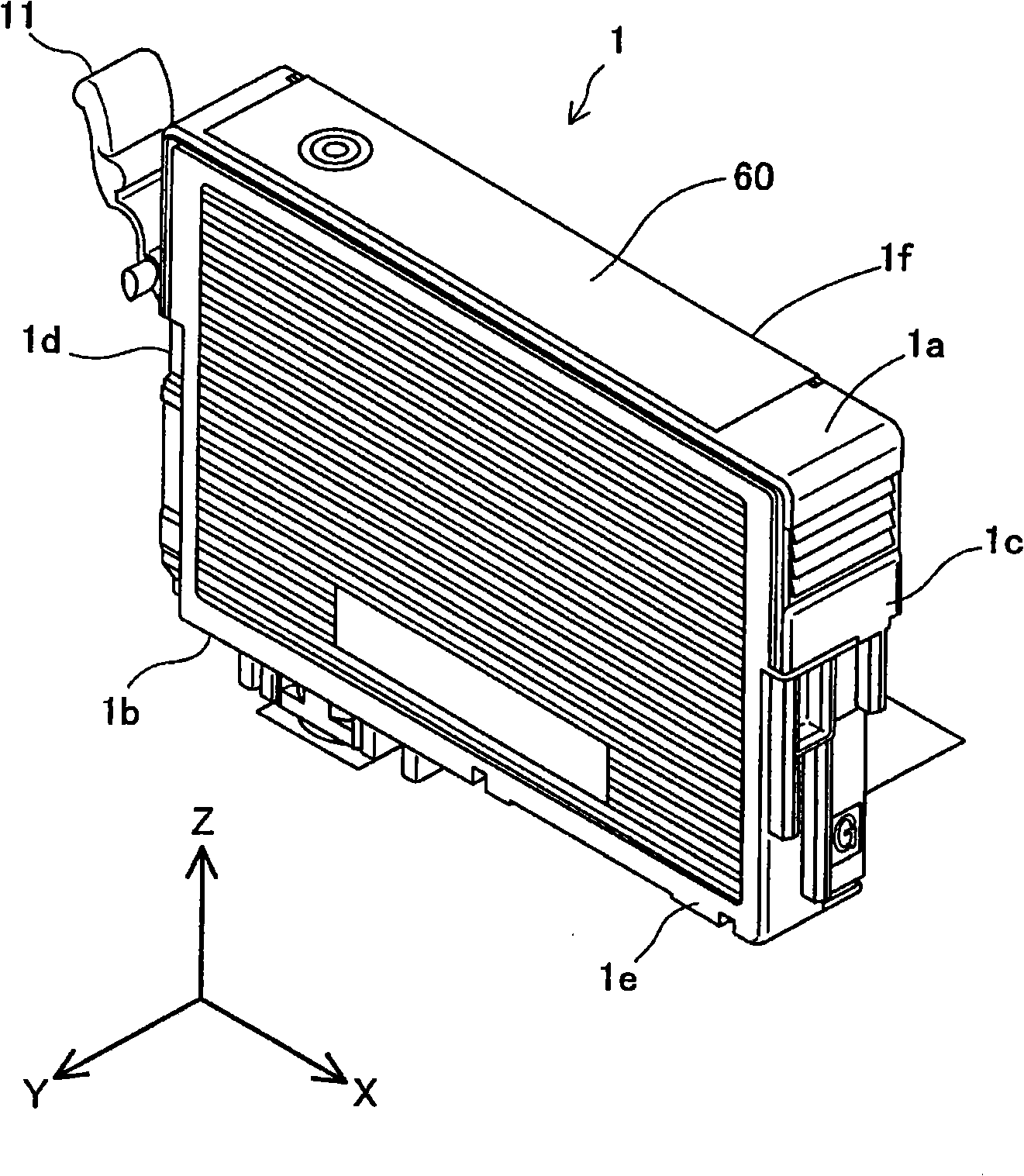

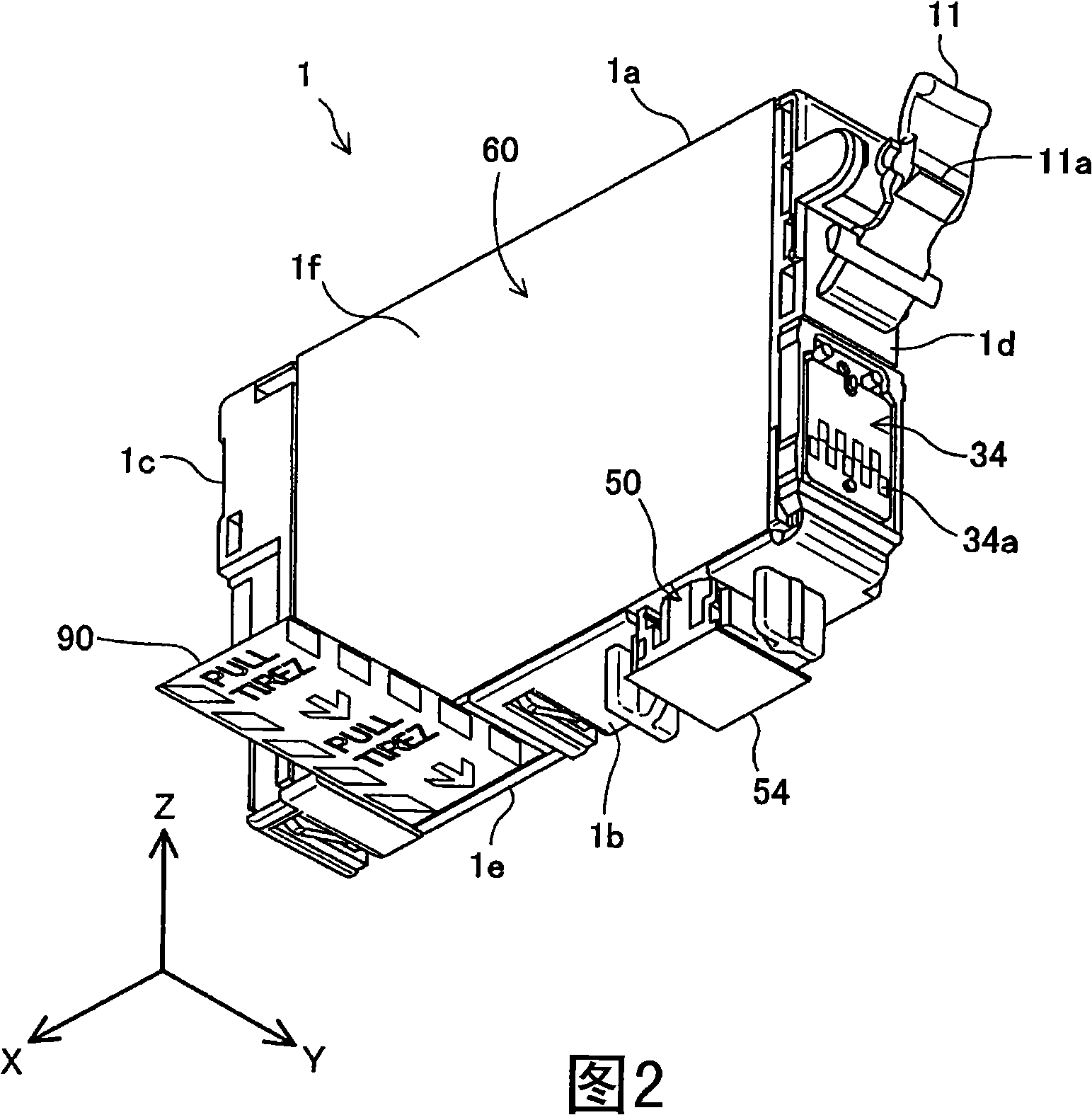

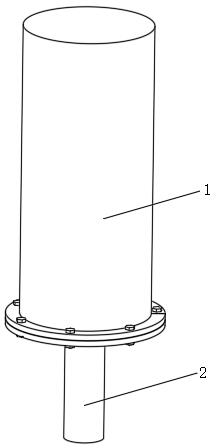

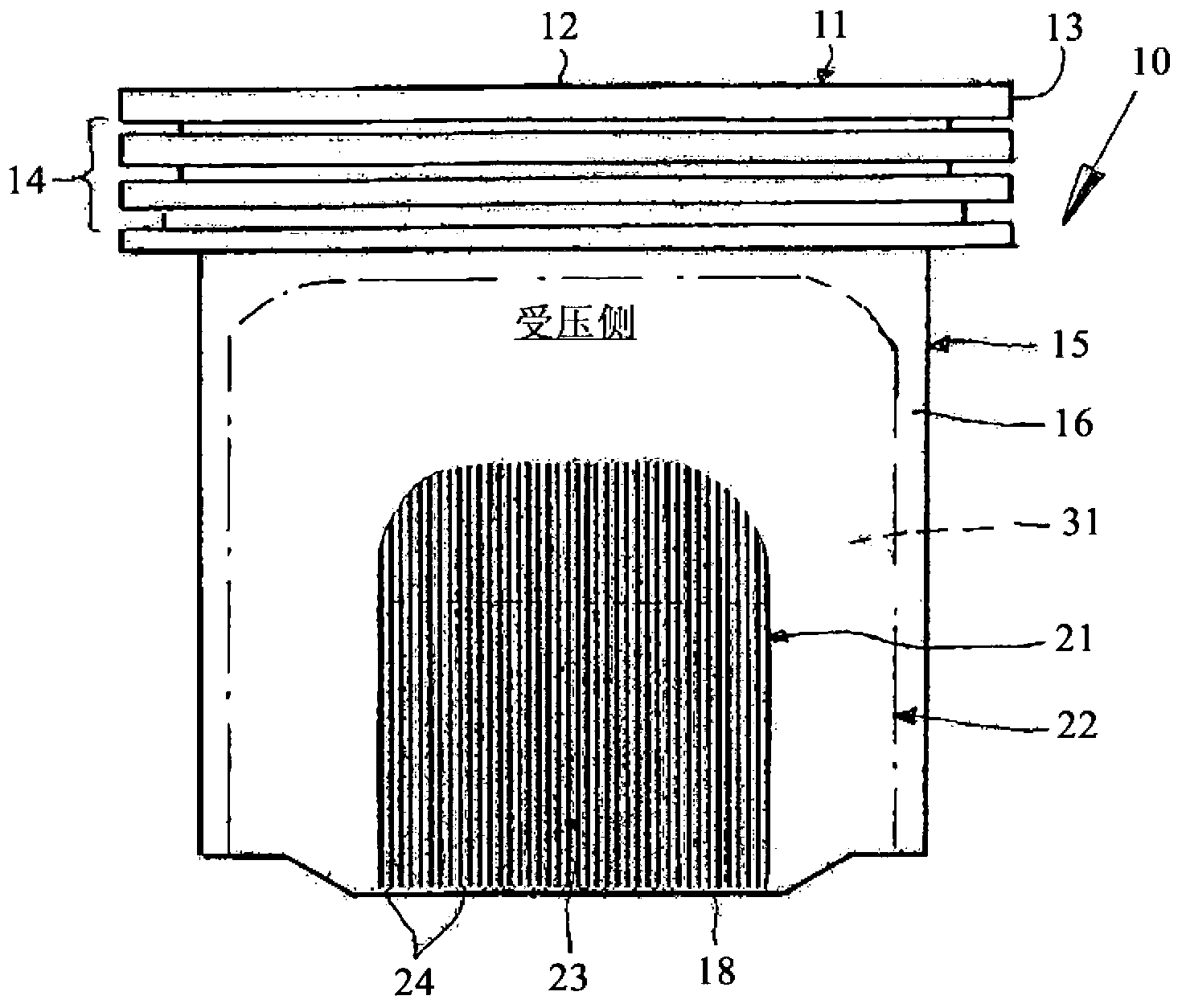

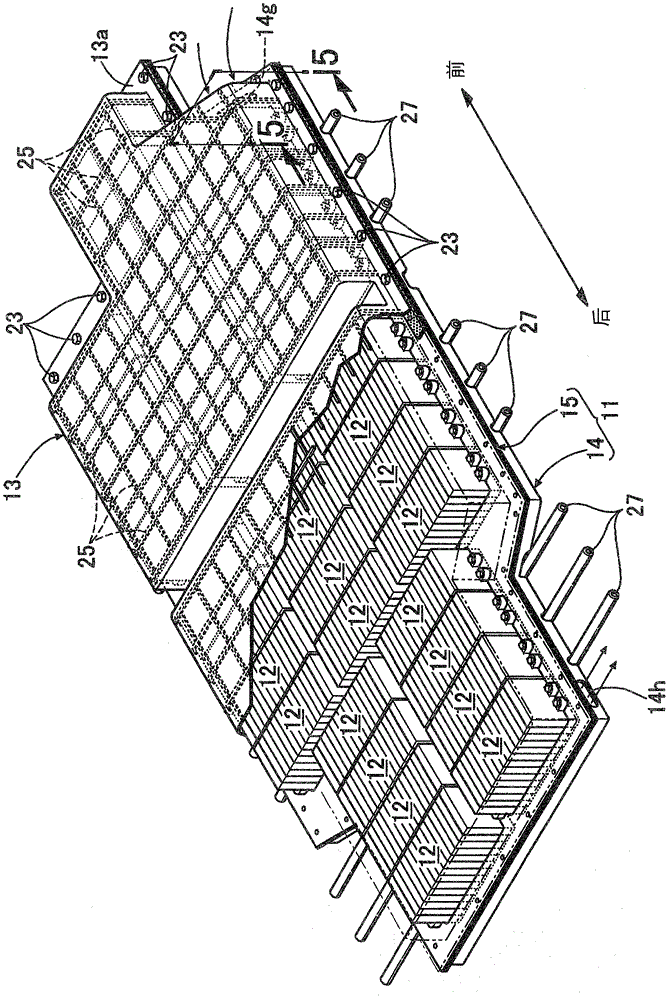

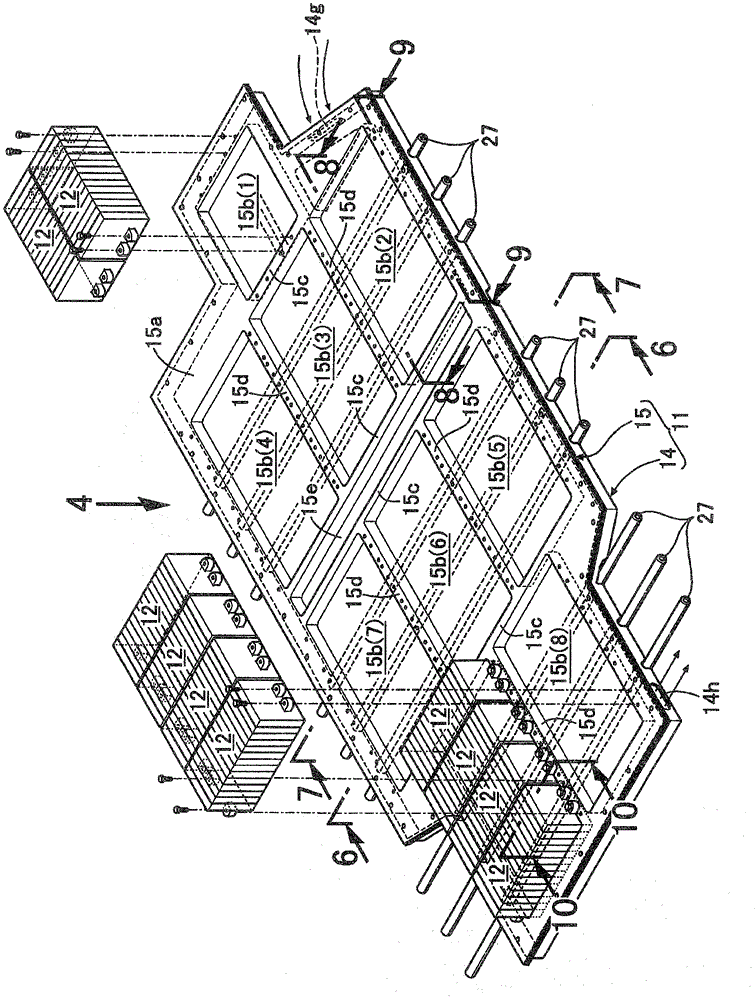

Power supply apparatus for vehicle

ActiveCN102820439AGuaranteed Cooling PerformanceGuaranteed rigidityCell temperature controlElectric propulsion mountingEngineeringCoolant flow

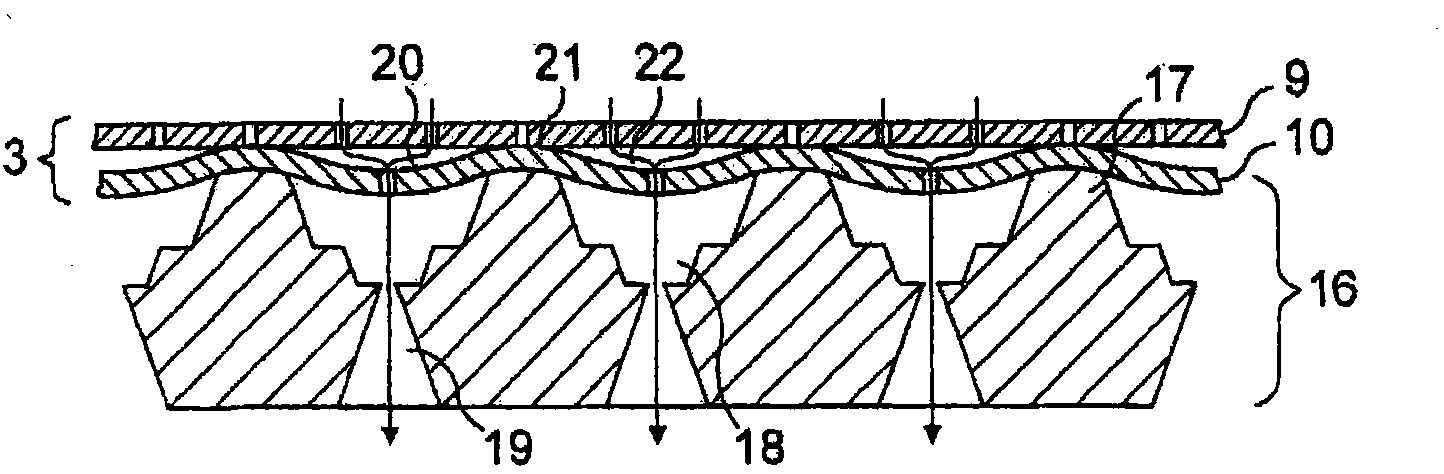

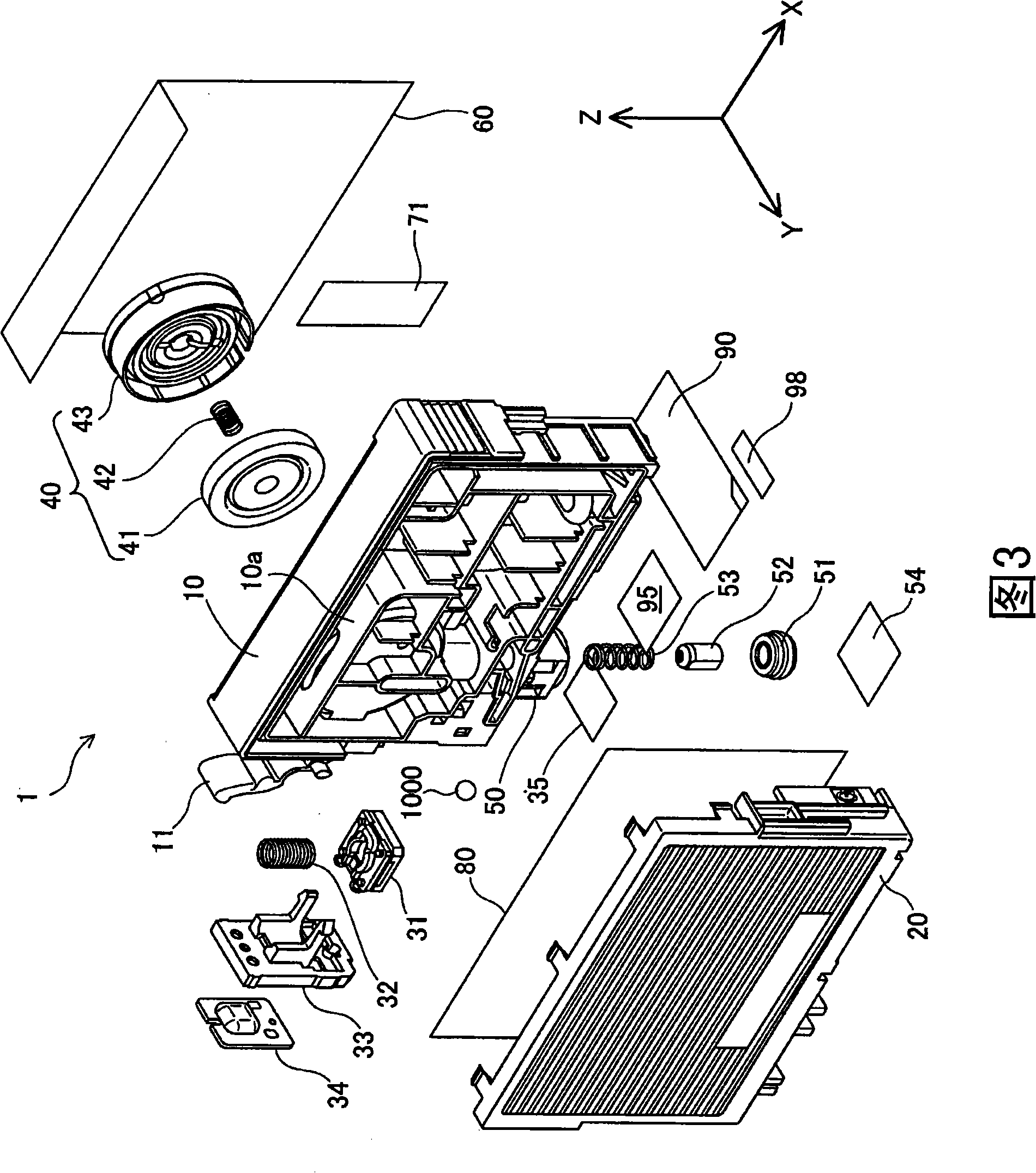

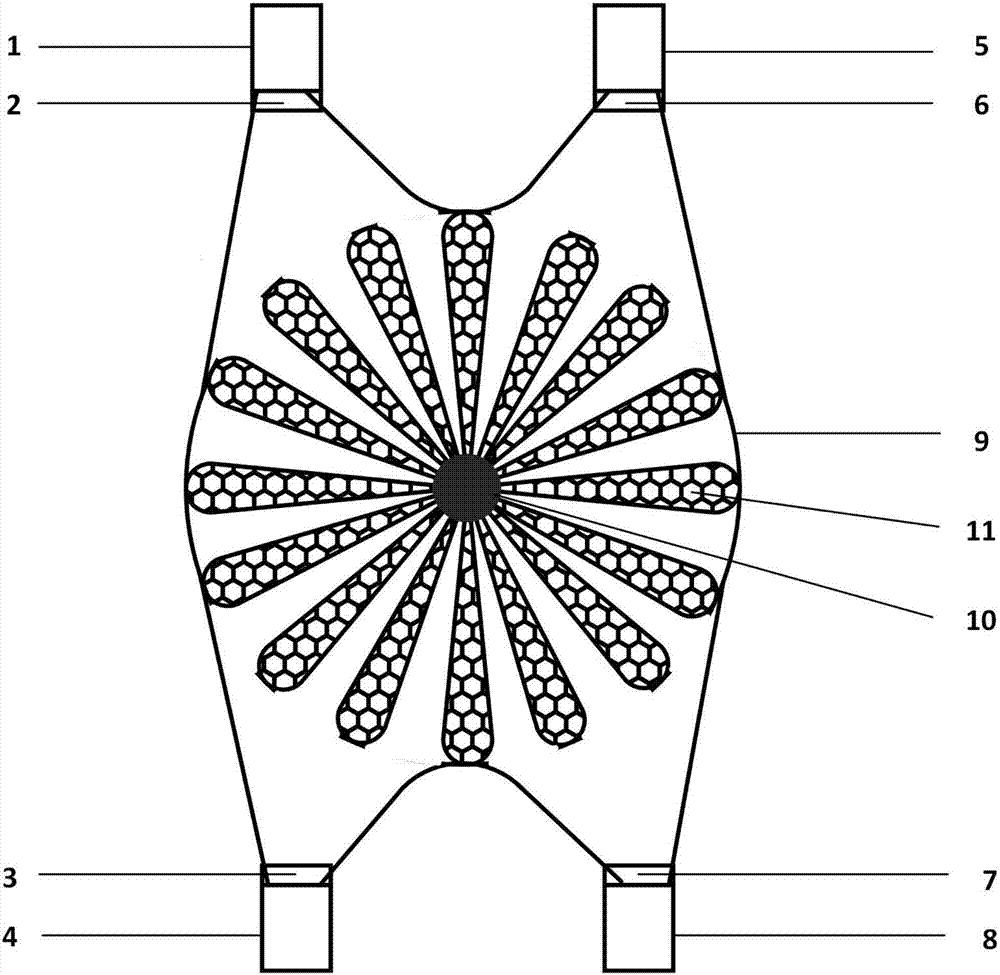

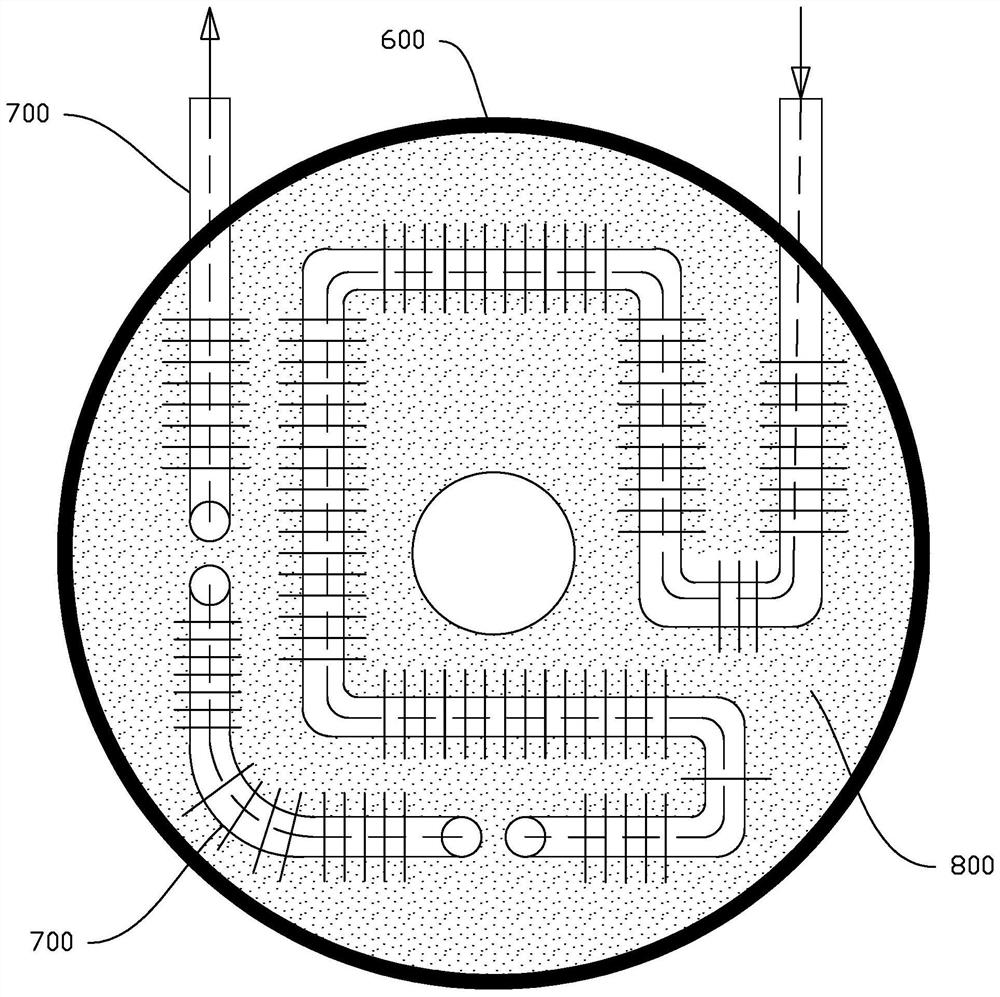

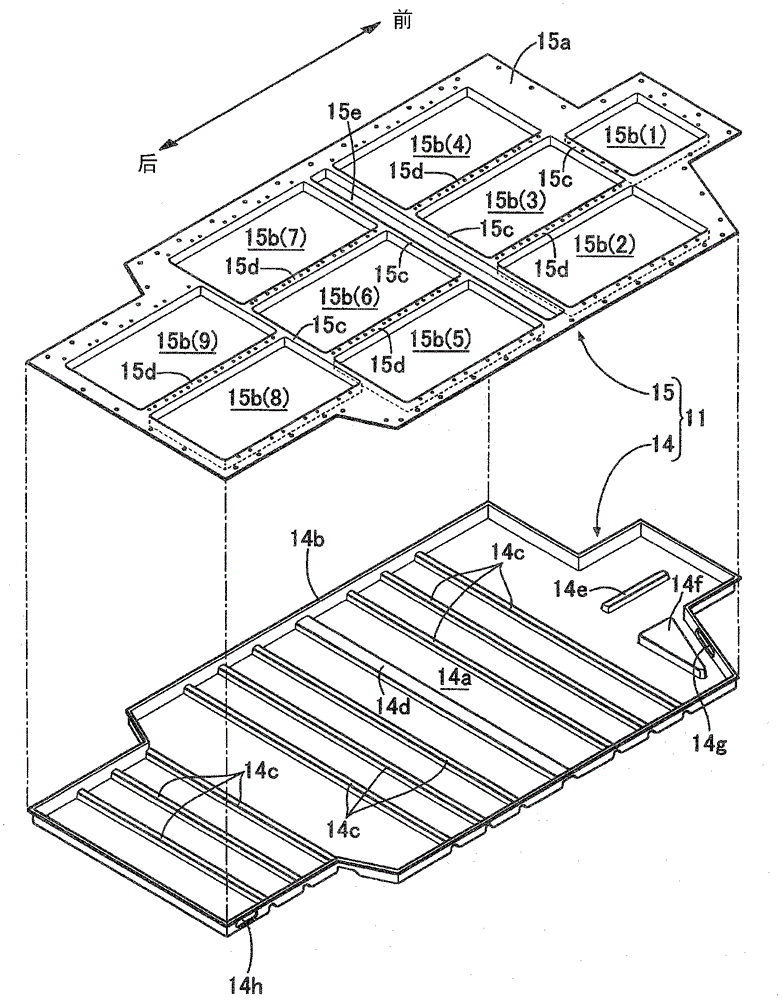

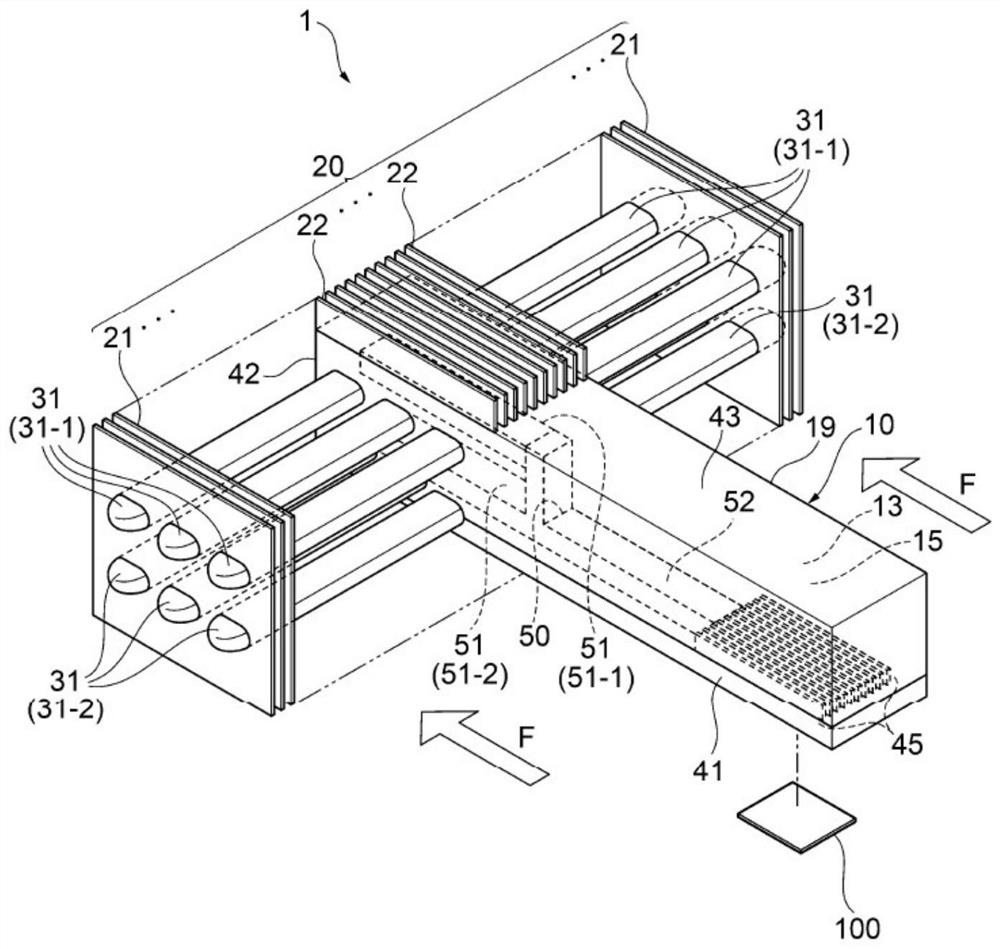

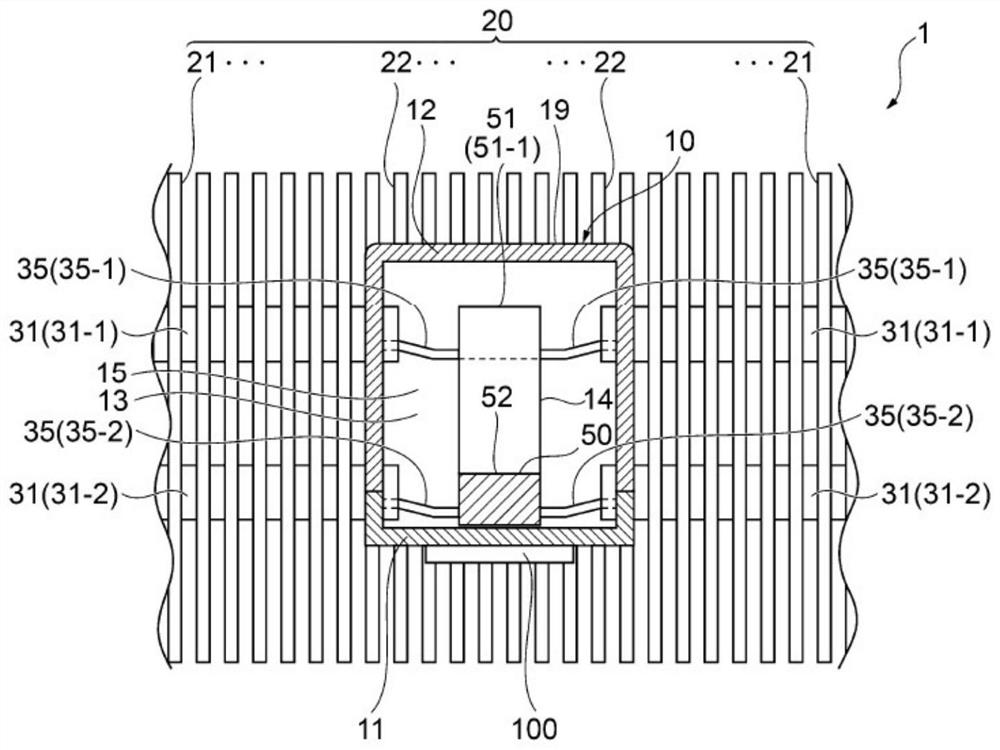

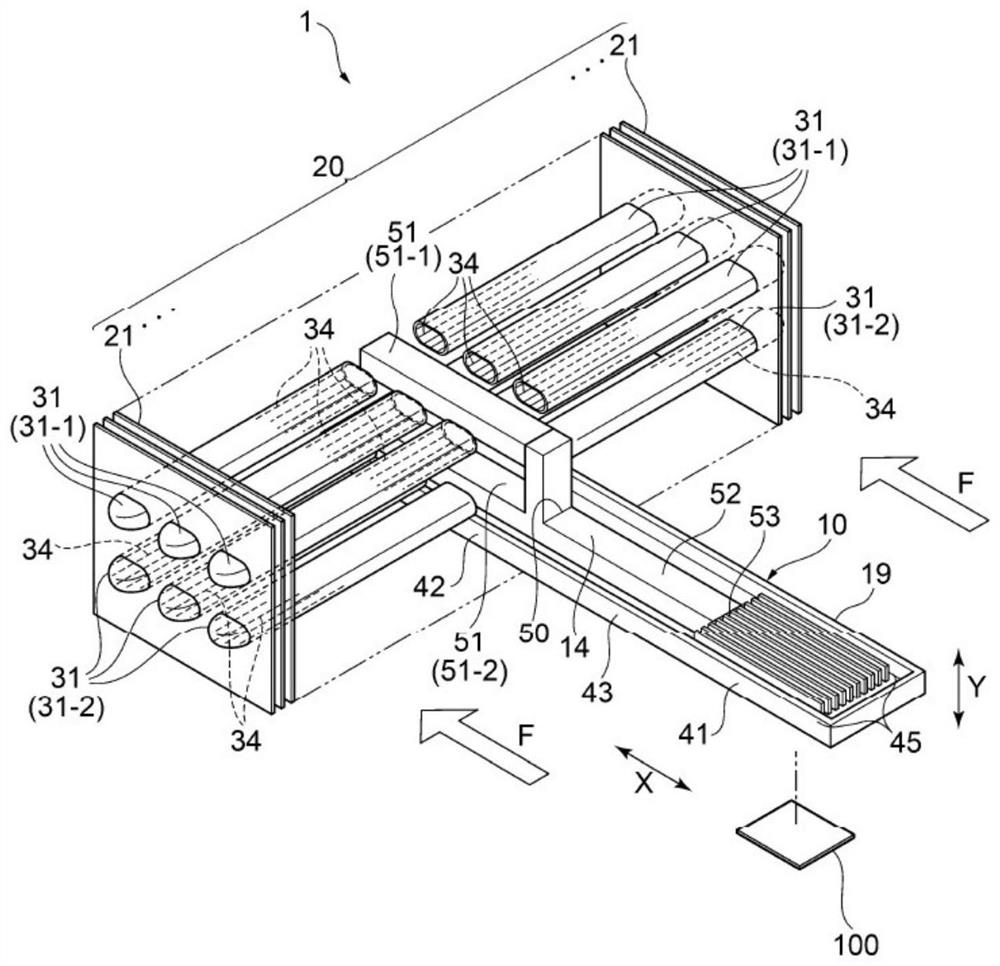

The invention provides a power supply apparatus for a vehicle, wherein the rigidity and the cooling performance of the support plate which supports and cools the battery modules. The support plate 11 supports the battery modules and includes a first plate (15) and a second plate (14). The first plate (15) thermally contacts bottom surfaces of the battery modules. The second plate (14) is placed on a bottom surface of the first plate to define cooling spaces where a coolant flows. The first reinforcing projections (14c, 14d) project into the cooling spaces and extend in in a flow direction of the coolant. The plurality of second reinforcing projections (15d) is provided on a top surface of the first plate (15) and extending in a direction crossing the flow direction of the coolant. Rigidity against bending of the support plate in two directions can be secured by the first reinforcing projections and the second reinforcing projections, and the first reinforcing projections projecting into the cooling spaces extend in the flow direction of the coolant, and the second reinforcing projections project out of the cooling spaces, and the second reinforcing projections (15d) project out of the cooling spaces. Therefore the first and second reinforcing projections do not interfere with the flow of the coolant, thereby securing the cooling performance.

Owner:HONDA MOTOR CO LTD

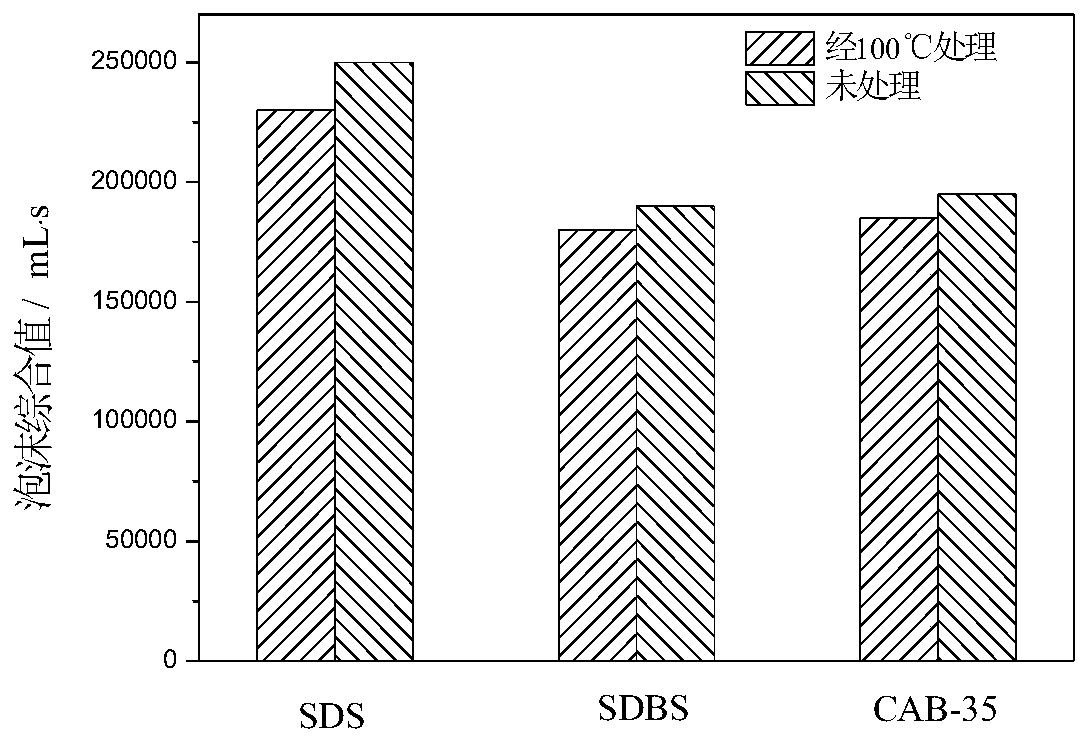

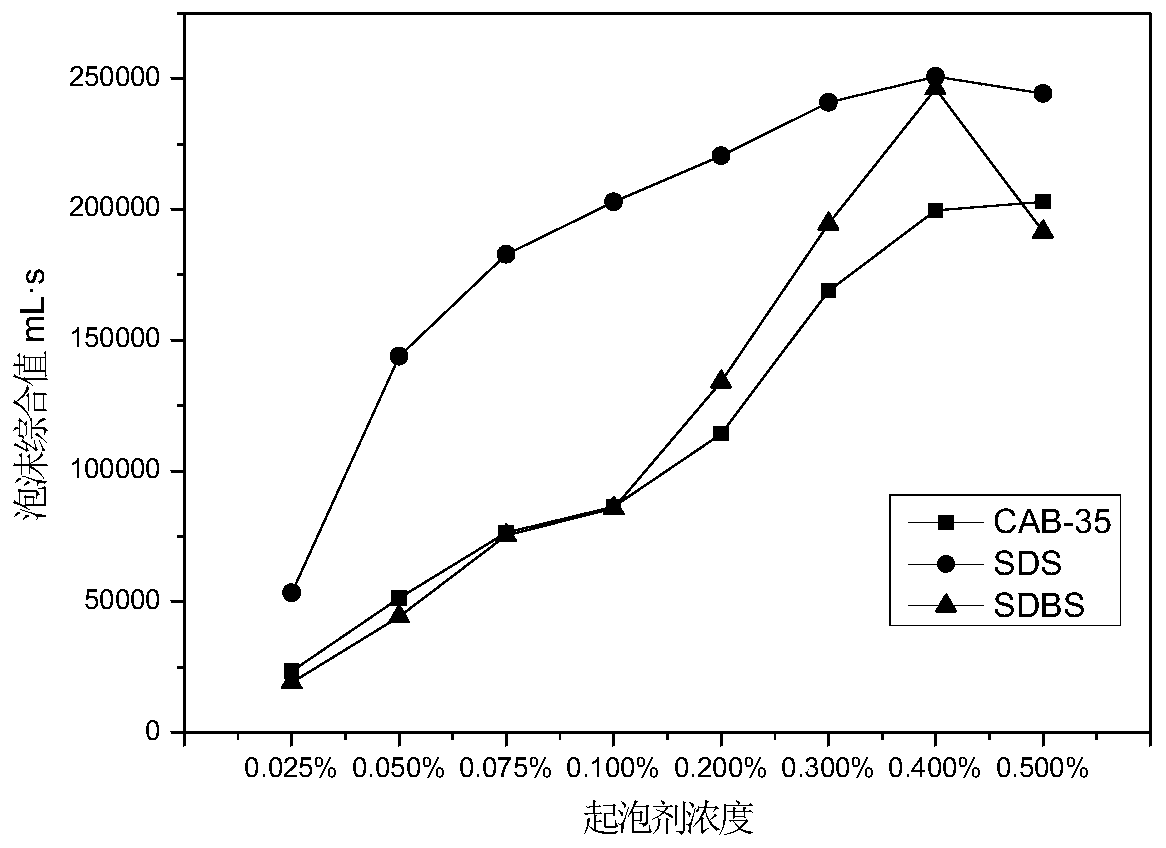

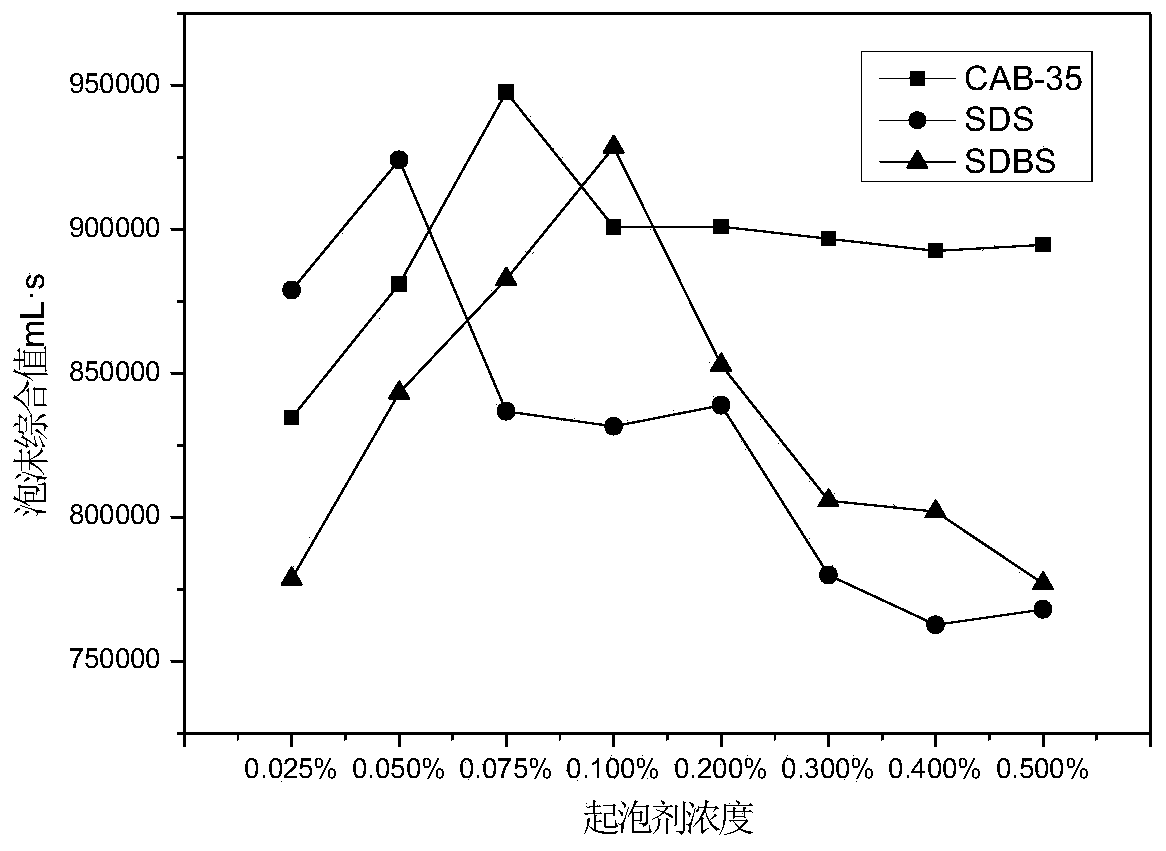

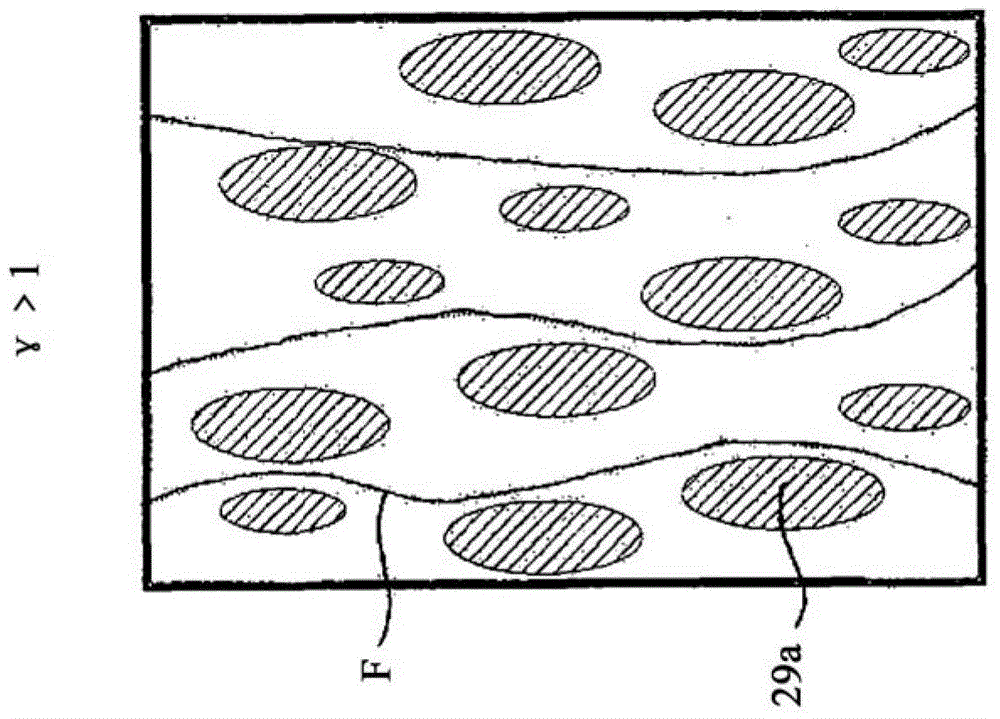

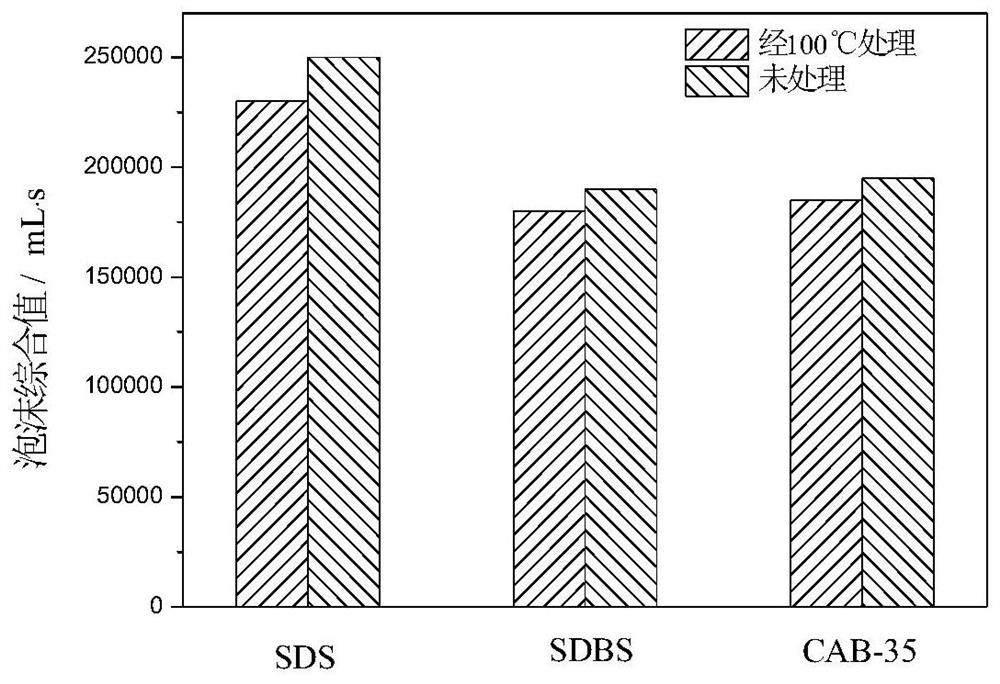

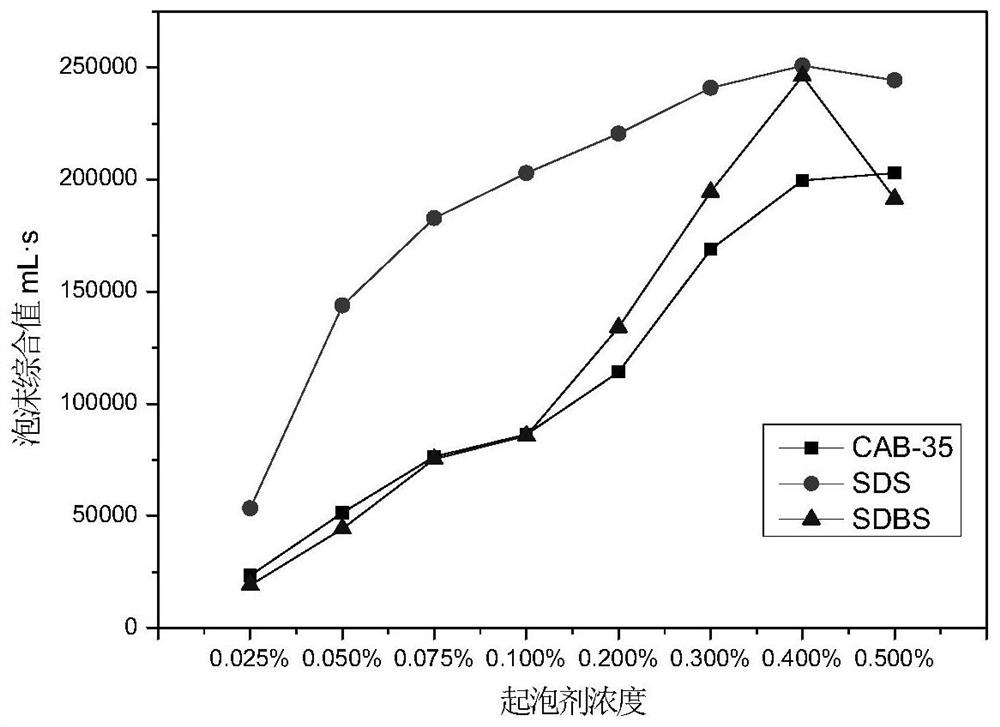

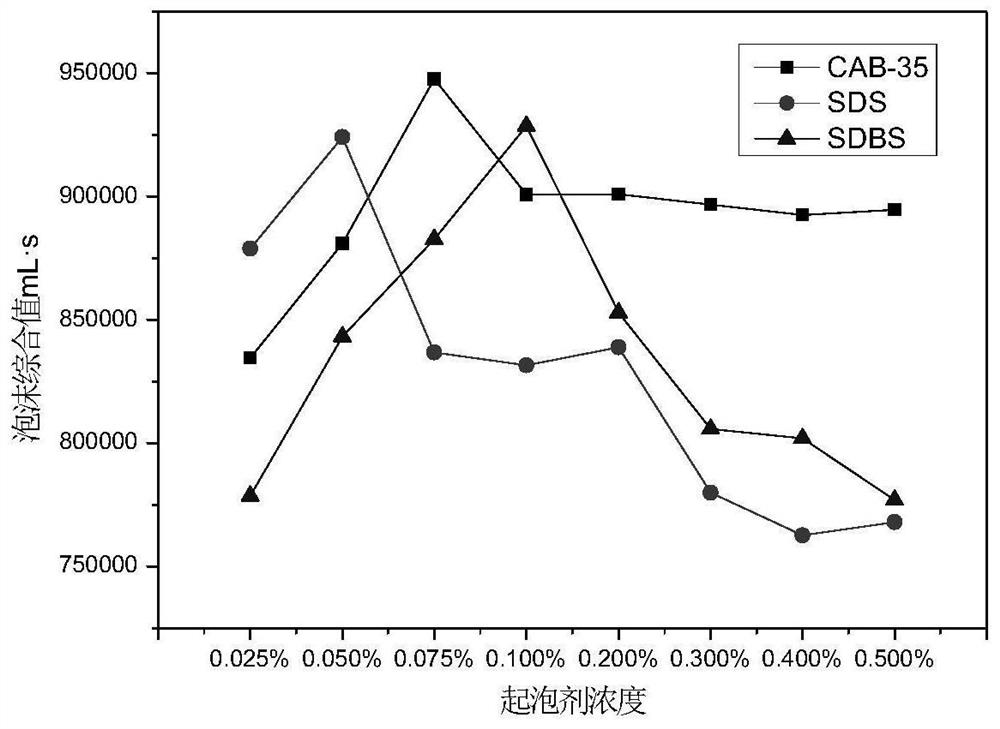

Temperature-resistant foam gel as well as preparation method and application thereof

The invention discloses a temperature-resistant foam gel as well as a preparation method and application thereof. The temperature-resistant foam gel comprises the following components in percentage bymass: 0.3% of a polymer; 0.15%-0.35% of a cross-linking agent; 0.05%-0.15% of a foaming agent; and the balance water; the cross-linking agent is a cross-linking agent A or a mixture of the cross-linking agent A and a cross-linking agent B, and the cross-linking agent A is resorcinol; and the cross-linking agent B is formaldehyde. It is found by observing microstructures of water-based foam, polymer solution foam and the foam gel by using a microscope and a scanning electron microscope that common foam and polymer cannot keep stable for a long time due to flowing of a liquid film at normal temperature, and the liquid film of the foam gel forms a reticular gel structure, so that the viscosity and strength of the liquid film are enhanced, the flowing of the liquid film is hindered, and the foam gel has better stability at high temperature. It is shown by low-permeability fracture type rock core plugging experiment, the foam gel system can form effective plugging in rock cores, has a goodgas breakthrough inhibition effect, and has a wide application prospect in low-permeability oil reservoir.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

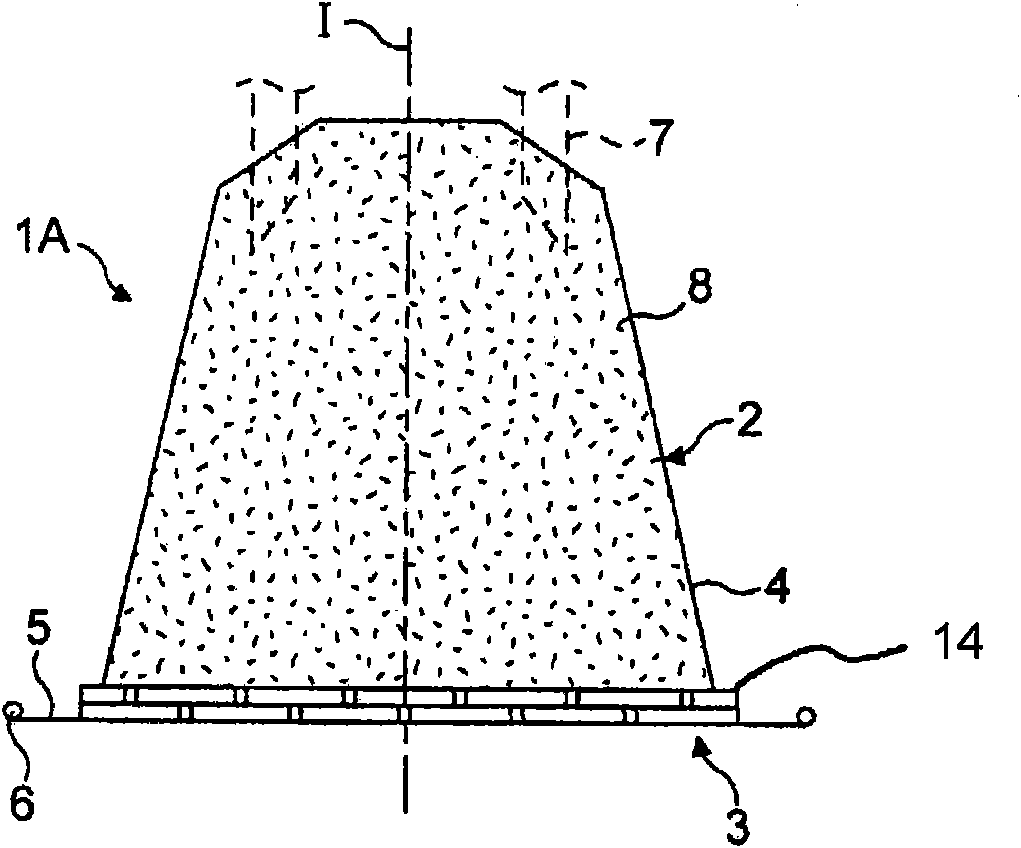

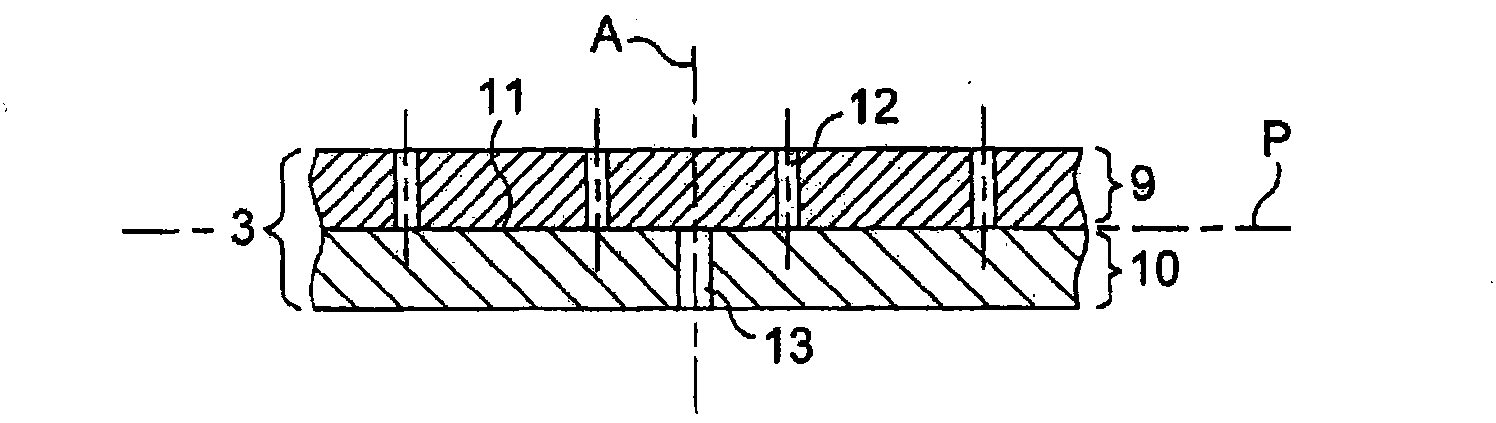

Capsule for preparation of a beverage with delaminating or breakable seal at delivery wall

InactiveCN101862122AFlow obstructionExtended freshness timeBeverage vesselsPackagingGround coffeeBiomedical engineering

A capsule for preparation of a beverage in a beverage production machine. The capsule includes a body and a delivery wall forming a chamber containing ground coffee. The delivery wall has at least one outlet, an inner layer and an outer layer forming respectively first and second layers at least partially connected together by at least one seal portion which delaminates or breaks under the pressure of coffee liquid against the seal portion. Preferably, the seal portion extends in a direction (P) which differs from the direction (A) of the outlet.

Owner:SOC DES PROD NESTLE SA

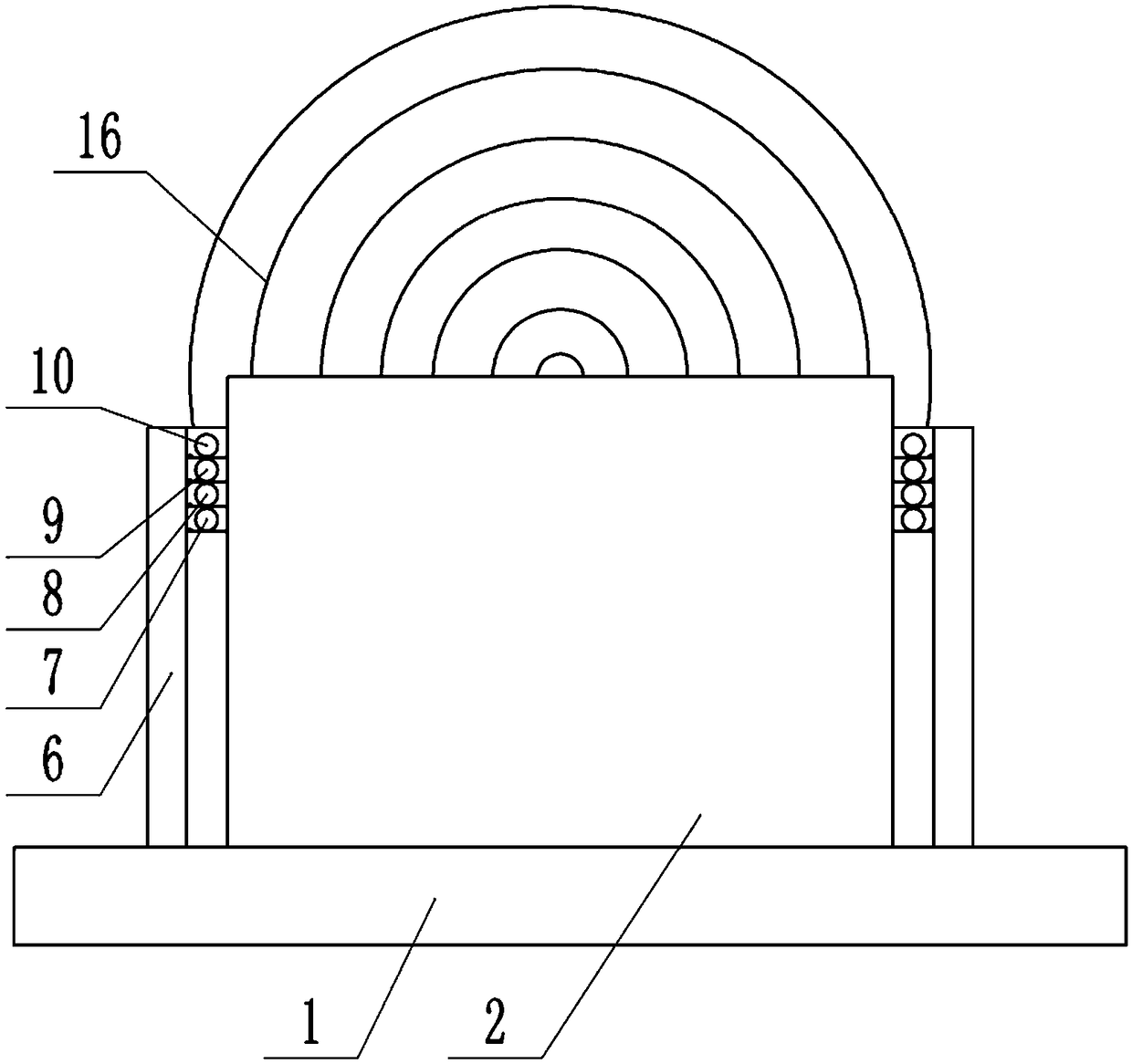

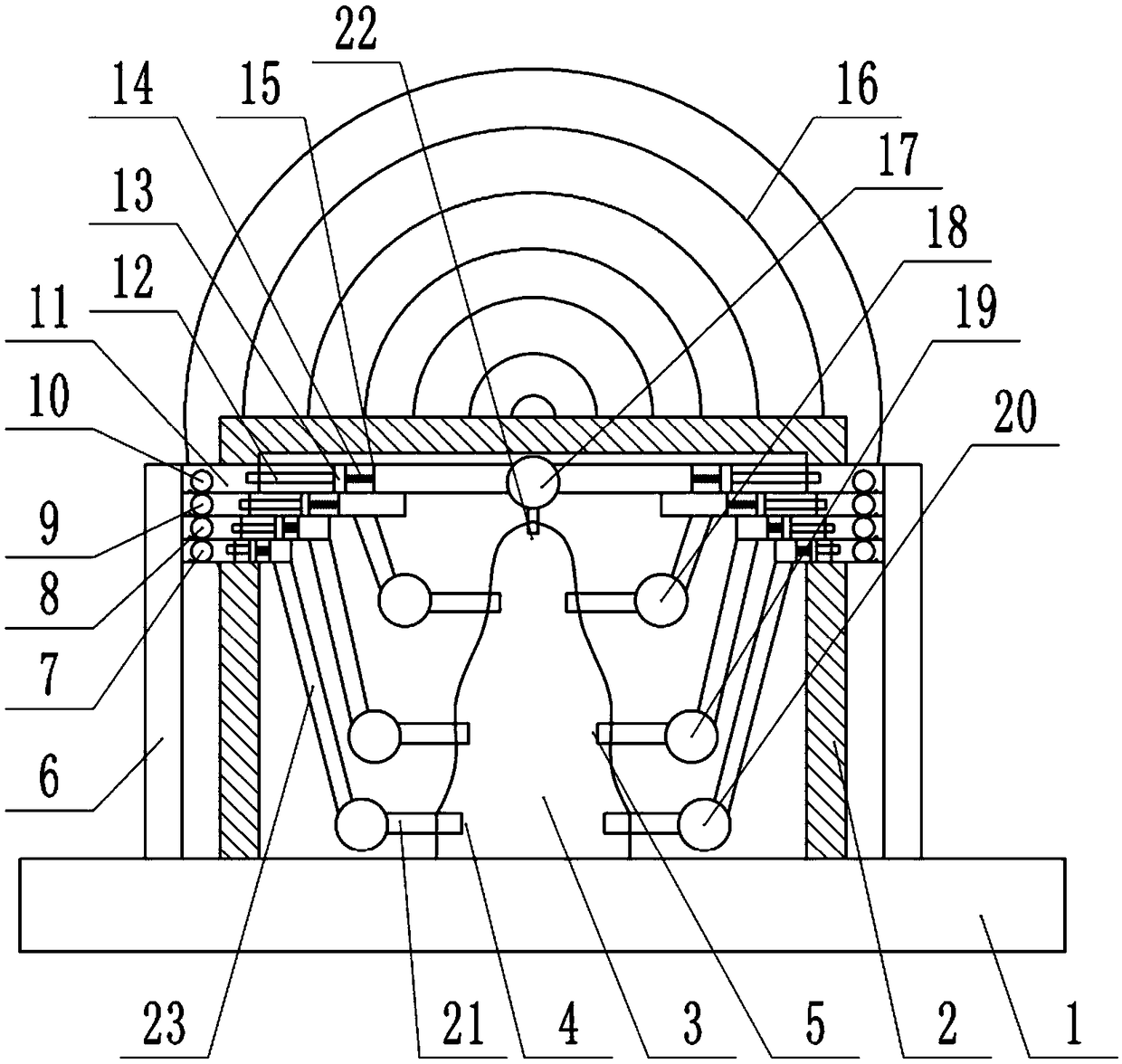

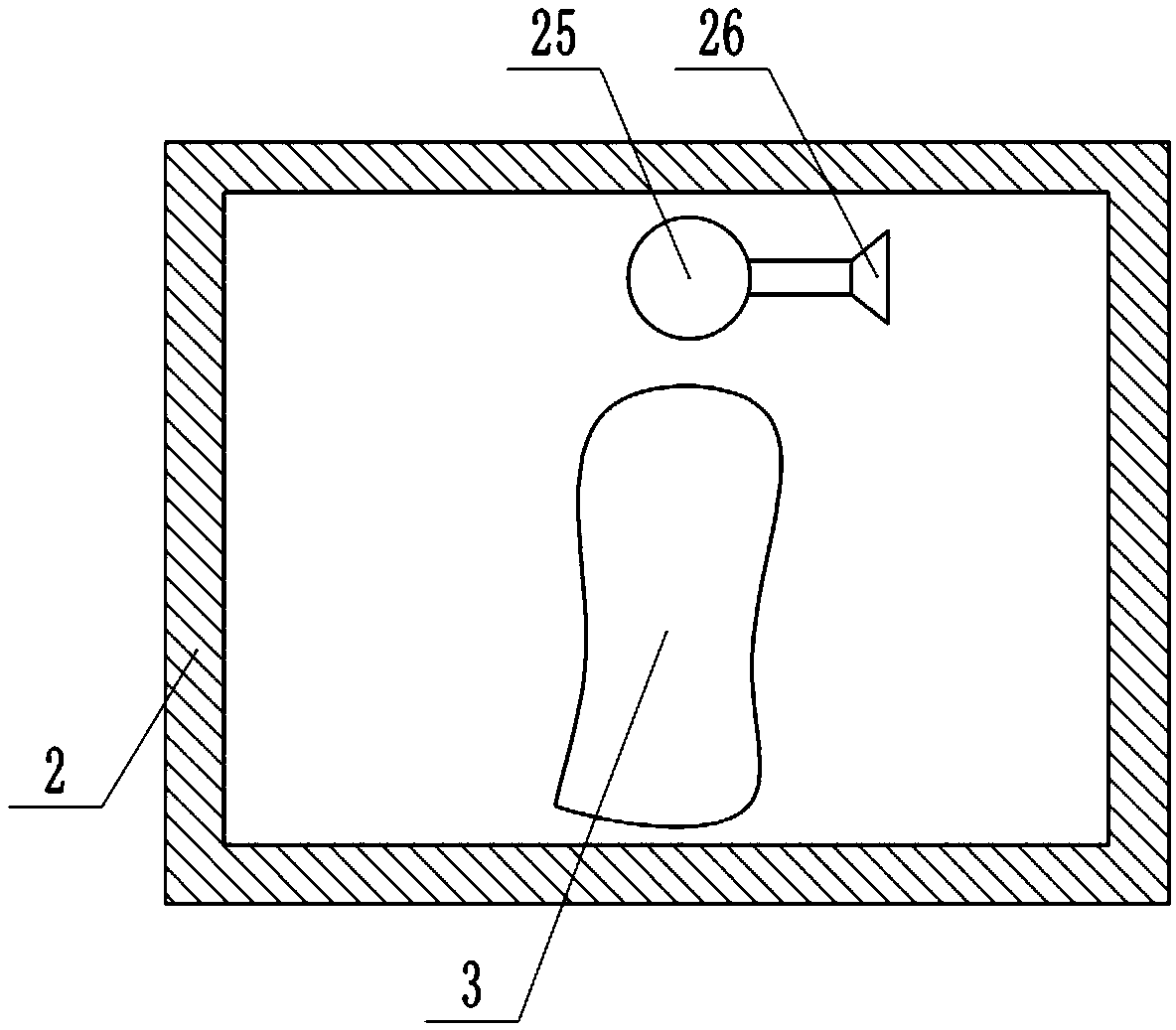

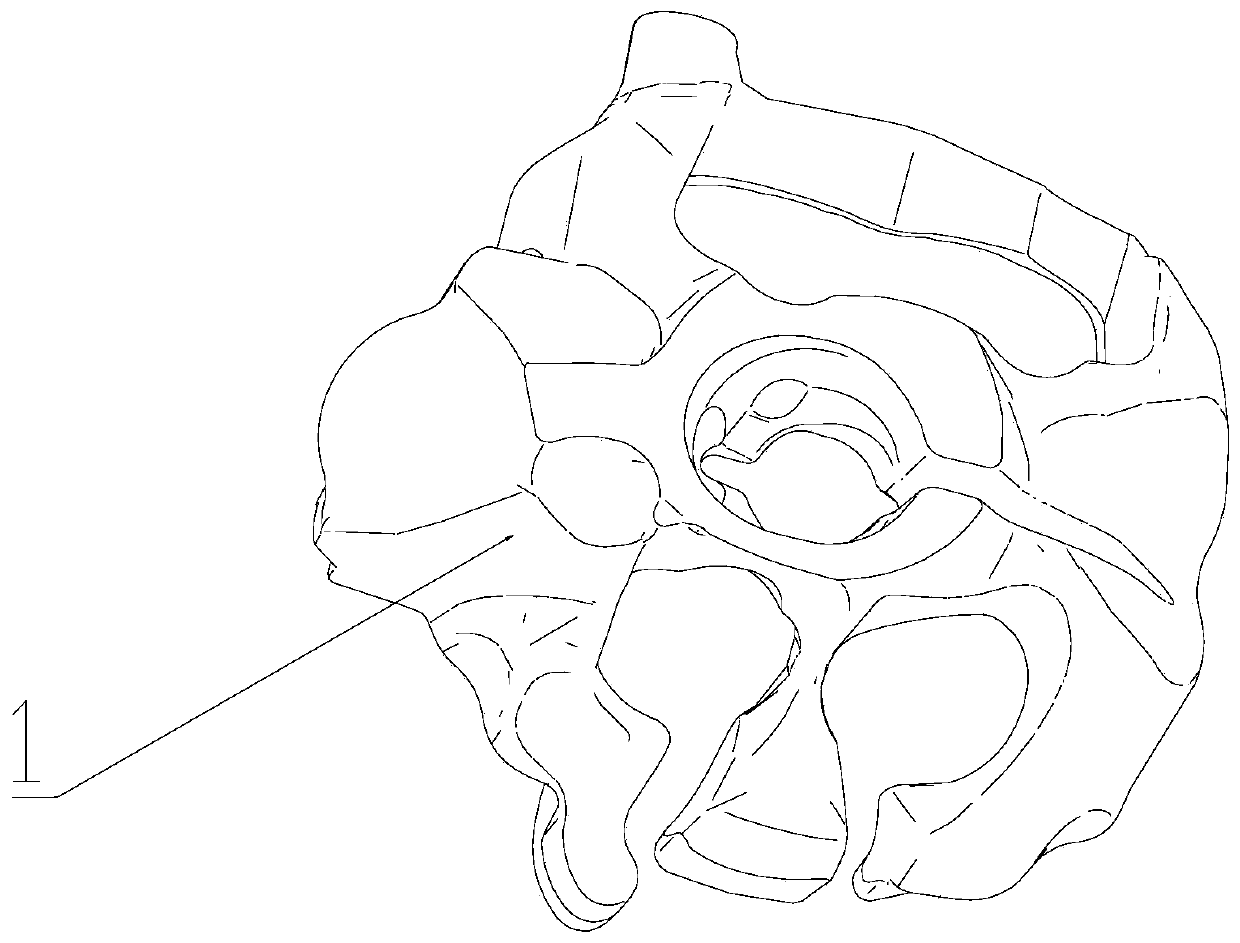

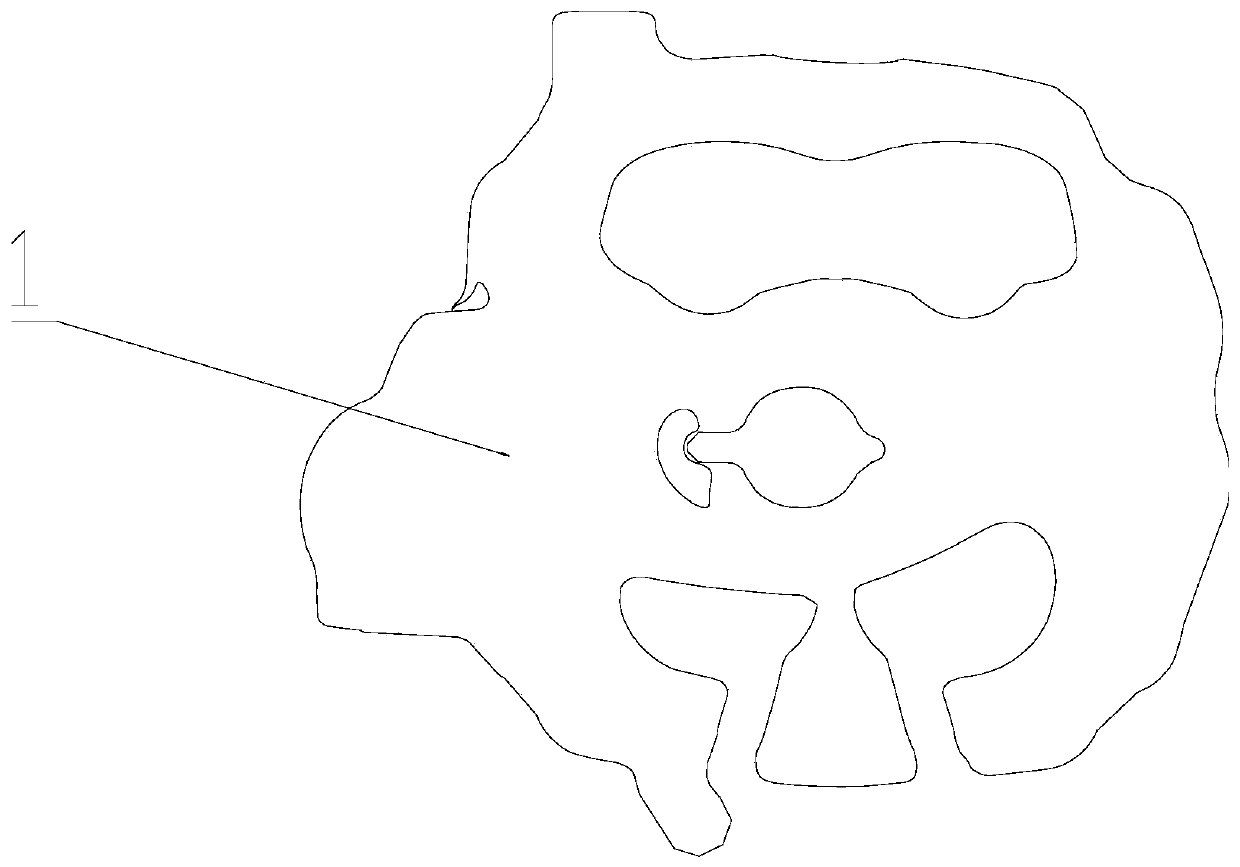

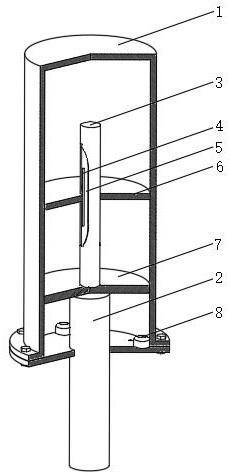

Uterine cavity gauze packing teaching model

ActiveCN109147527AAccurate gap positioningFirmly connectedEducational modelsGynecologyHeat sensitive

The invention relates to the field of medical teaching instruments and particularly relates to a uterine cavity gauze packing teaching model. The uterine cavity gauze packing teaching model comprisesa base; a transparent die body is arranged on the base; reversible heat-sensitive achromatic ink is applied to the die body; the die body is internally provided with the uterine cavity; and a heater is arranged on the base. In the scheme, a student can observe the specific structure and the construction of the uterine cavity through the teaching model while a teacher makes an explanation; and whenthe student simulates packing of the uterine cavity, the model can shield the sight of the student, and the student is ensured to judge whether gauze packing is corrected or not through own learningexperience.

Owner:THE FIRST AFFILIATED HOSPITAL OF ARMY MEDICAL UNIV

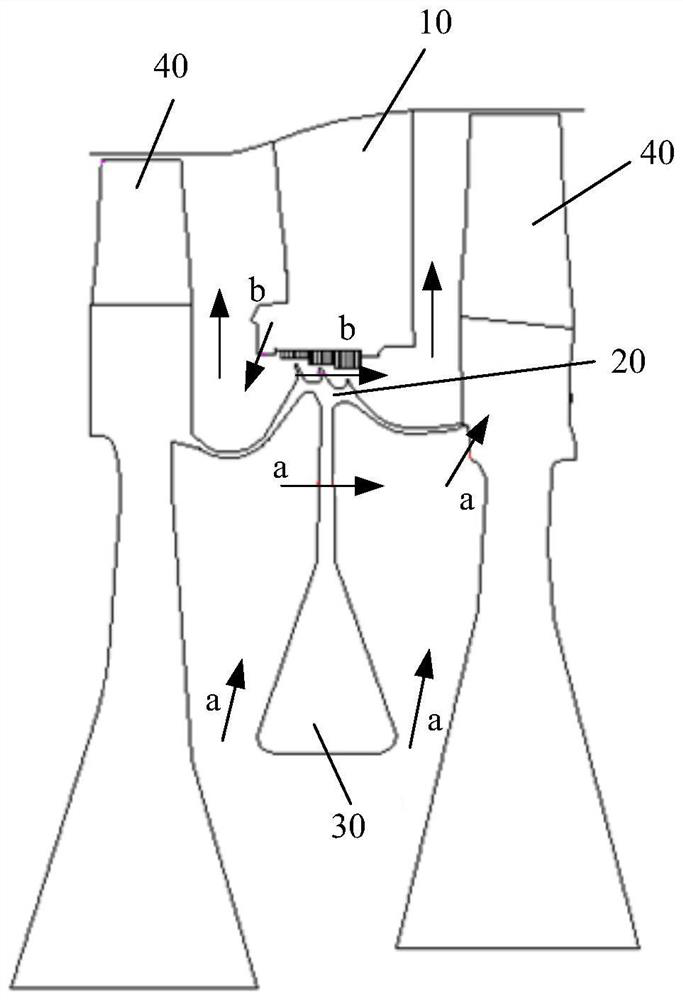

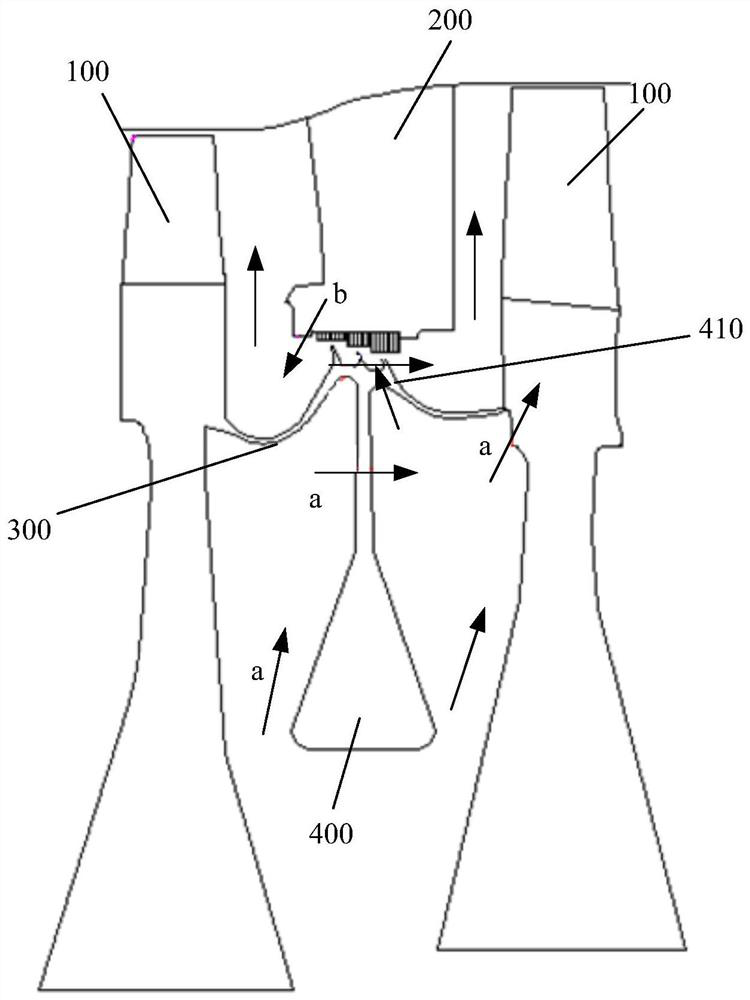

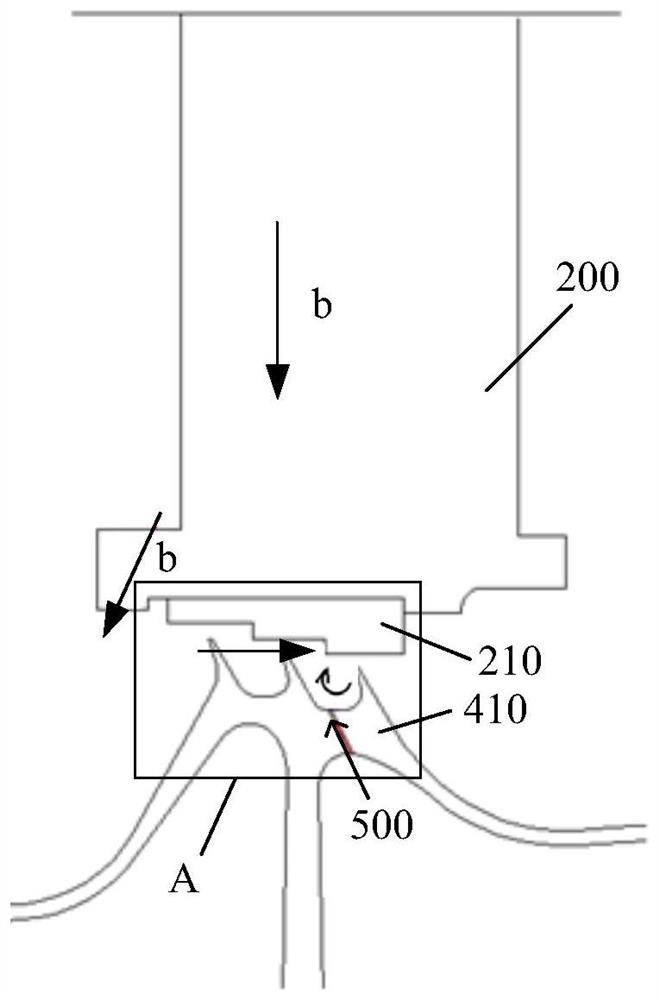

Aero-engine turbine rim sealing structure

ActiveCN112523813AHigh strengthIncrease exhaust back pressureLeakage preventionMachines/enginesJet flowTurbine

The invention provides an aero-engine turbine rim sealing structure. The aero-engine turbine rim sealing structure comprises multiple stages of rotor blades, multiple stages of stator blades, multiplestages of rotating discs and interstage sealing discs, the multiple stages of rotor blades and the corresponding multiple stages of rotating discs are vertically connected in a one-to-one correspondence mode, and the rotor blades and the stator blades are arranged at intervals. The interstage sealing discs are arranged between every two adjacent rotating discs. A labyrinth structure is arranged at the top of each interstage sealing disc and located below the corresponding stator blades, at least one first vent hole is formed between tooth parts of the labyrinth structure, part of cooling gasflows into a cavity between the tooth parts through the first vent holes. The mixed gas flows into a rear edge wheel sealing cavity of each stator blade after being mixed with sealing gas. According to the aero-engine turbine rim sealing structure, a small flow path is added to exhaust air between tooth parts of the labyrinth structure, so that radial impact jet flow is formed while the back pressure of backward flowing of front sealing airflow is improved, and the flowing of axial backward airflow of tooth tips is hindered.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

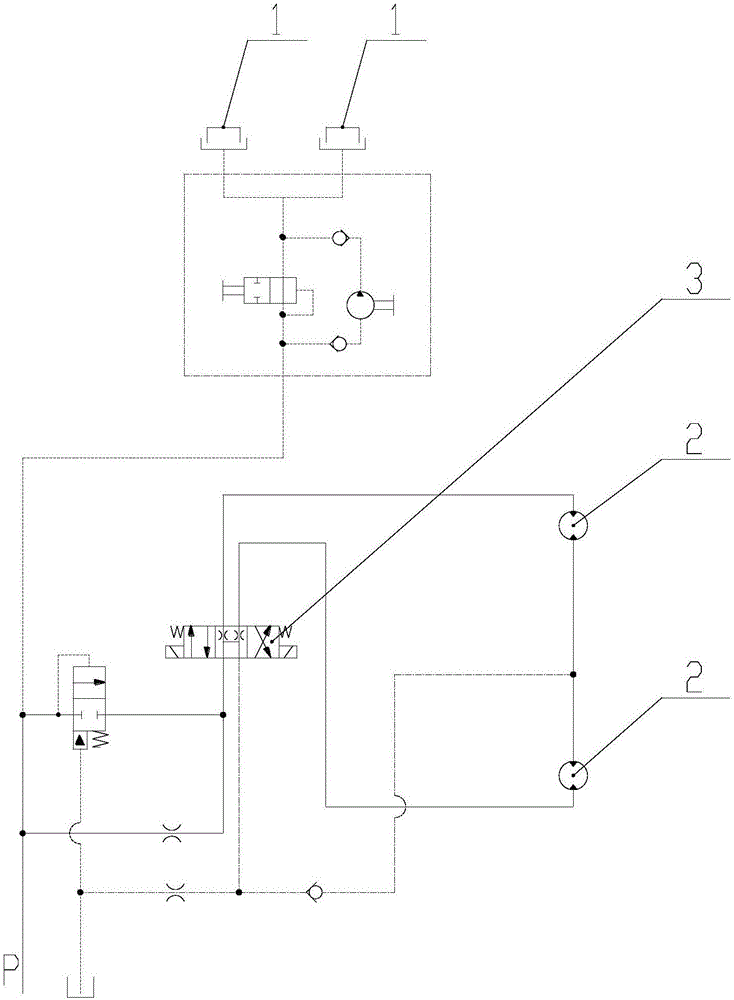

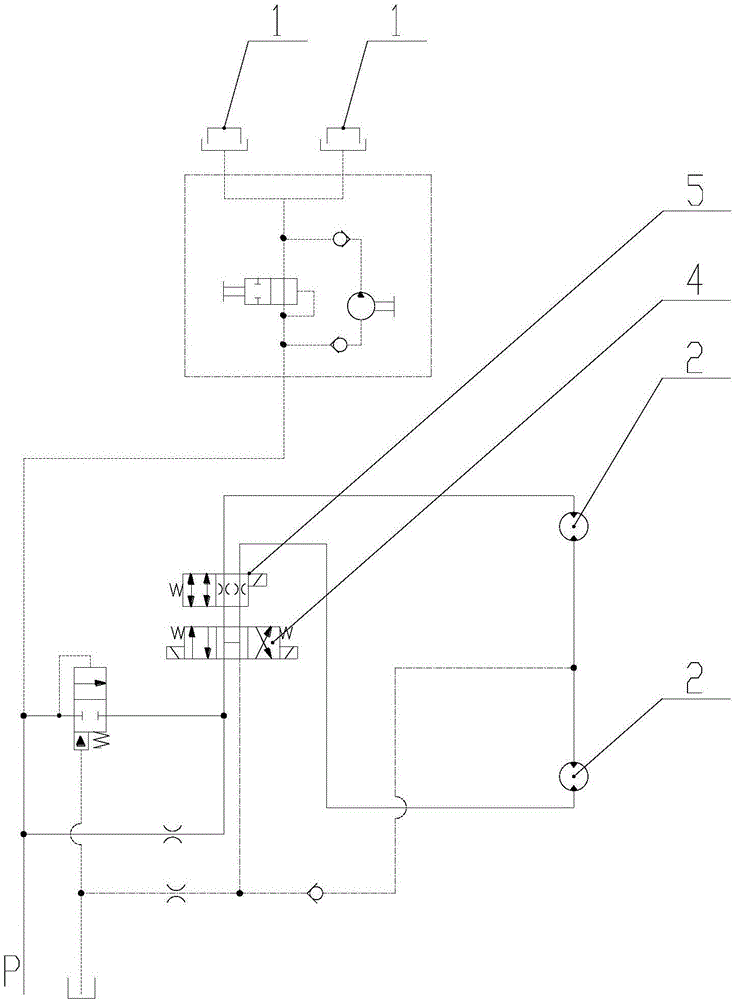

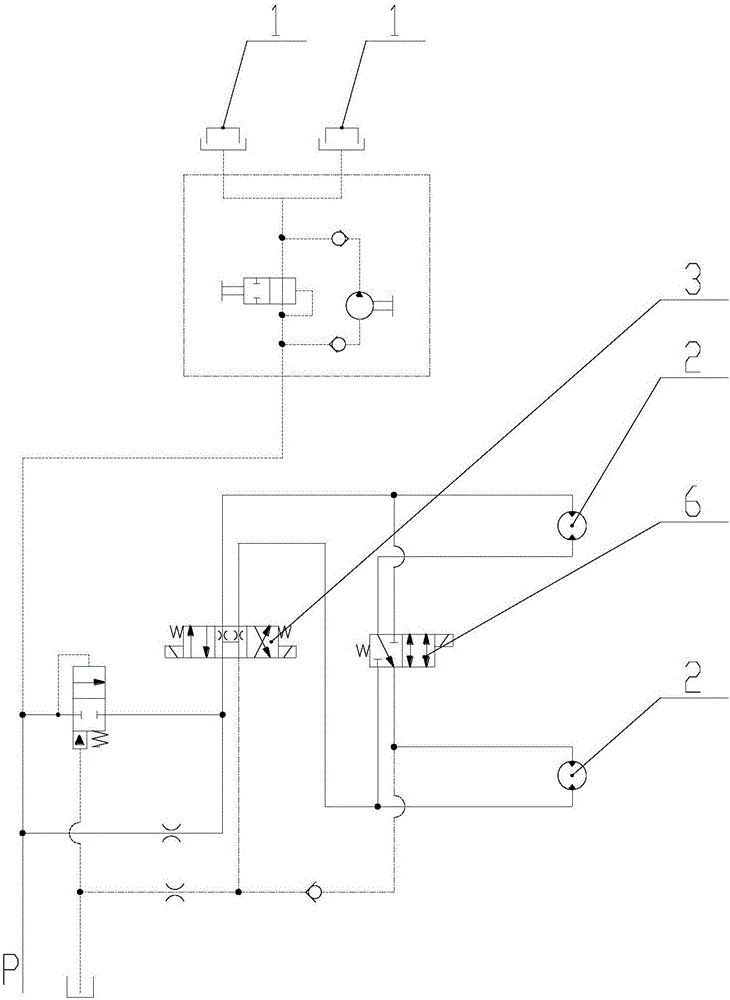

Lifting platform and hydraulic driving system thereof

InactiveCN106050769AShorter braking distanceImprove stabilityServomotor componentsServomotorsFuel tankControl theory

The invention discloses a hydraulic driving system of a lifting platform. The hydraulic driving system comprises a brake, a motor and a damping reversing device, wherein the motor is communicated with an oil pump and an oil tank by virtue of the damping reversing device, the flow direction of hydraulic oil in the motor can be controlled by the damping reversing device, and the flow of the hydraulic oil in the motor is blocked after the oil supply is stopped. When braking is needed, the brake is operated, the oil supply to the motor is stopped, so that the flow of the hydraulic oil in the motor is blocked, the oil return backpressure of the motor is increased, the speed of the motor is reduced, and the brake is matched, so that the braking distance can be shortened, and the stability and comfort are increased. The invention further discloses the lifting platform, which comprises the hydraulic driving system.

Owner:HUNAN SINOBOOM HEAVY IND

Liquid container

Owner:SEIKO EPSON CORP

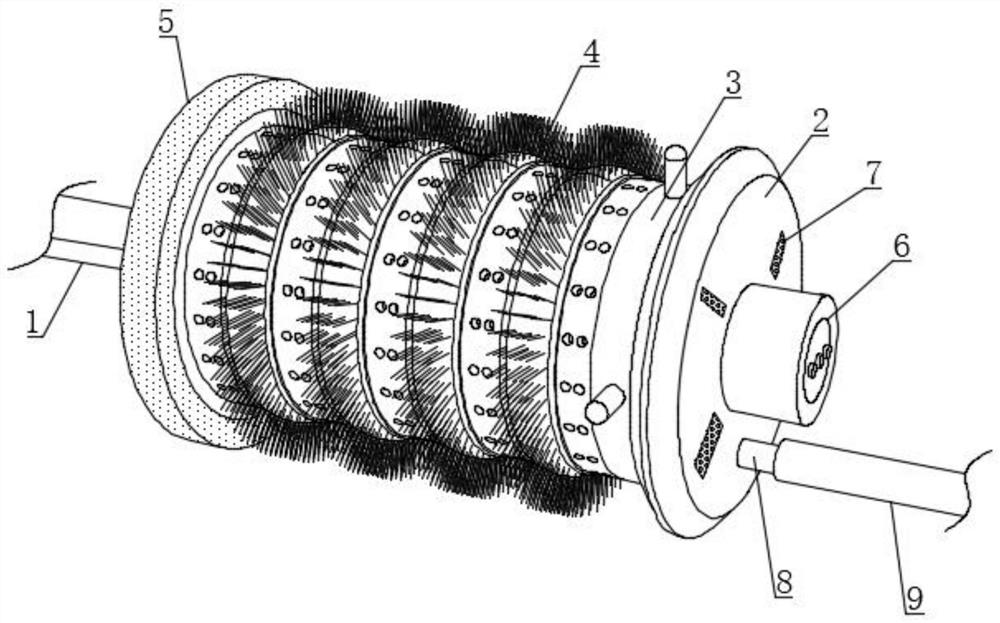

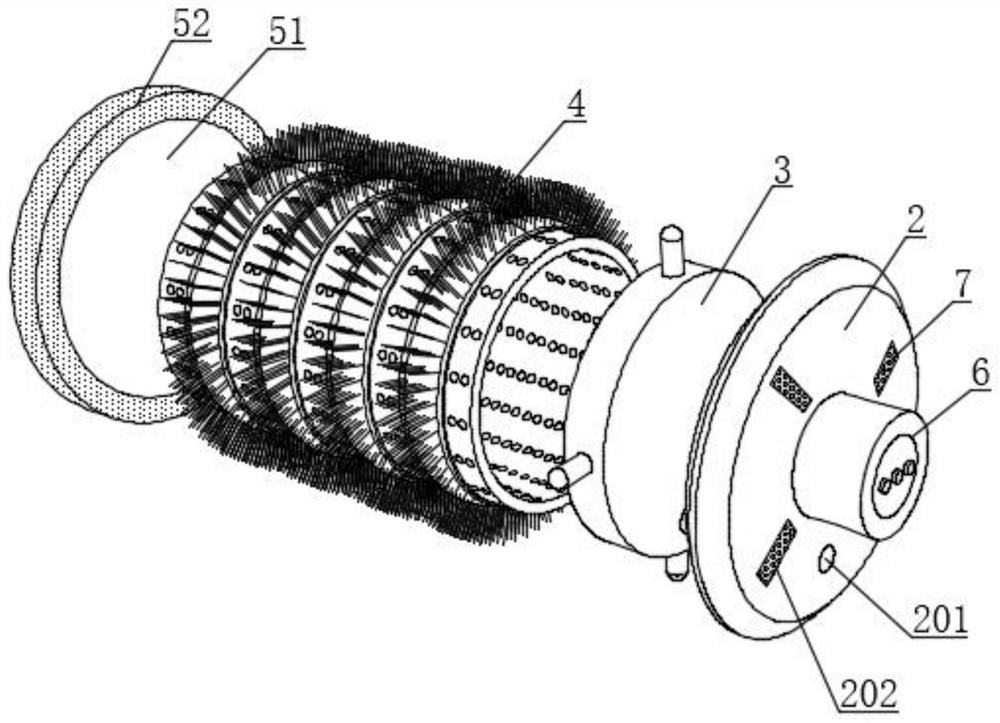

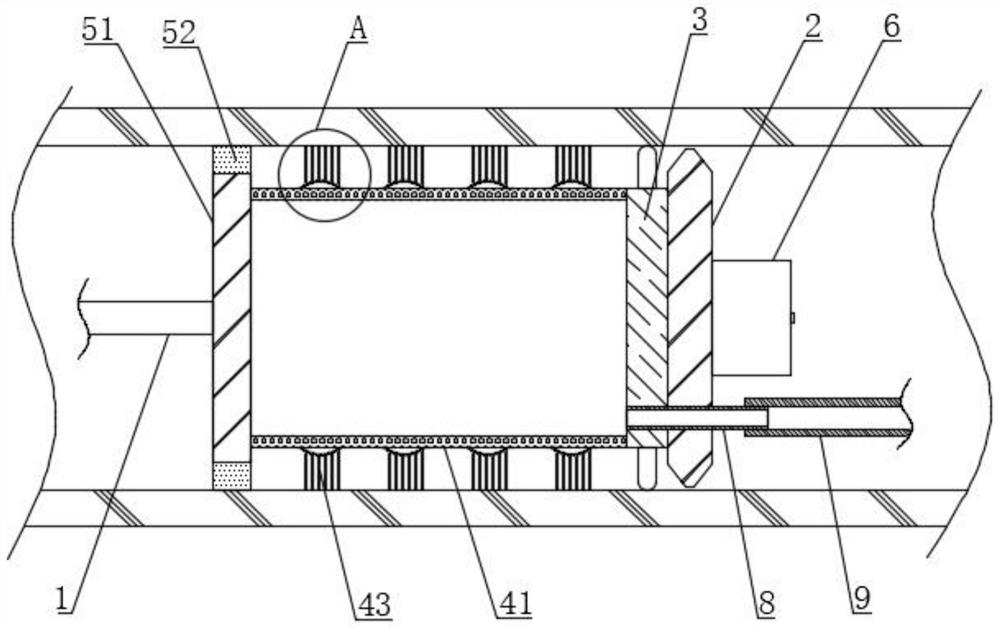

Universal inner wall corrosion prevention and film forming device for bent and straight pipes

PendingCN111804523AEliminate air gapsQuality improvementPretreated surfacesCoatingsEngineeringMechanical engineering

The invention discloses a universal inner wall corrosion prevention and film forming device for bent and straight pipes, and belongs to the field of pipe inner wall corrosion prevention. The universalinner wall corrosion prevention and film forming device for the bent and straight pipes comprises a scraping plate and a sealing plate, wherein the end, close to the sealing plate, of the scraping plate is fixedly connected with a positioning plate, and an inner adaptive applying pipe is fixedly connected between the sealing plate and the positioning plate. According to the universal inner wall corrosion prevention and film forming device for the bent and straight pipes, the space between the sealing plate and the positioning plate is fully filled with a corrosion inhibitor, the corrosion inhibitor makes full contact with the inner wall of a pipe in the area, meanwhile, a plurality of soft brushes are used for brushing the inner wall of the pipe, so that the air gap between the corrosioninhibitor and the inner wall part of the pipe is effectively eliminated, and a uniform and complete anti-corrosion film is formed on the inner wall of the pipe; and the device has the characteristicsof high quality and high benefit in film formation, can be simultaneously suitable for the straight pipes and the irregular bent pipes through the internal adaptive applying pipe consisting of a rubber hose, elastic belts and the soft brushes, can carry out coating film formation process with the same effect on the straight and bent pipes, and has the characteristic of ultrahigh practicability.

Owner:南通宝得利机械制造有限公司

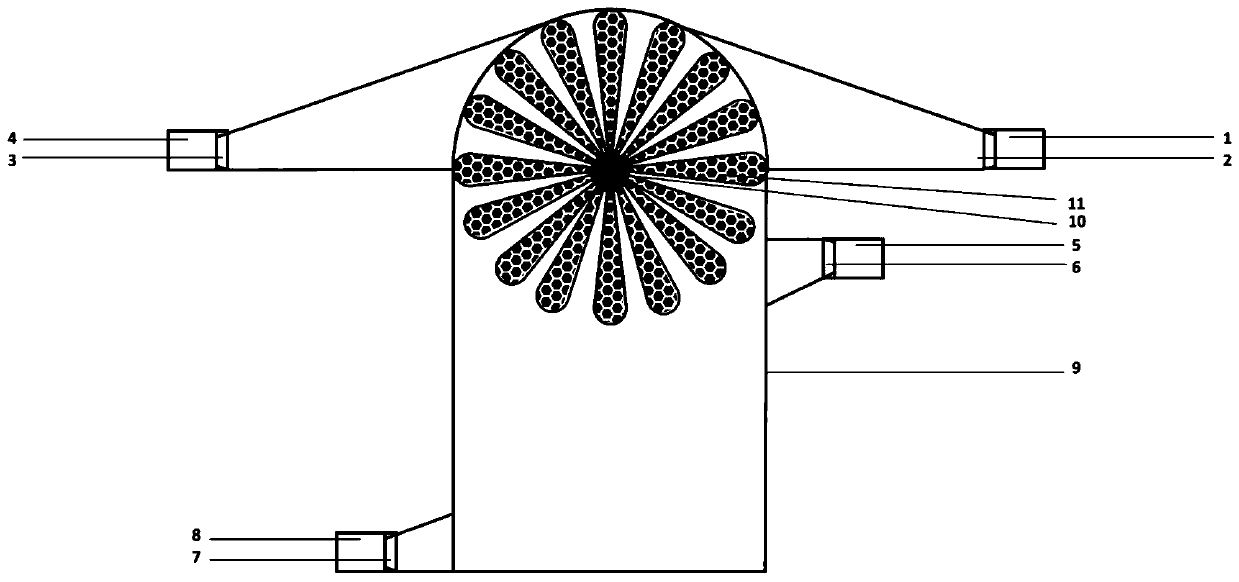

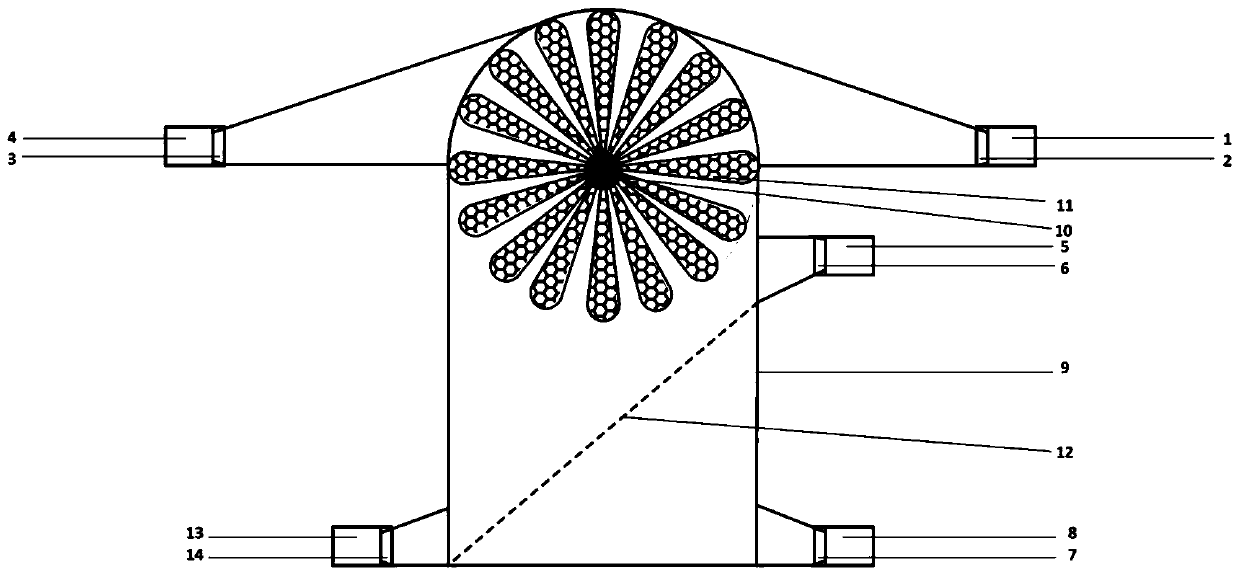

Self-circulation flue gas dust collecting device and method

The invention relates to a self-circulation flue gas dust collecting device and a method. A porous impeller structure is applied to a dust collecting device cavity, a cleaning fluid acts with potential energy to flow from top to bottom so as to drive a dust collecting impeller to rotate clockwise, no additional action is needed, and a self-circulation function of the device is realized; an impeller rotation process also has a certain promotion function on feeding flue gas; with the novel porous impeller structure, pollutant particles in the flue gas can be adsorbed and washed separately, so that the dust collecting efficiency is greatly improved; meanwhile, the dust collecting impeller is made of heat insulation materials, the tail end of the impeller is tightly connected with the shell, and the contraflow of the flue gas and the cleaning fluid is utilized for driving the dust collecting impeller to rotate clockwise, so that the flue gas is prevented from directing contacting the cleaning fluid, the loss of flue gas waste heat during a dust collecting process is avoided, meanwhile, the dust collecting process is prevented from obstructing the flowing of the flue gas, and the power consumption in the dust collecting process is reduced to a greater extent. The whole device has the characteristics of high dust collecting efficiency, low manufacturing and operating cost, wide application temperature range, and the like.

Owner:XI AN JIAOTONG UNIV

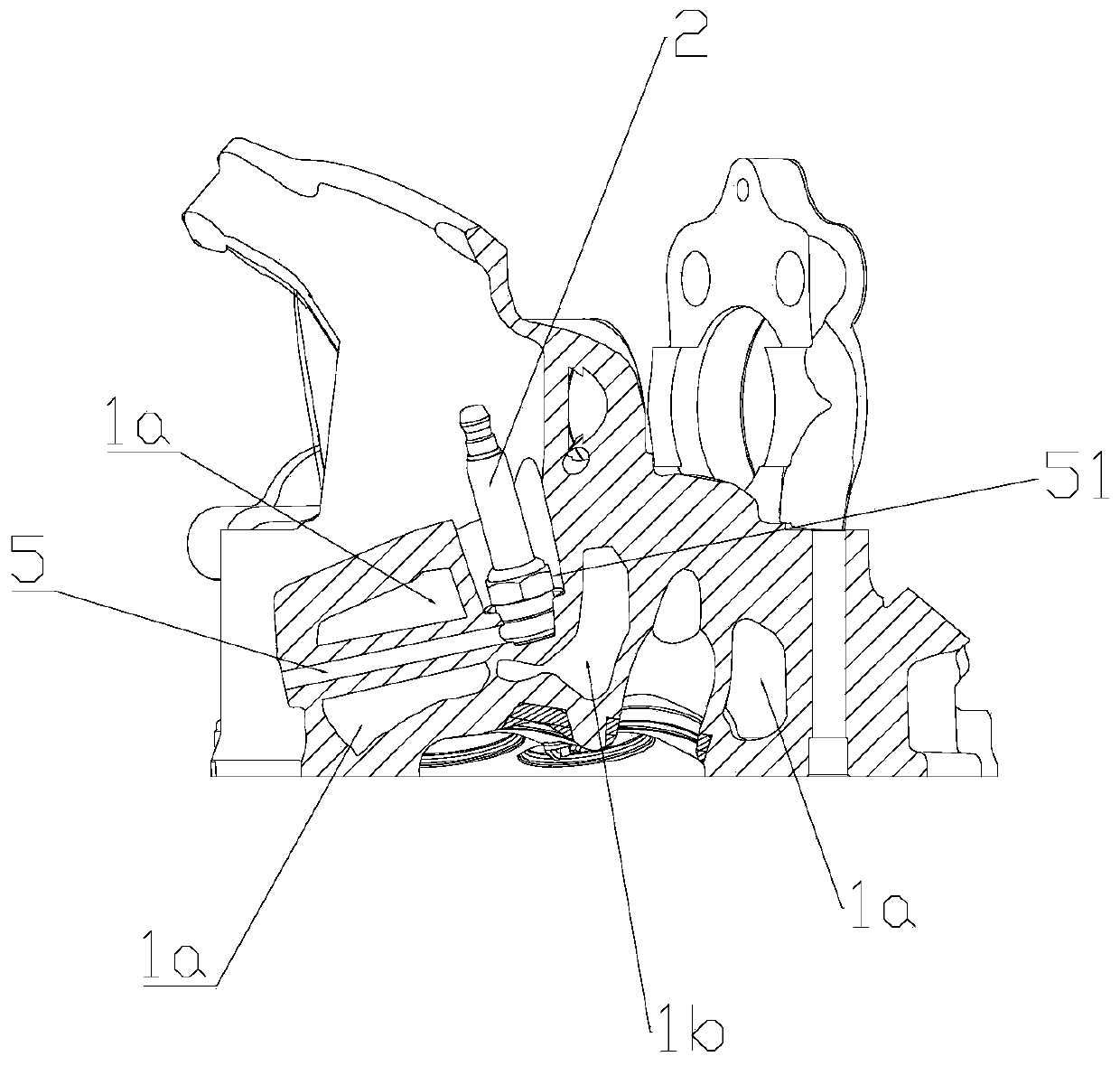

Reinforced cooling type air cylinder head

PendingCN111075590AEnsure normal flowFlow obstructionLiquid coolingCylinder headsExhaust valveCylinder head

The invention discloses a reinforced cooling type air cylinder head. The reinforced cooling type air cylinder head comprises an air cylinder head body, the air cylinder head body is provided with a water inlet and a water outlet, the water inlet is formed in the lower end face of the air cylinder head body, the water outlet is formed in the highest point of a water level in the air cylinder head body, the air cylinder head body is internally provided with a main water channel cavity, a spark plug water channel cavity and an exhaust channel nose bridge water channel cavity, the main water channel cavity communicates with the water inlet and the water outlet, and cooling water flows in from the water inlet and is discharged from the water outlet to provide timely cooling for the air cylinderhead body; the spark plug water channel cavity is formed in the root of a spark plug in a surrounding mode and communicates with the main water channel cavity, and cooling water circulating in the main water channel cavity provides timely cooling for the root of the spark plug; and the exhaust channel nose bridge water channel cavity is arranged in a nose bridge area between two exhaust doors conformally and communicates with the main water channel cavity, and the cooling water circulating in the main water channel cavity provides timely cooling for an exhaust channel nose bridge area.

Owner:CHONGQING LONCIN MOTOR +1

Wedge groove curvature sealing structure for dynamic and static gaps for nuclear main pump

ActiveCN102155431AAvoid breakingShorten tooth aspect ratioPump componentsPumpsEngineeringHigh pressure

The invention relates to a wedge groove curvature sealing structure for dynamic and static gaps for a nuclear main pump. A static component of a nuclear main pump is provided with a sealing ring; the inner surface of the sealing ring is provided with a curvature sealing groove; the sealing groove is arranged at the inner surface of the sealing ring according to the opposite direction of the rotation of a rotor; a rotary component rotates to drive a fluid to rotate; and a working medium enters the curvature sealing groove, flowing which is opposite to the direction of a leakage flow is formed, the fluid forms the pressure resistance at the inlet of the sealing groove to block the leakage flow. The nuclear main pump provided by the invention is used under the condition of a high-pressure high-temperature high-speed large flow rate working condition, leakage flow rate can be controlled steadily and temporarily under a backflow extreme working condition, and is safe, durable and has a good leakage control effect.

Owner:DALIAN UNIV OF TECH

Preparation method of polyurethane waterproof paint

InactiveCN107903798AHigh mechanical strengthBig room for improvementPolyurea/polyurethane coatingsPrepolymerChemistry

The invention discloses a preparation method of polyurethane waterproof paint. The preparation method comprises the following steps: S1, dehydrating and cooling 15.04-17.8 parts by weight of polypropylene oxide glycol and 1.54-2.81 parts by weight of propylene oxide to 68-70 DEG C, then mixing with 20 parts by weight of diphenylmethane diisocyanate, raising the temperature to 76-78 DEG C, reactingfor 3.5-4.5 hours, keeping stirring in the reaction process to obtain a prepolymer; adding a surfactant and a solid filler into a ball mill, conducting ball milling for 45-60 minutes, keeping the ball milling temperature at 90-98 DEG C, then cooling to 40-50 DEG C, adding 0.5-0.7 part by weight of a defoamer, 12-15 parts by weight of methyl ethyl ketone and 0.6-0.8 part by weight of dioctyl phthalate, conducting ball milling for 30 minutes to obtain a component A; and sequentially adding 1.7-2.5 parts by weight of polyurethane acrylic resin, 17-19 parts by weight of the component A, 0.8-1.3 parts by weight of o-phenylenediamine, 0.021-0.023 part by weight of di-n-butyltin dilaurate and 0.6-1.1 parts by weight of dibutyl phthalate into 20-24 parts by weight of a prepolymer, and stirring evenly at the temperature of 52-55 DEG C to obtain the waterproof paint. The preparation method solves the problem of poor mobility of the existing single-component polyurethane waterproof paint.

Owner:CHANGSHA QIUDIANBING INFORMATION TECH CO LTD

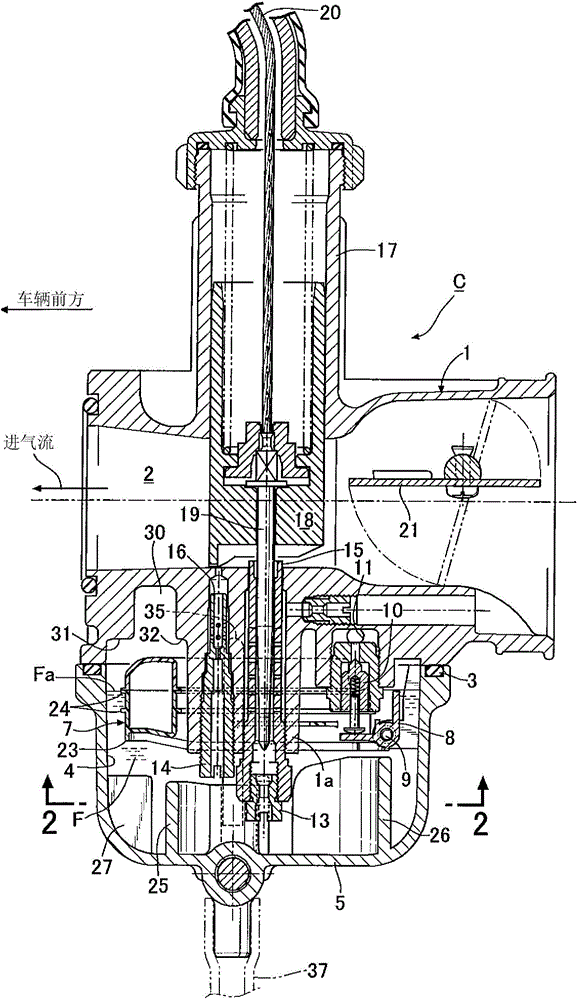

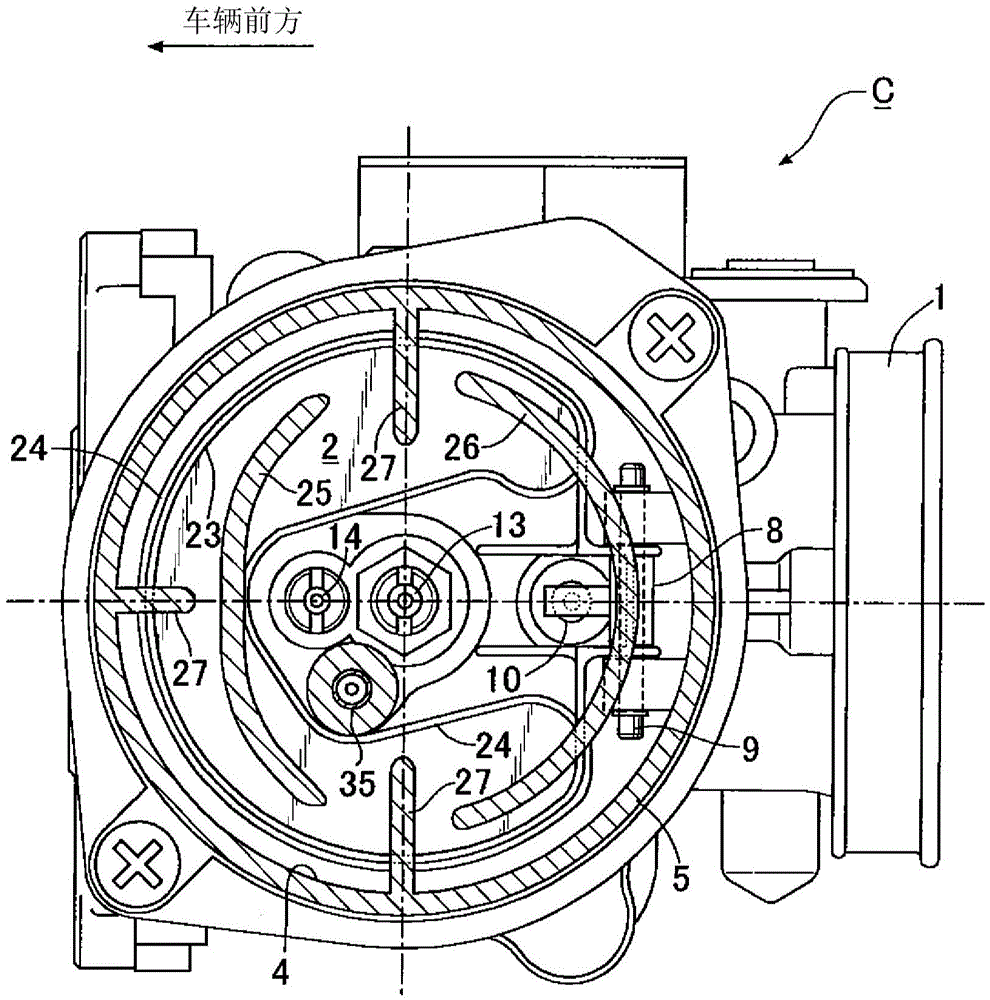

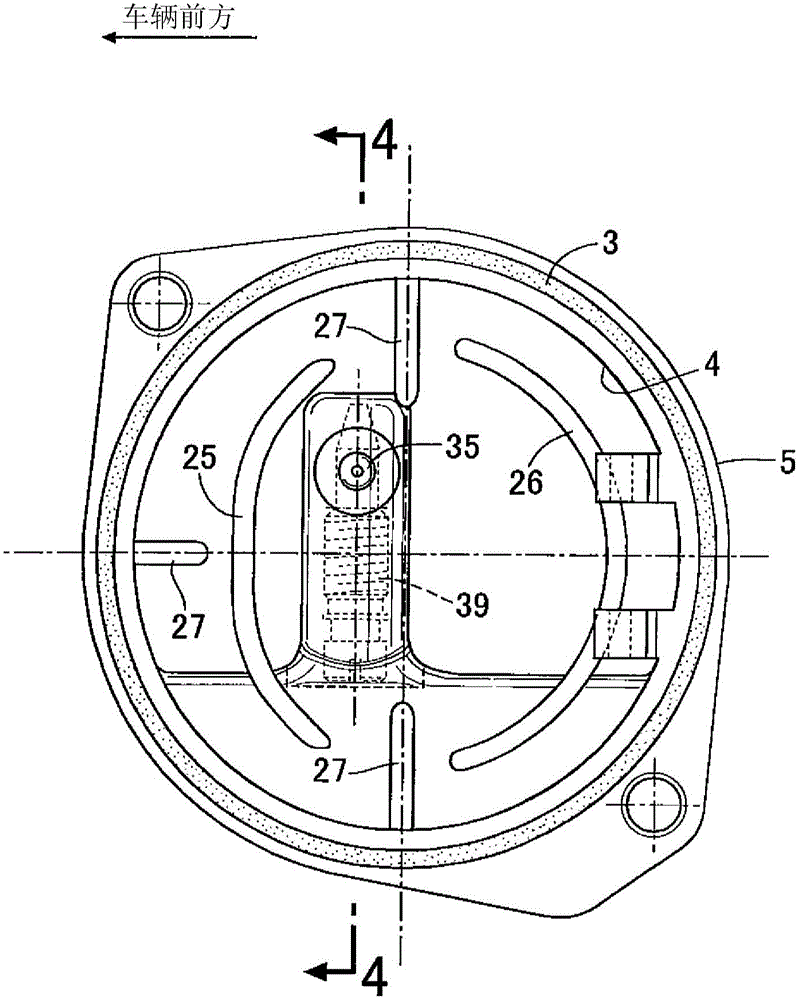

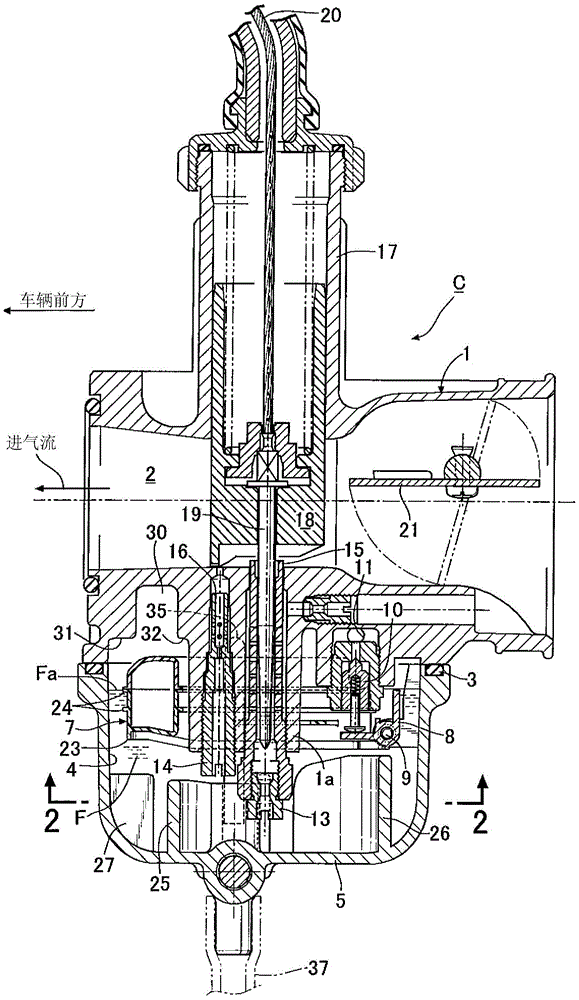

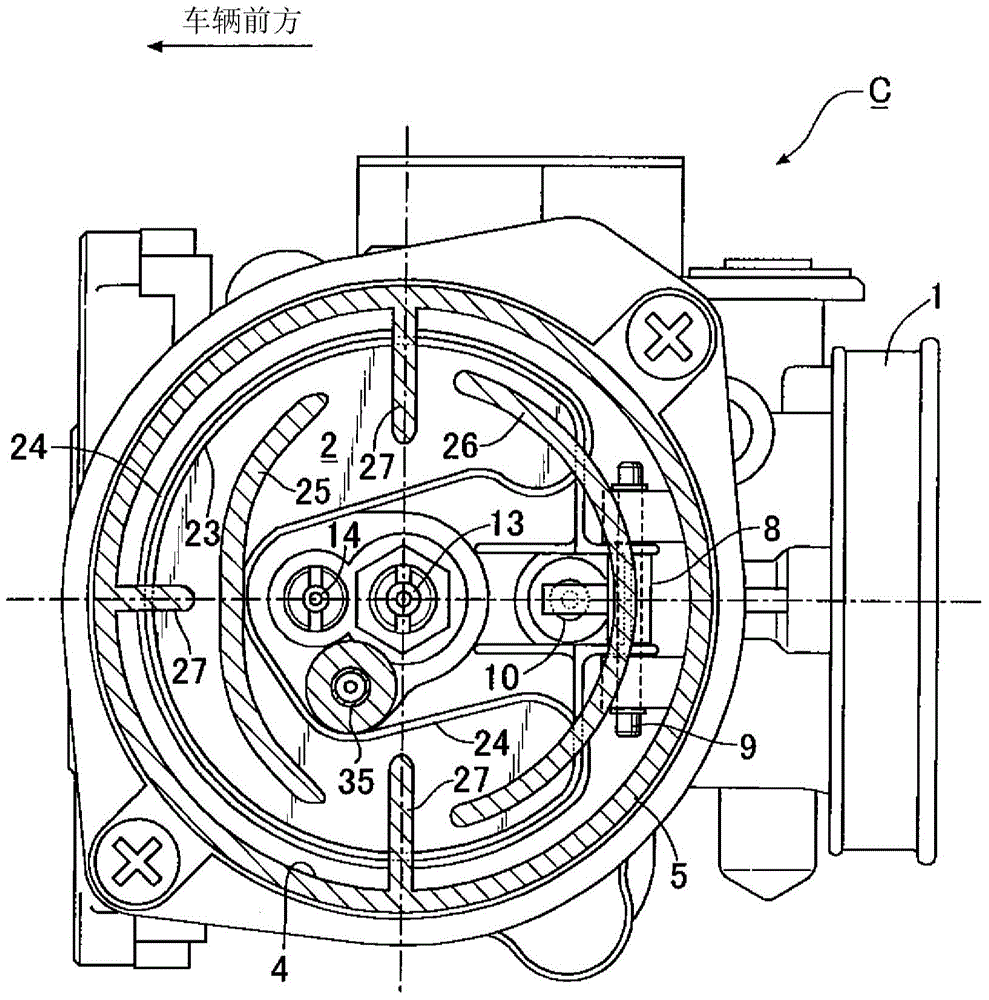

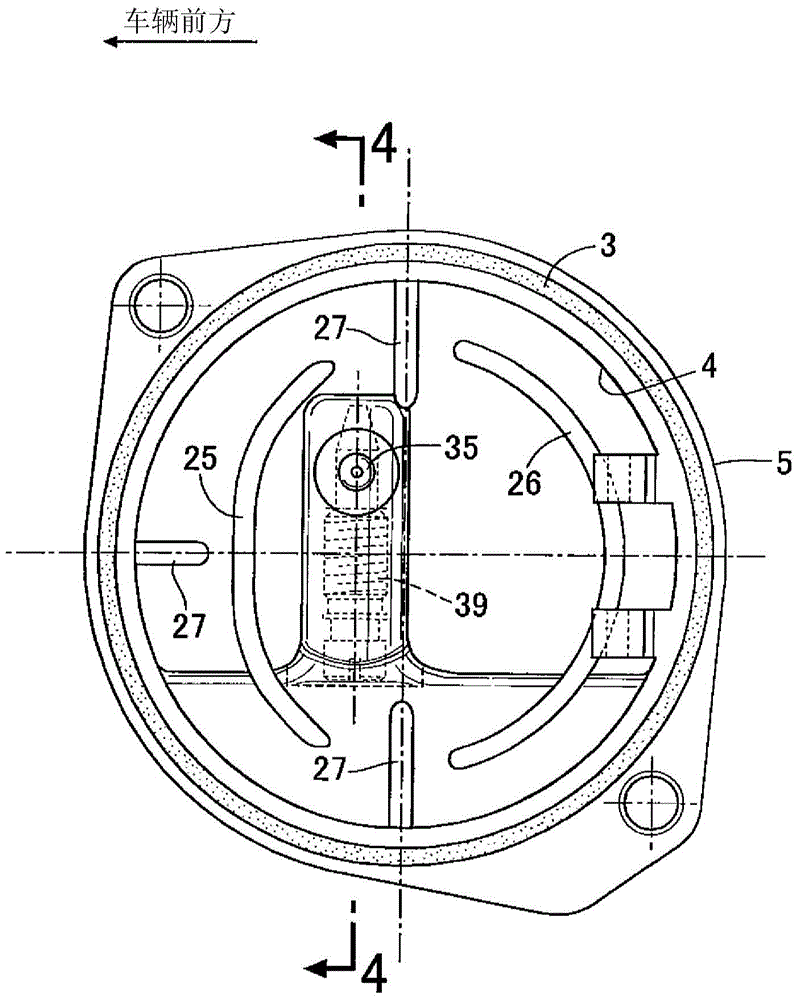

Carburetor

ActiveCN104061090ASuppress violent shakingPrevent useless opening and closingFloat-controlled apparatusMachines/enginesFloat chamberMarine engineering

The invention provides a carburetor, and fluctuation of an oil level of a fuel in a float chamber without increasing the diameter of the float chamber. A floator (7) forms a shape of a major arc which surrounds a fuel boss (1a) and is open in a pivot (9) side, and an arc-shaped upper longitudinal rib (23) protruding downward from a lower outer peripheral edge of the floator (7) is formed on the floator (7); and, on the other hand, an arc-shaped lower longitudinal rib (25) is formed on the float chamber (5), and the lower longitudinal rib (25) is erected from the bottom of the float chamber (5) to the lower surface of the floator (7) and is disposed on the inner side of the upper longitudinal rib (23).

Owner:HITACHI ASTEMO LTD

A method for improving high temperature performance of alumina ceramic core

InactiveCN104387038BIncrease deflectionHigh porosityFoundry mouldsFoundry coresCore productManufacturing technology

The invention provides a method for improving the high-temperature properties of an alumina based ceramic core for solving the problem that a domestic alumina based ceramic core has deflection difference at 1600 DEG C and fails to meet the requirement of pouring of single crystal blades at above 1550 DEG C, and belong to the technical field of alumina based ceramic core manufacturing. The method comprises the following steps: adding porous high-purity alumina to alumina based ceramic core powder, performing core pressing, primary roasting, primary strengthening by use of a high-temperature strengthening liquid, secondary roasting, secondary strengthening by use of the high-temperature strengthening liquid, third strengthening by use of the high-temperature strengthening liquid and primary strengthening by use of a low-temperature strengthening liquid, and finally roasting to obtain the core product. After the alumina based ceramic core is treated by use of the method, the deflection of the alumina based ceramic core is reduced to 0-0.5mm; after double roasting and double strengthening, the strength of the core is above 15Ma; after double roasting and triple strengthening, the strength of the core can be above 25Ma; as a result, the high-temperature properties of the alumina based ceramic core are greatly improved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

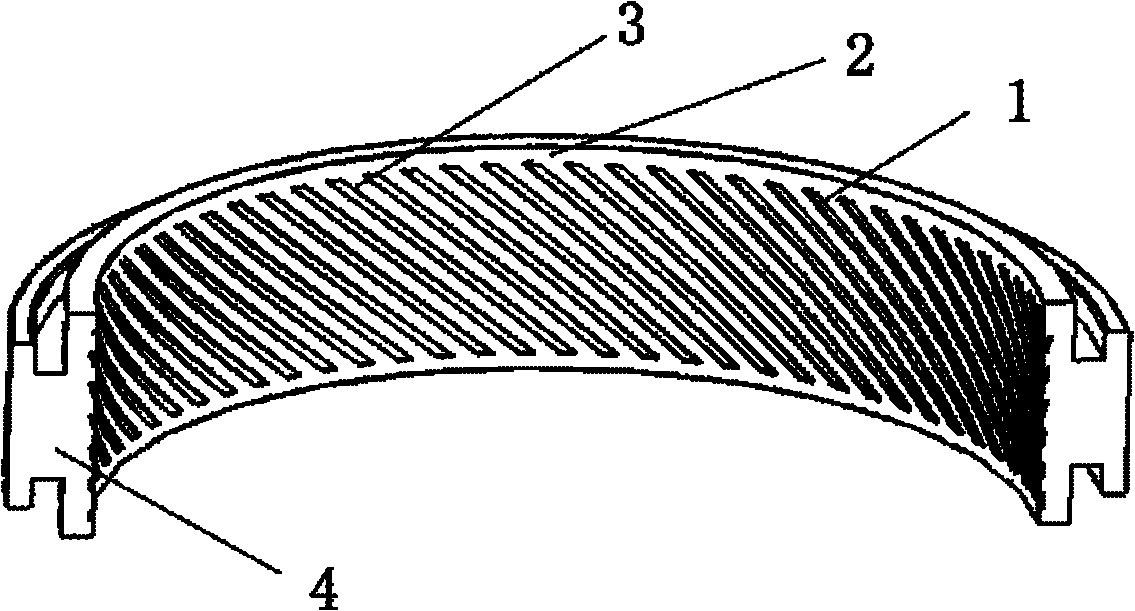

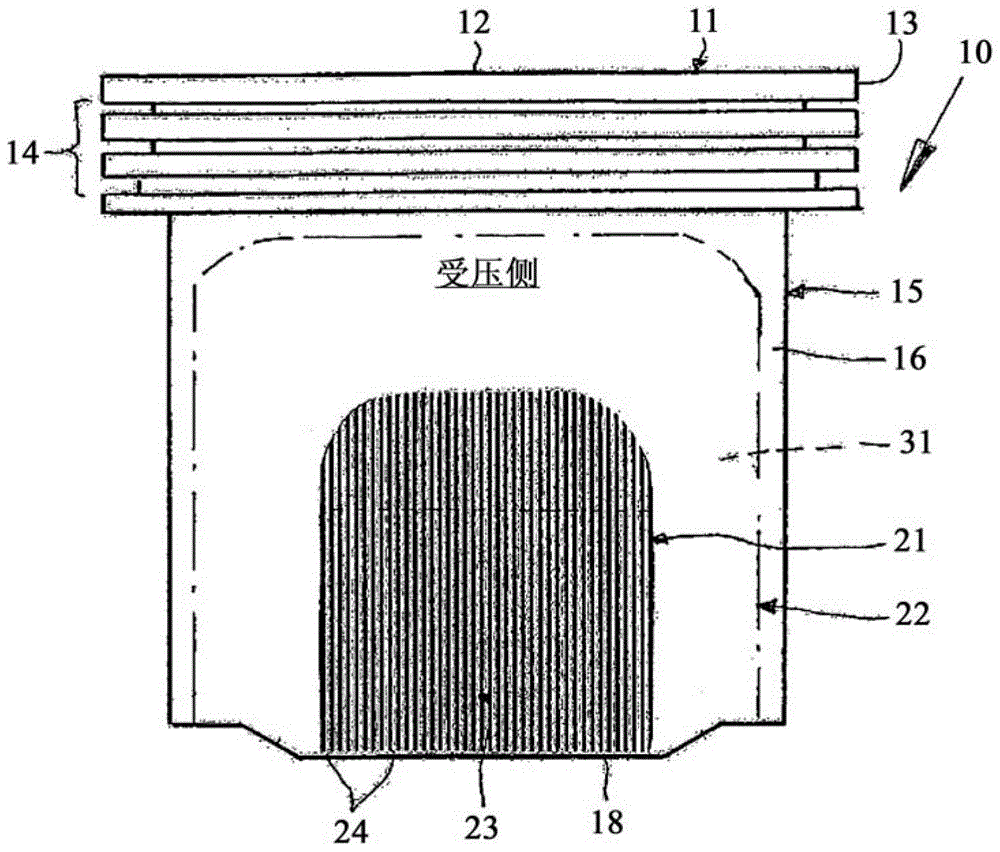

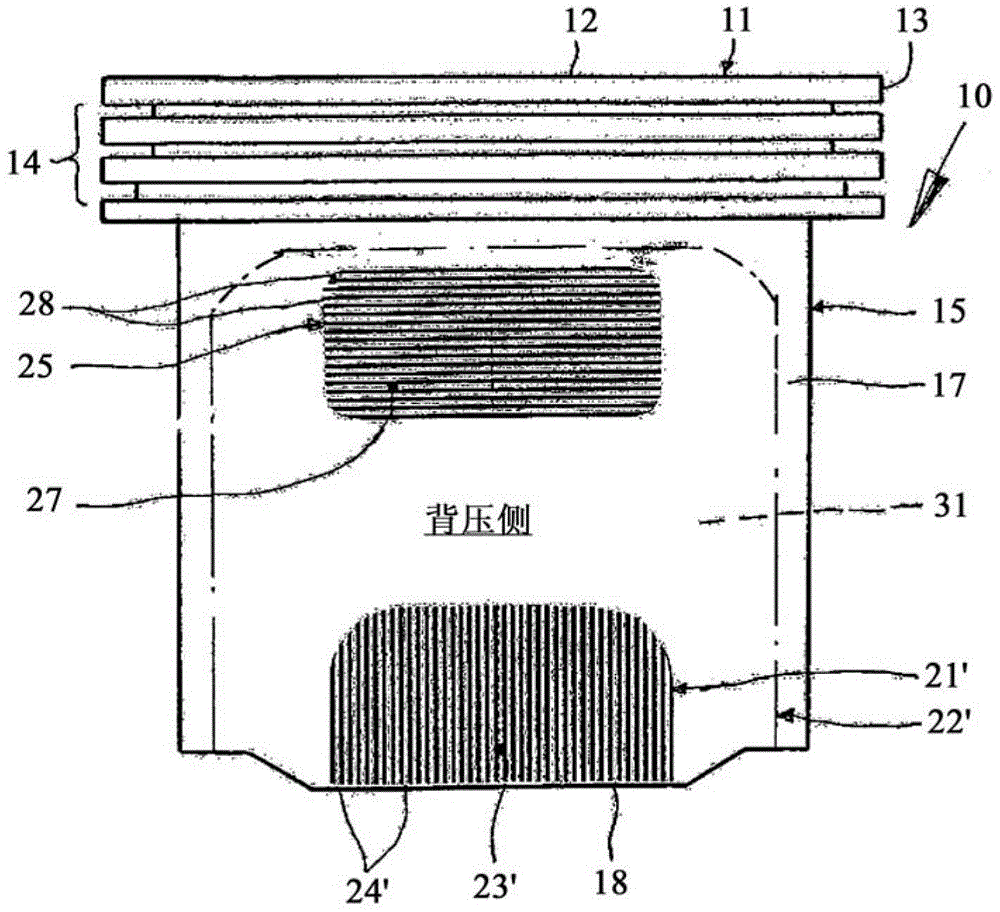

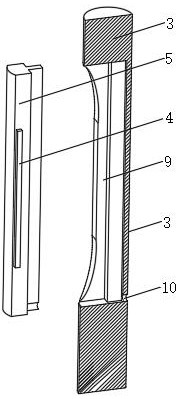

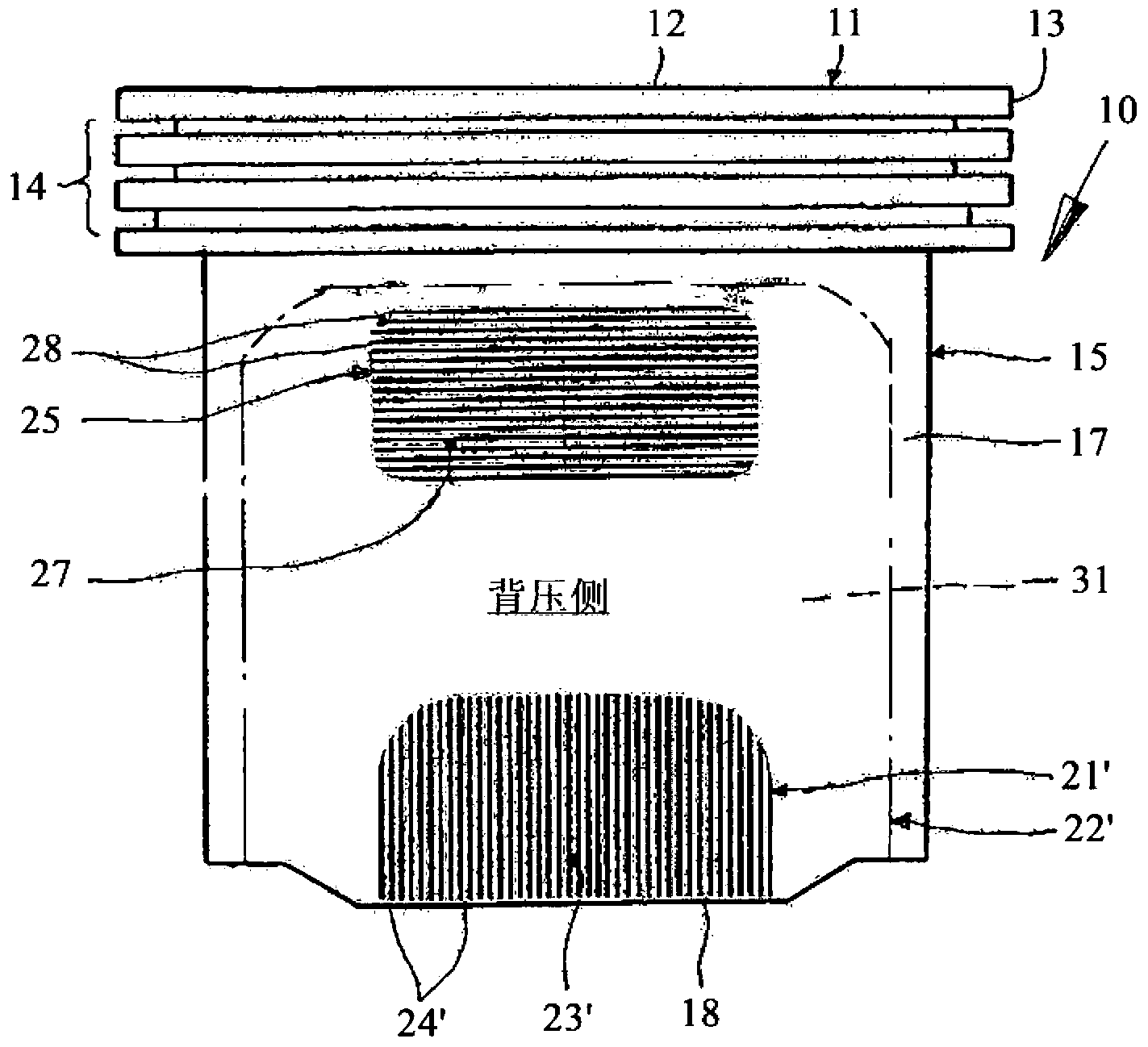

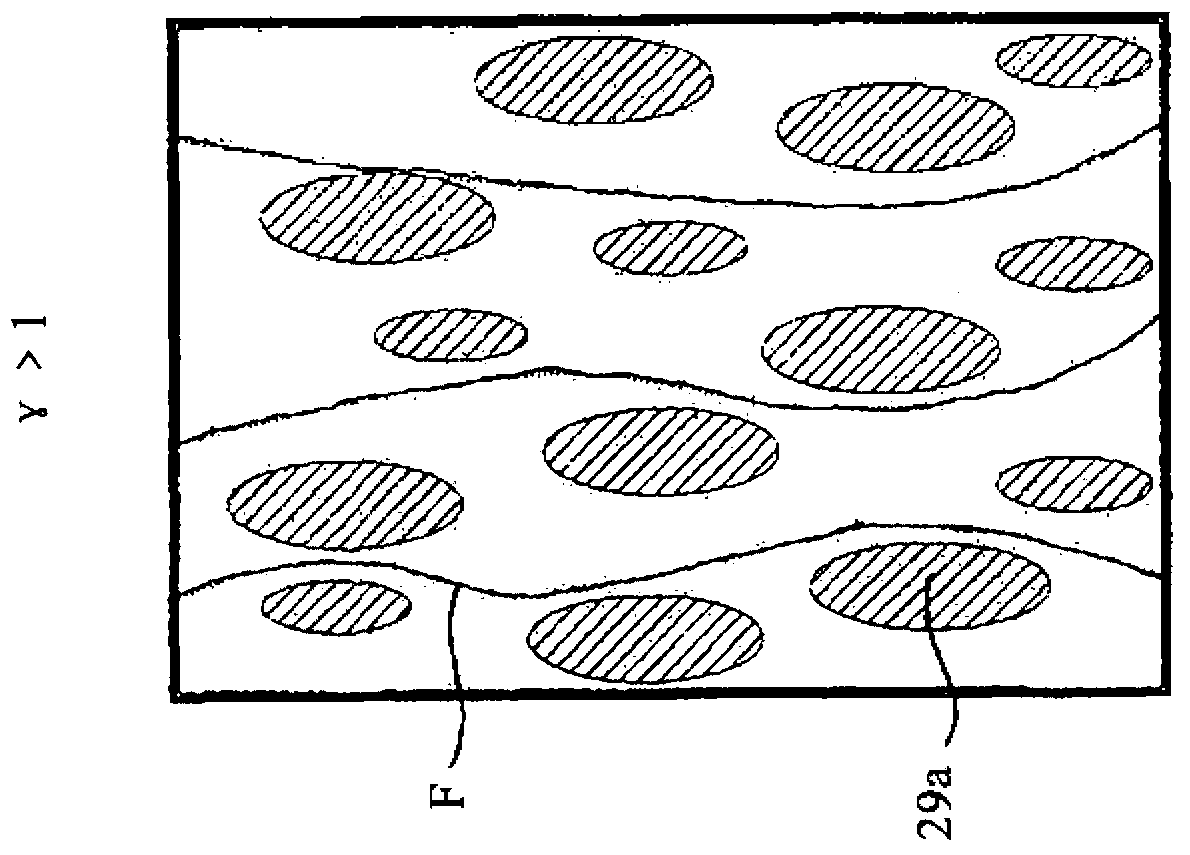

Pistons for internal combustion engines

InactiveCN103210198BFlow obstructionReduce lossPlungersMachines/enginesExternal combustion engineEngineering

The invention relates to a piston (10) for an internal combustion engine having a piston head (11) and a piston skirt (15) defined by a lower skirt (18), wherein the piston skirt (15) has a The friction surface (16) of the side (DS) and the friction surface (17) corresponding to the back pressure side (GDS) of the device, and a section (21, 21') is subordinate to these two friction surfaces (16, 17 ), which section extends from the lower skirt ( 18 ) and is subjected to the greatest load during operation of the internal combustion engine. It is provided according to the invention that the section ( 21 ) of the friction surface ( 16 ) corresponding to the pressure side (DS) and / or the section ( 21 ′) of the friction surface ( 17 ) of the back pressure side (GDS) is arranged There is a coating (23, 23') which has vertically running grooves (24, 24').

Owner:MAHLE INT GMBH

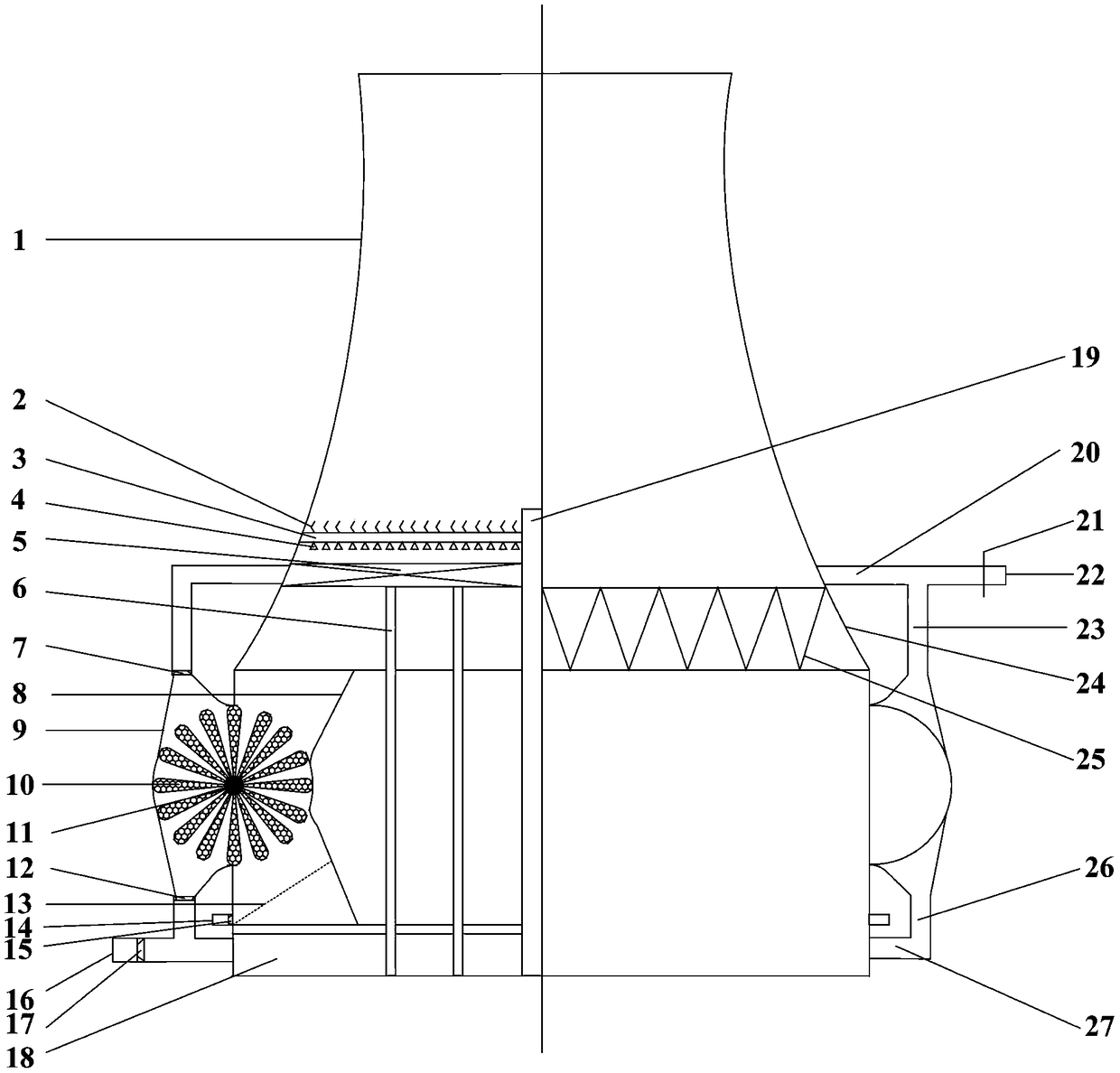

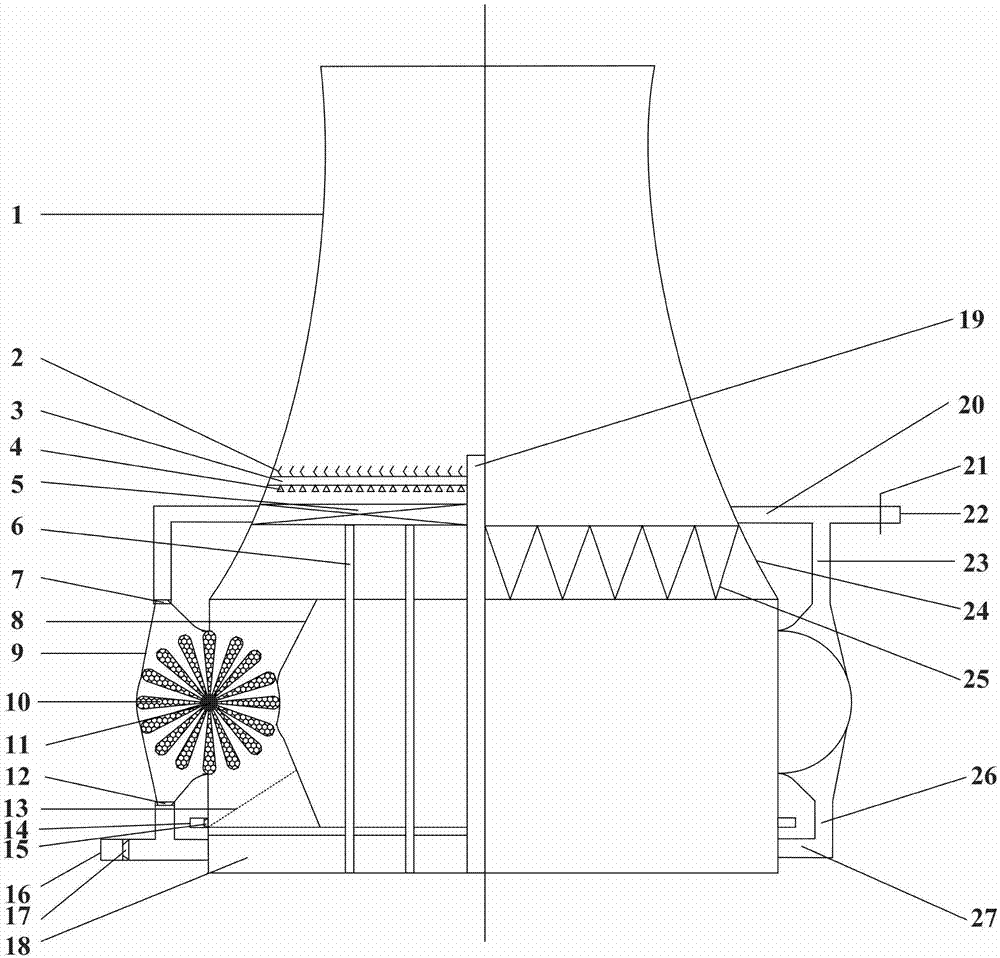

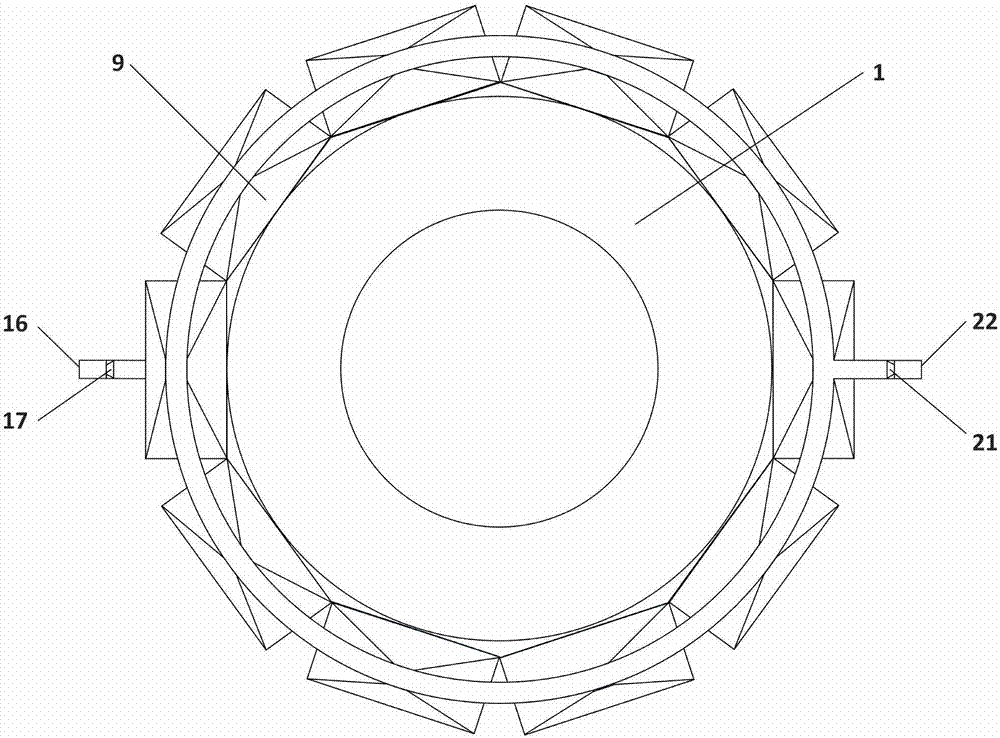

A kind of self-circulating flue gas dust removal cooling tower and method

ActiveCN107198924BRealize self-circulation functionImprove dust removal effectCombination devicesGas treatmentCooling towerThermodynamics

The invention discloses a self-circulation flue gas dedusting and cooling tower and a method. A porous impeller structure is applied into a dedusting device cavity, potential energy of water in the cooling tower is fully utilized to act to flow from top to bottom to drive a dedusting impeller to rotate clockwise, extra acting is avoided, and a self-circulation function is achieved; meanwhile, a flushing effect of the water in the cooling tower is fully utilized, a dedusting effect is well achieved, filtering of a filter screen can guarantee that circulation water can be recycled; a certain promoting effect on flue gas flowing into in an impeller rotating process is achieved; adsorption and flushing on pollutant particles in the flue gas can be separately performed by the porous impeller structure, so that dedusting efficiency is obviously improved; reversed flowing of the flue gas and water is utilized to drive the dedusting impeller to rotate clockwise, the flue gas is prevented from directly contacting the water, waste heat loss of the flue gas in a dedusting process is avoided; meanwhile, the flue gas is not prevented from flowing in the dedusting process, and power consumption in the dedusting process is reduced to a larger extend.

Owner:XI AN JIAOTONG UNIV

A kind of heat-resistant foam gel and its preparation method and application

The invention discloses a temperature-resistant foam gel as well as a preparation method and application thereof. The temperature-resistant foam gel comprises the following components in percentage bymass: 0.3% of a polymer; 0.15%-0.35% of a cross-linking agent; 0.05%-0.15% of a foaming agent; and the balance water; the cross-linking agent is a cross-linking agent A or a mixture of the cross-linking agent A and a cross-linking agent B, and the cross-linking agent A is resorcinol; and the cross-linking agent B is formaldehyde. It is found by observing microstructures of water-based foam, polymer solution foam and the foam gel by using a microscope and a scanning electron microscope that common foam and polymer cannot keep stable for a long time due to flowing of a liquid film at normal temperature, and the liquid film of the foam gel forms a reticular gel structure, so that the viscosity and strength of the liquid film are enhanced, the flowing of the liquid film is hindered, and the foam gel has better stability at high temperature. It is shown by low-permeability fracture type rock core plugging experiment, the foam gel system can form effective plugging in rock cores, has a goodgas breakthrough inhibition effect, and has a wide application prospect in low-permeability oil reservoir.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

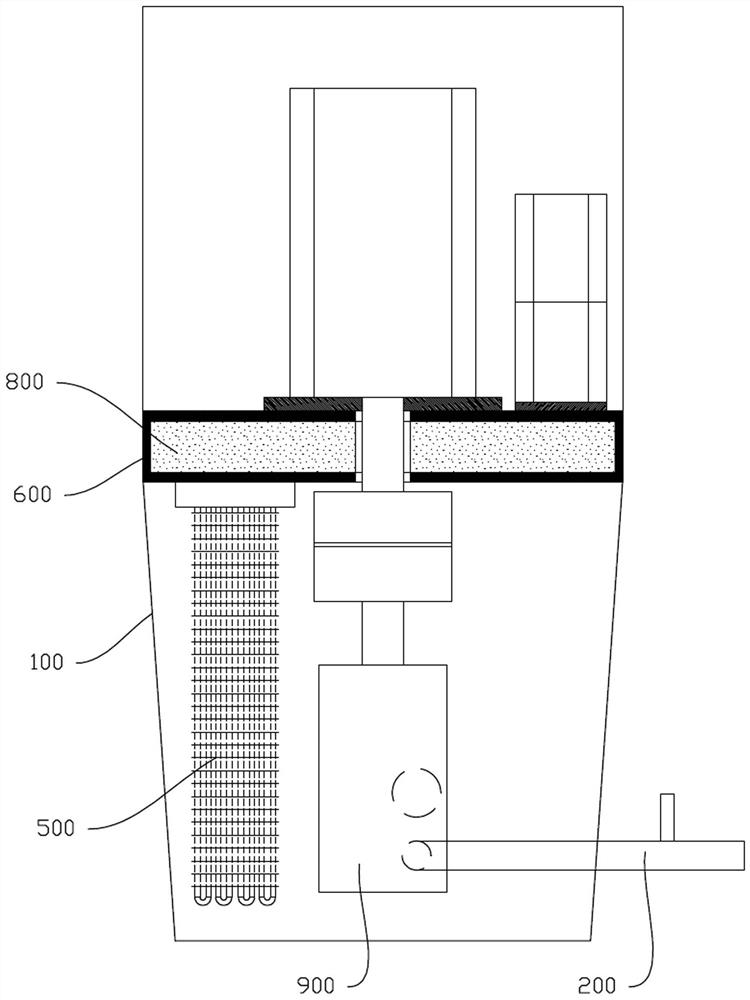

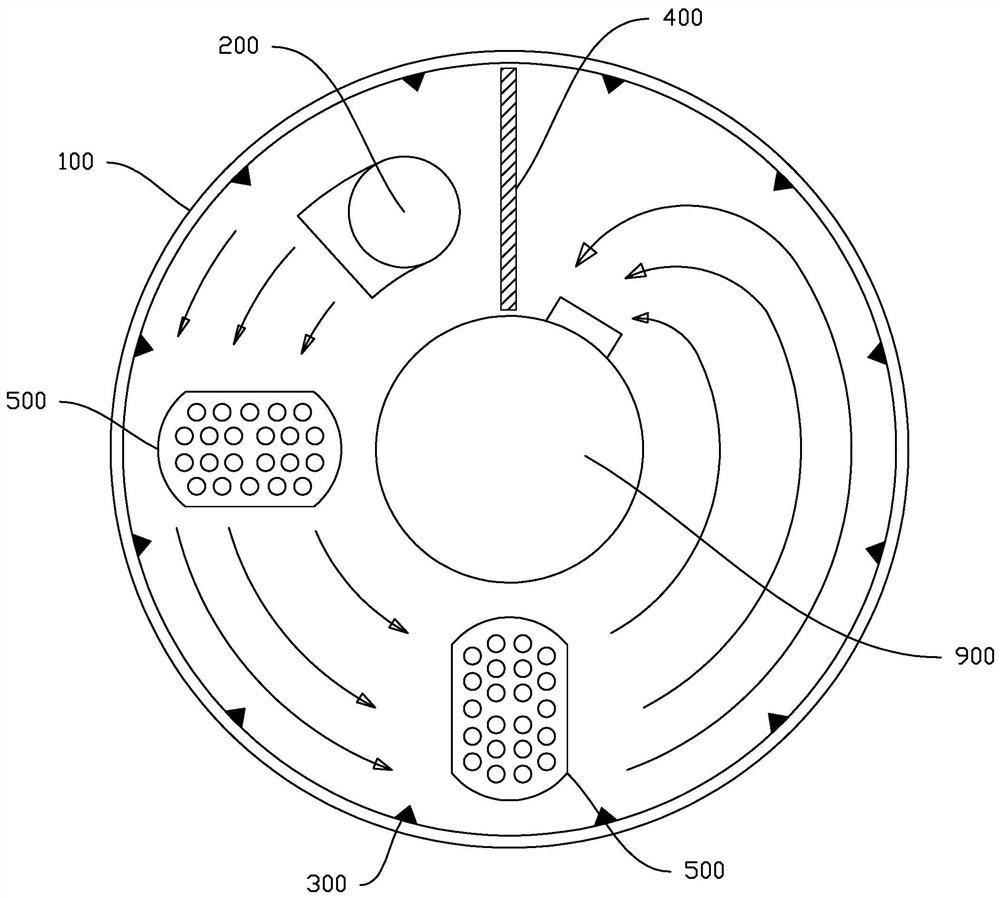

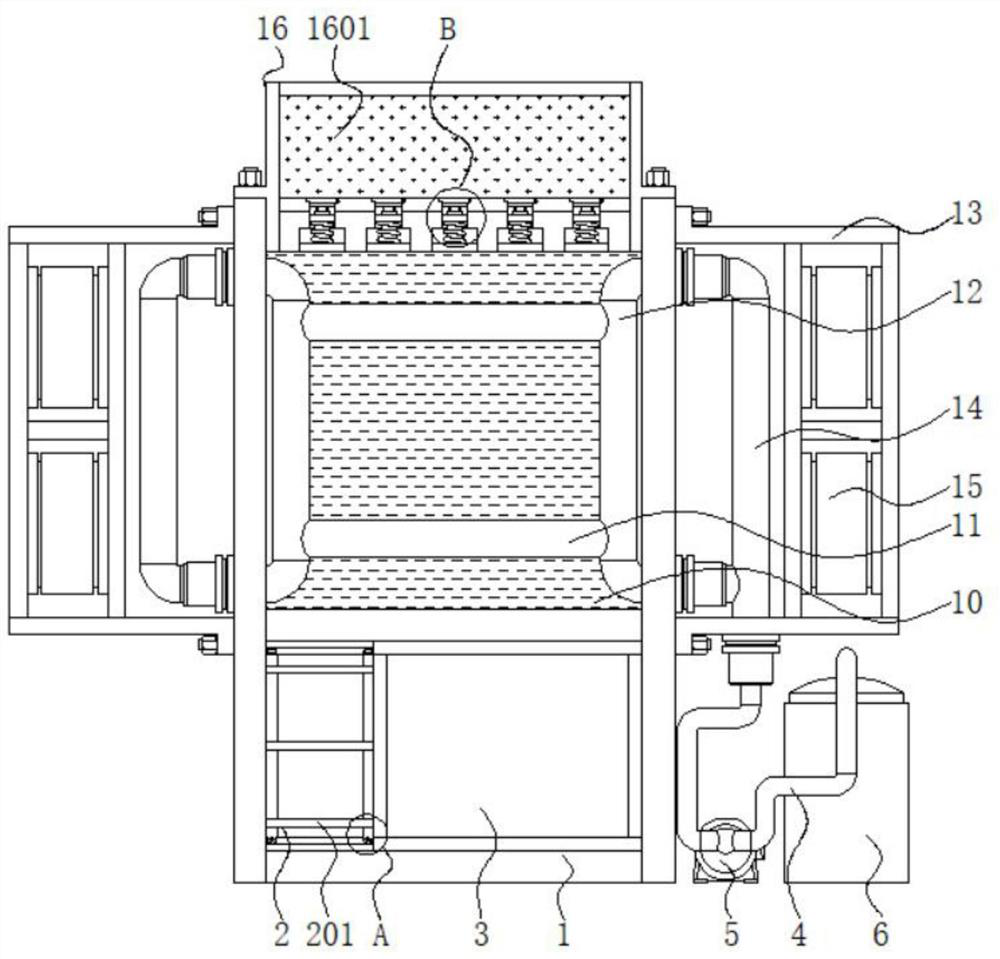

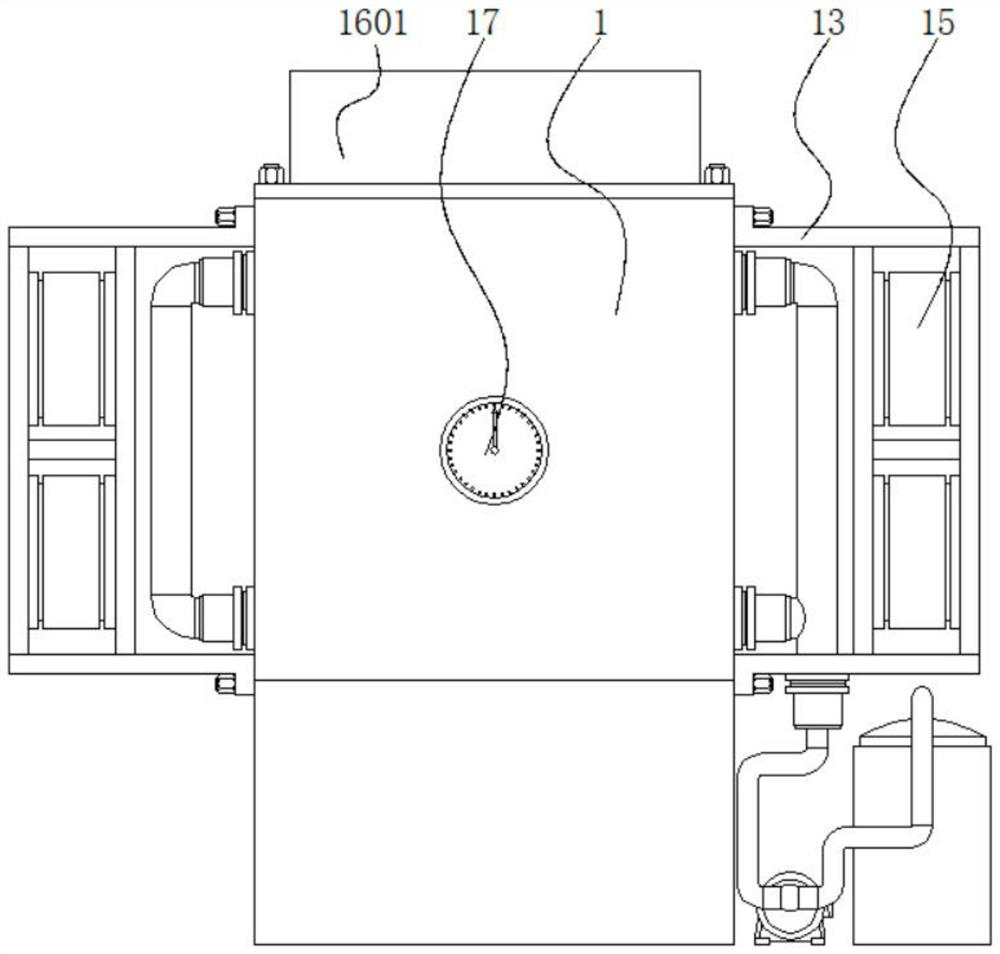

Compact energy-saving servo power unit

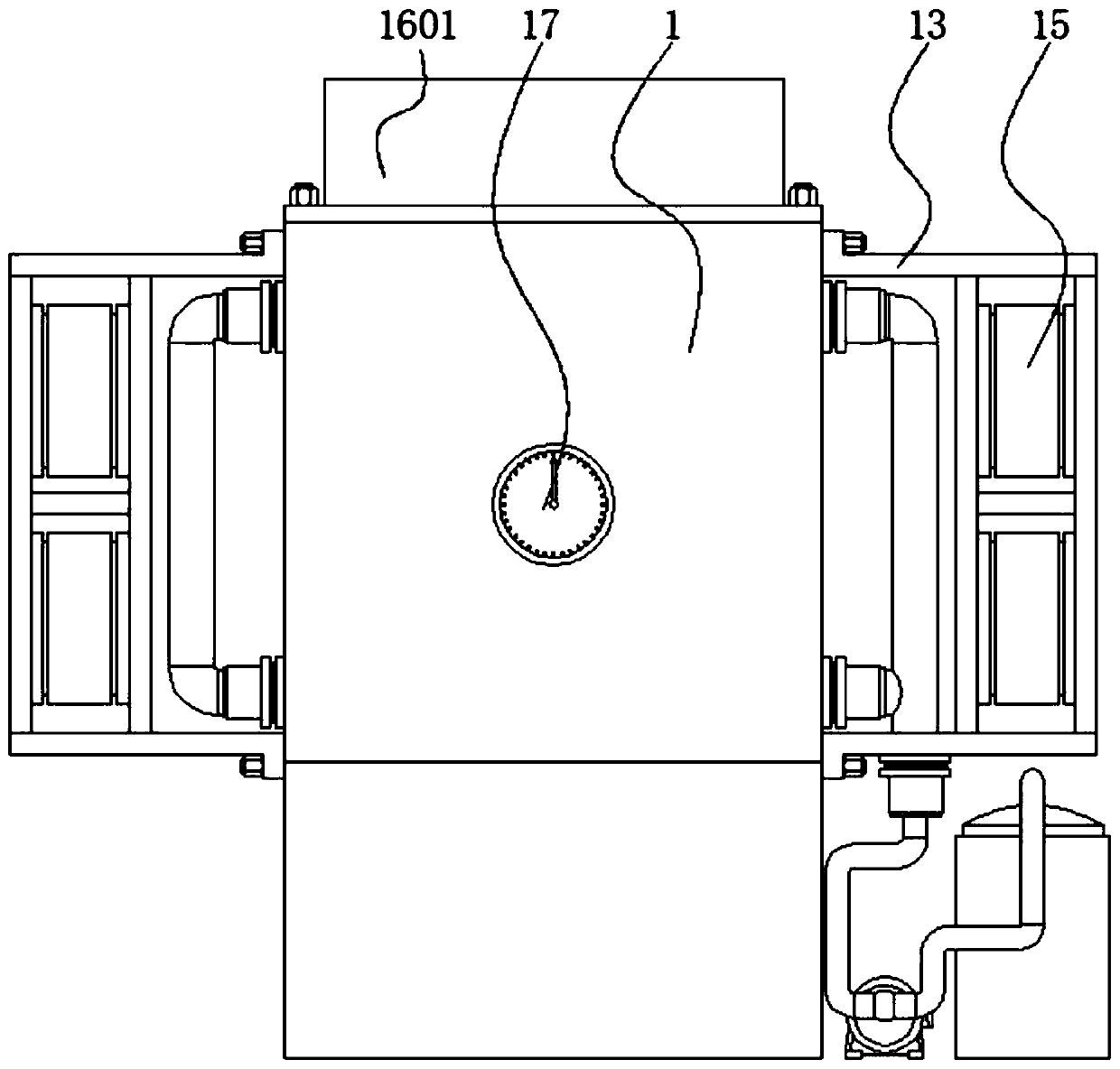

PendingCN111828414AFlow obstructionImprove cooling effectPump assembliesFluid-pressure actuator componentsOil canEngineering

The invention discloses a compact energy-saving servo power unit. The compact energy-saving servo power unit comprises an oil barrel, an oil inlet pipe, spur rings, a partition plate and water coolingpipes. An oil pump is arranged in an inner cavity of the oil barrel, and the oil pump is located at the circle center of the oil barrel. The oil inlet pipe communicates with the inner cavity of the oil barrel, an oil outlet of the oil inlet pipe is adjacent to an oil suction port of the oil pump and is separated from the oil suction port through the partition plate so that an arc-shaped flow pathcan be formed between the oil outlet of the oil inlet pipe and the oil suction port of the oil pump, and the water cooling pipes are arranged on the flow path. In the flow process of cooling oil withoil pressure, the cooling oil can constantly hit the inner cavity wall of the oil barrel due to centrifugal force, the multiple spur rings are arranged on the inner cavity wall of the oil barrel andarrayed into a layer in the longitudinal direction, the spur rings can puncture bubbles, the cooling oil is cooled under the action of the water cooling pipes, meanwhile, the water cooling pipes can hinder the flow of the cooling oil to prolong the stay time of the cooling oil in the inner cavity of the oil barrel, thus, the cooling oil entering the oil pump is sufficiently cooled, and bubble removal treatment of the cooling oil is also completed.

Owner:广东盈威流体控制技术股份有限公司

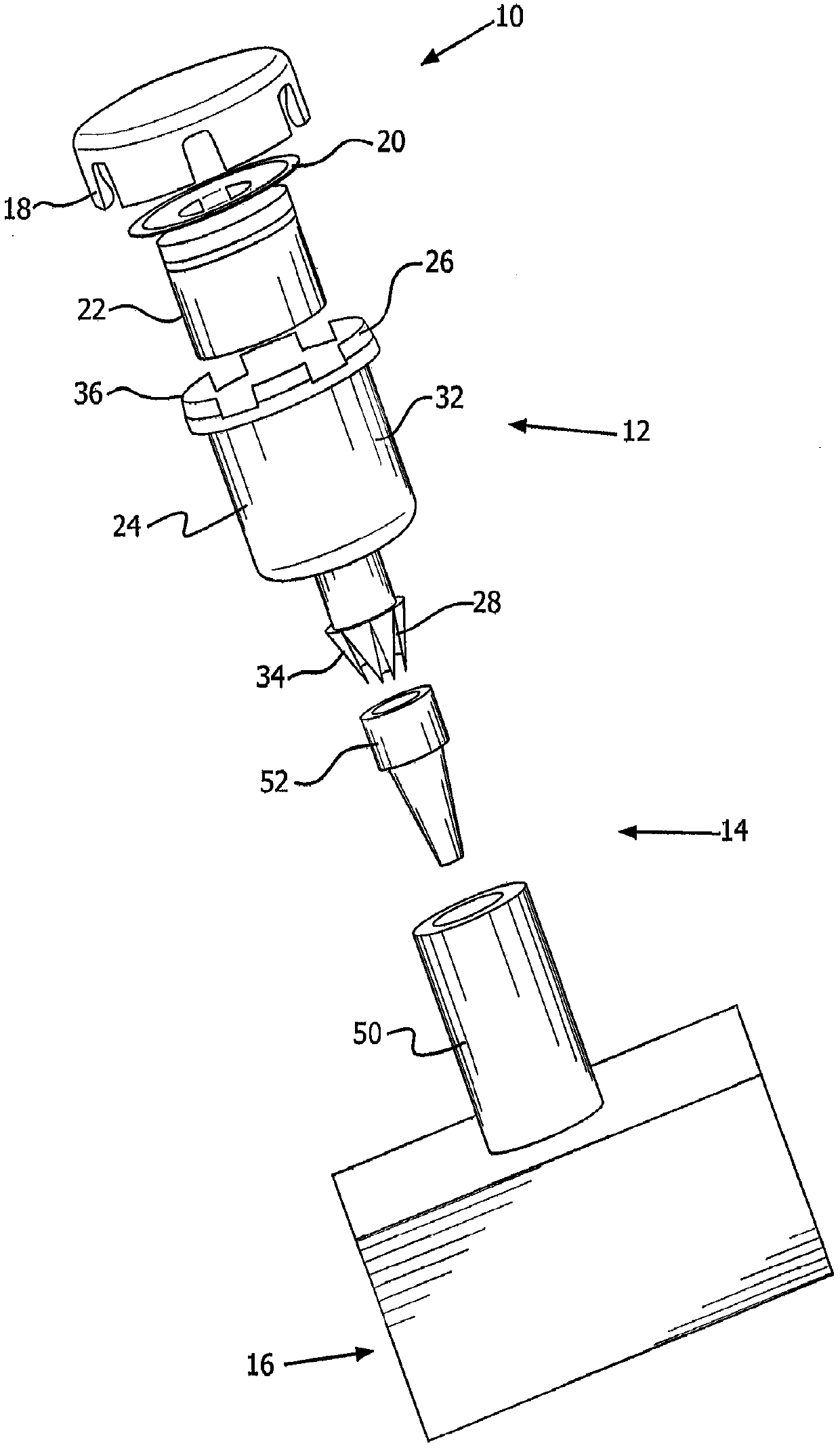

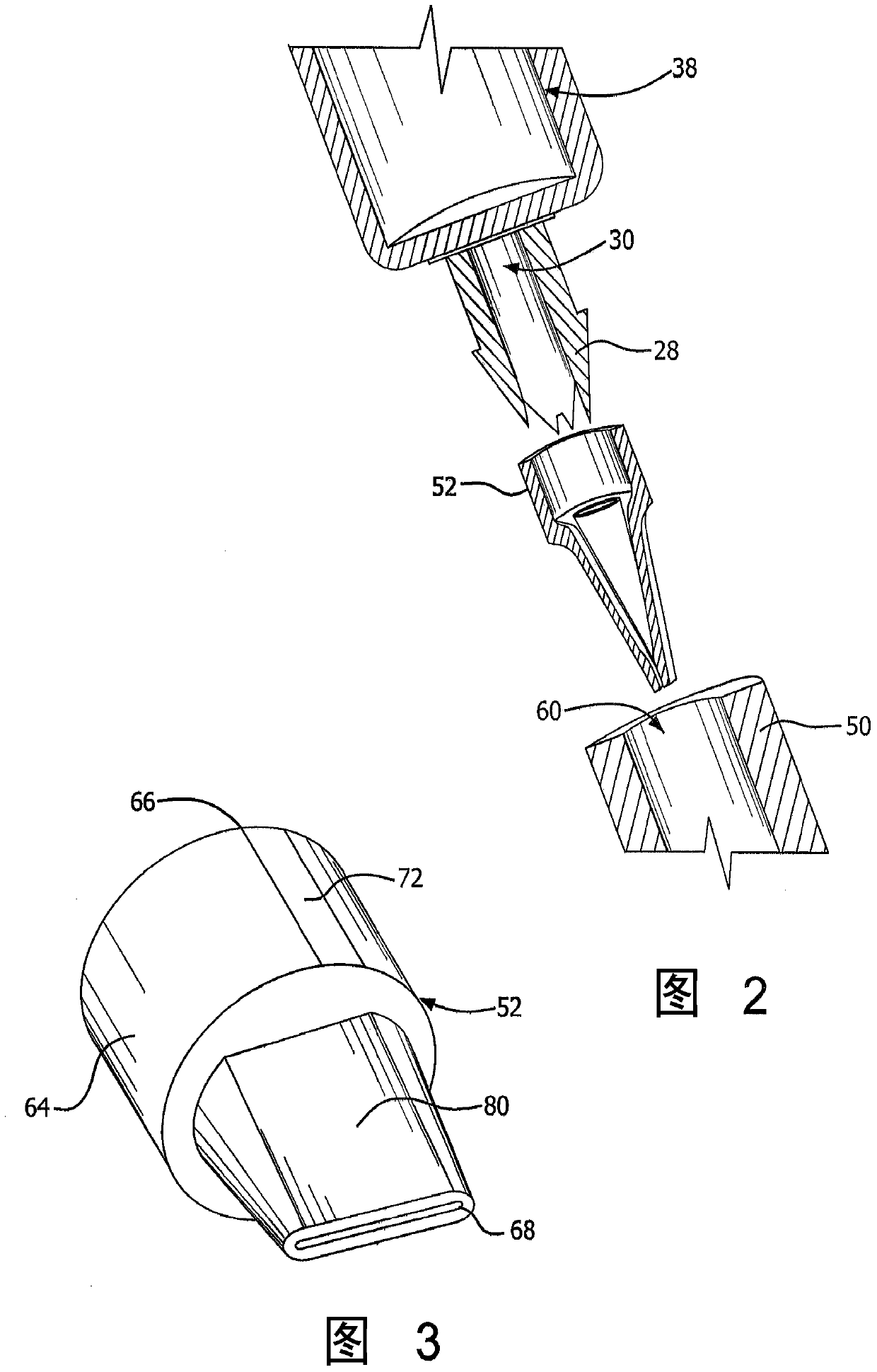

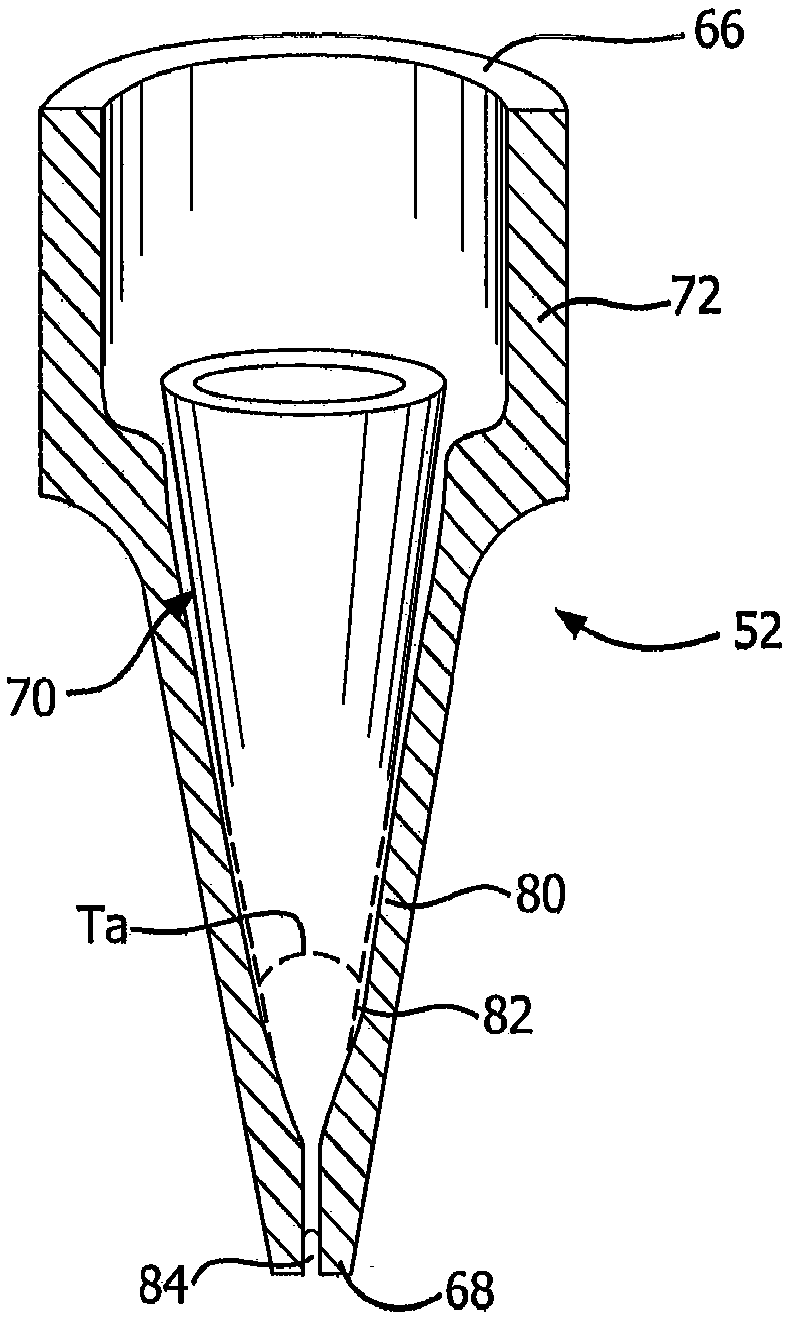

ventilation system

A ventilation system (10) for an enclosure (16) containing a liquid, the system comprising a ventilation module (12) including a housing defining a channel (30) and a flow control module (14) (24), a diaphragm (20) retained within the channel, and a sorbent (22) retained within the channel; the flow control module (14) is associated with the ventilation module and includes a valve (52) having an internal channel (70) , air can flow through the valve through the internal channel (70) in a first direction and a second opposite direction, wherein the flow control module (14) acts as a liquid to flow from the enclosure (16) towards the sorbent (22) through the valve (52) barrier pieces.

Owner:WL GORE & ASSOC INC

Hydro-pneumatic suspension damping system of underground multifunctional service vehicle

ActiveCN113790240AGuaranteed shock absorptionReduce flowSpringsGas and liquid based dampersSuspension (vehicle)Mechanical engineering

The invention disclose a hydro-pneumatic suspension damping system of an underground multifunctional service vehicle. The hydro-pneumatic suspension damping system comprises a connecting rod, a piston and a cylinder barrel, the peripheral side of the piston is in sliding sealing connection with the inner wall of the cylinder barrel, the lower side of the piston is connected with the upper end of the connecting rod, a partition plate located above the piston is fixed to the inner wall of the cylinder barrel, and a damping through hole is formed in the partition plate; a sliding rod penetrates through the damping through hole in a sliding and sealing mode, the lower end of the sliding rod is connected with the upper side of the piston, an inner sunken groove is formed in the peripheral side of the sliding rod in the length direction of the sliding rod, a guide deep groove is formed in the inner sunken groove in the length direction of the inner sunken groove, and a sliding inserting rod is installed in the guide deep groove in a sliding and sealing mode; and a liquid guide hole communicating the interior and exterior of the lower portion of the guide deep groove is formed in the peripheral side of the sliding rod. According to the hydro-pneumatic suspension damping system, different oil damping effects in the compression stroke and the recovery stroke are achieved, rapid resetting of the hydro-pneumatic suspension damping system in the recovery stroke is achieved, the amplitude of the compression stroke is guaranteed, the damping effect of the hydro-pneumatic suspension damping system is guaranteed, and the change of oil flowing damping caused by the fact that oil is pressed and heated is reduced.

Owner:QINGDAO FAMBITION HEAVY MASCH CO LTD

carburetor

ActiveCN104061090BAchieve compactnessMovement hindranceFloat-controlled apparatusMachines/enginesMarine engineeringFloat chamber

The invention provides a carburetor, and fluctuation of an oil level of a fuel in a float chamber without increasing the diameter of the float chamber. A floator (7) forms a shape of a major arc which surrounds a fuel boss (1a) and is open in a pivot (9) side, and an arc-shaped upper longitudinal rib (23) protruding downward from a lower outer peripheral edge of the floator (7) is formed on the floator (7); and, on the other hand, an arc-shaped lower longitudinal rib (25) is formed on the float chamber (5), and the lower longitudinal rib (25) is erected from the bottom of the float chamber (5) to the lower surface of the floator (7) and is disposed on the inner side of the upper longitudinal rib (23).

Owner:HITACHI ASTEMO LTD

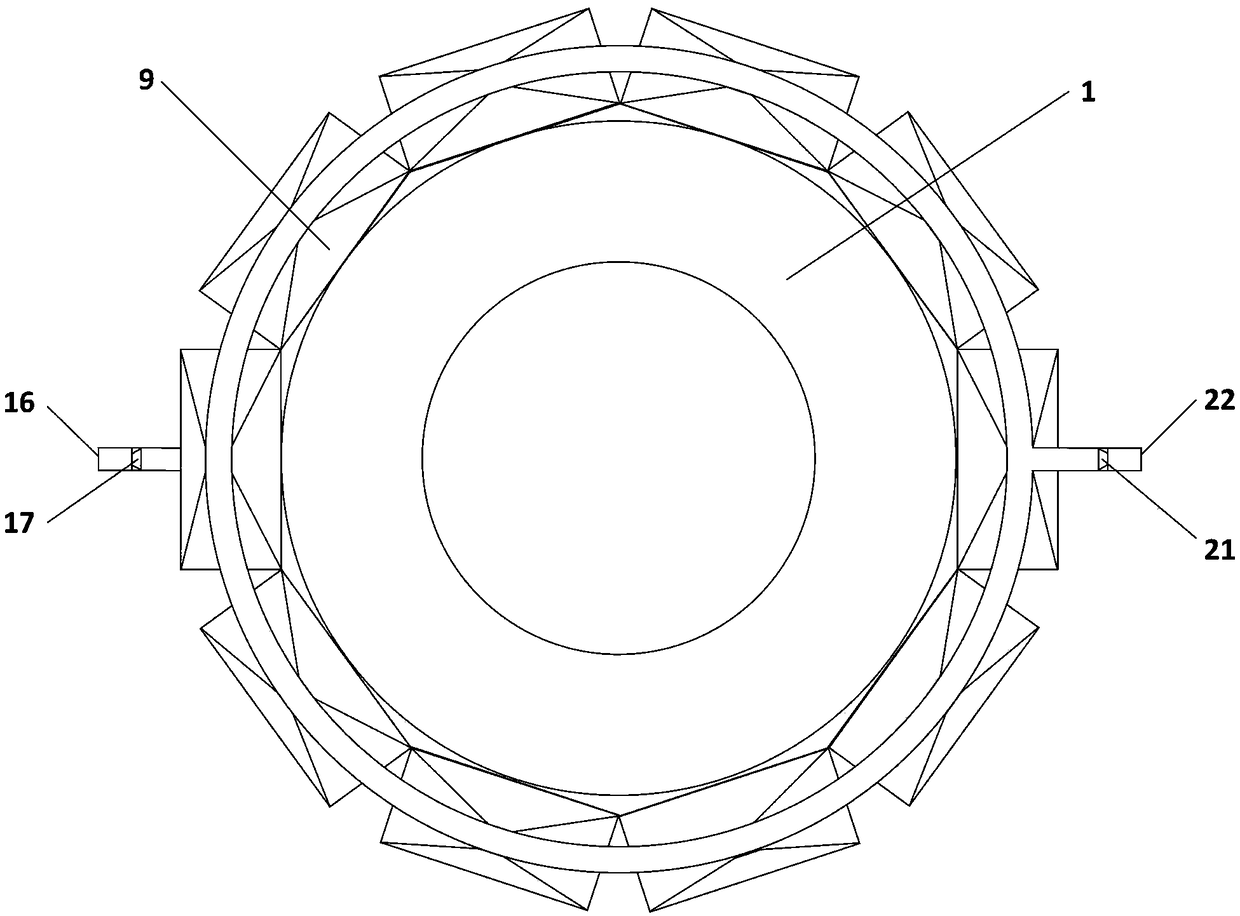

A flue gas desulfurization device and method

ActiveCN107126815BImprove desulfurization efficiencyIncreased persistenceGas treatmentDispersed particle separationThermodynamicsFlue gas

The invention relates to a device and a method for desulfurizing flue gas. The device and the method have the advantages that a rotary impeller structure containing adsorbing material is applied into a cavity of a desulfurizing device, the adsorbing catalyzing and separation of sulfur dioxide in the flue gas can be simultaneously and continuously performed, and the desulfurizing efficiency and continuity are greatly improved; a desulfurizing impeller is made of heat insulation material, the tail end of the impeller is tightly connected with a casing, the reverse flowing of flue gas and clean fluid promotes the clockwise rotation of the desulfurizing impeller, the direct contact between the flue gas and the clean liquid is avoided, the loss of flue gas residual heat in the desulfurizing process is avoided, the obstacle of flue gas flowing in the desulfurizing process is avoided, and the power consumption in the desulfurizing process is decreased to a greater extent; in the clockwise rotation process of the desulfurizing impeller, the flowing of flue gas and clean gas simultaneously generates certain pushing function, and the rotation energy consumption of the impeller is decreased.

Owner:XI AN JIAOTONG UNIV

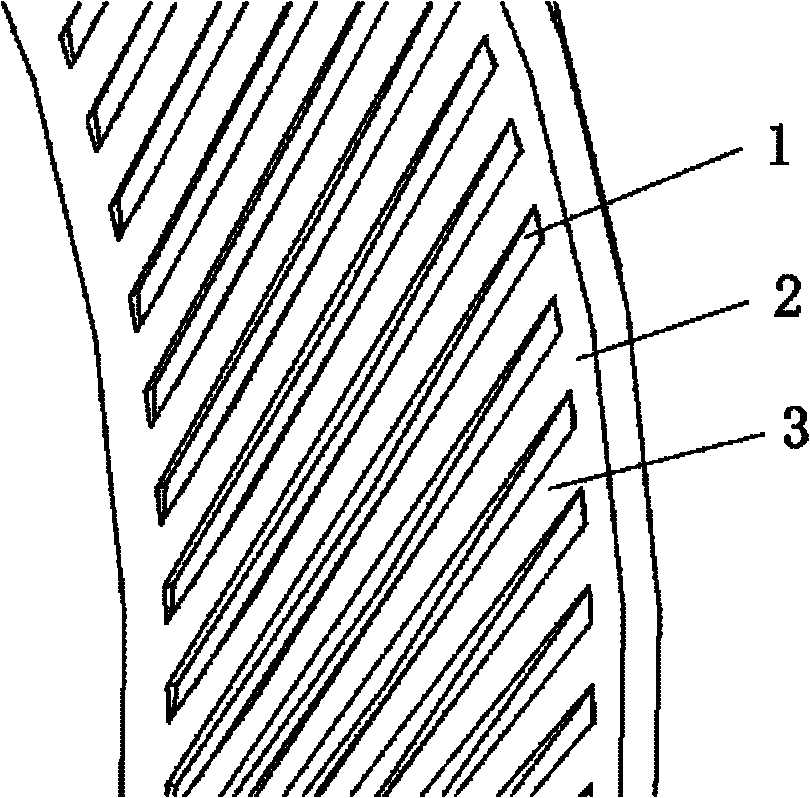

Piston for internal combustion engine

InactiveCN103210198AReduce lossExtended service lifePlungersMachines/enginesCounter pressureEngineering

The present invention relates to a piston (10) for an internal combustion engine, comprising a piston head (11) and a piston skirt (15) delimited by a lower skirt edge (18), wherein the piston skirt (15) comprises a running surface (16) associated with the pressure side (DS) of the piston skirt and a running surface (17) associated with the counter-pressure side (GDS) of the piston skirt and a zone (21, 21') is associated with each of the two running surfaces (16, 17), which zone starts from the lower skirt edge (18) and is exposed to a maximum load during the operation of the internal combustion engine. According to the invention, the zone (21) of the running surface (16) associated with the pressure side (DS) and / or the zone (21') of the running surface (17) associated with the counter-pressure side (GDS) is provided with a coating (23, 23') which has vertically extending grooves (24, 24').

Owner:MAHLE INT GMBH

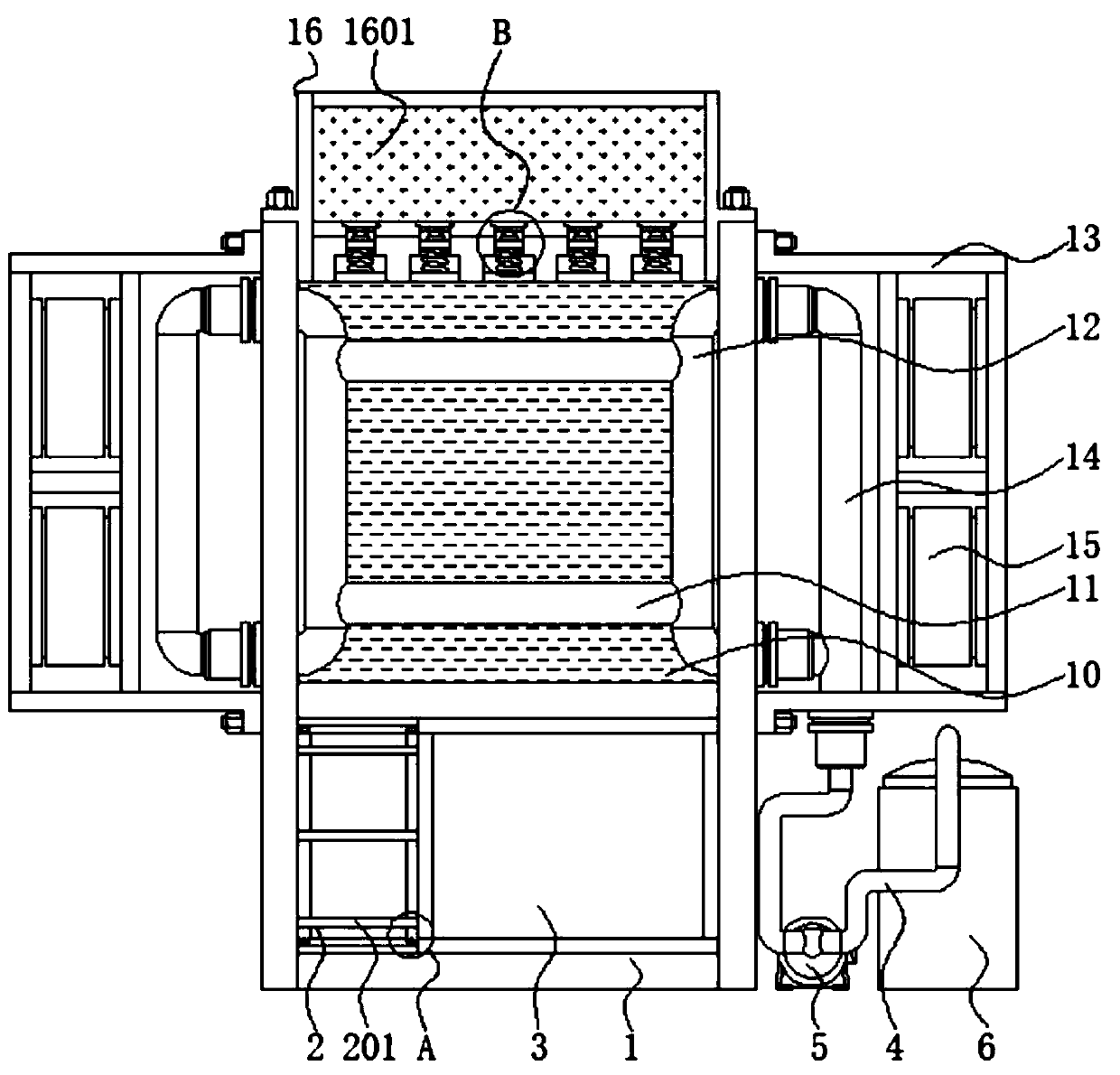

Power supply apparatus for vehicle

ActiveCN102820439BGuaranteed rigidityFlow obstructionCell temperature controlElectric propulsion mountingComputer moduleCoolant

A power supply apparatus includes a plurality of battery modules, a support plate, a plurality of first reinforcing projections, and a plurality of second reinforcing projections. The support plate supports the battery modules and includes a first plate and a second plate. The first plate thermally contacts bottom surfaces of the battery modules. The second plate is placed on a bottom surface of the first plate to define cooling spaces between the first and second plates. A coolant is to flow in the cooling spaces. The plurality of first reinforcing projections is provided on at least one of the first and second plates. The first reinforcing projections project into the cooling spaces and extend in a first direction. The plurality of second reinforcing projections is provided on a top surface of the first plate and extending in a second direction intersecting with the first direction.

Owner:HONDA MOTOR CO LTD

A self-cleaning flue gas dust removal device and method

ActiveCN107158819BImprove dust removal efficiencyFlow obstructionDispersed particle filtrationImpellerFlue gas

Self-cleaning flue gas dust removal apparatus and method. A multi-hole impeller structure is used in a chamber of the dust removal apparatus, so that adsorption and separation of pollutant particles in flue gas are carried out independently, and further dust removal efficiency is greatly increased; meanwhile, a dust removal impeller is made from heat-insulating materials, wherein the end of the impeller is tightly connected to a shell body, so that direct contact between the flue gas and a cleaning fluid is avoided since the flue gas and the cleaning fluid flow in opposite directions for promoting the clockwise rotation of the dust removal impeller, thereby avoiding loss of residual heat in the flue gas during dust removal and avoiding that the dust removal obstructs flowing of the flue gas, so that power consumption during the dust removal process is reduced more. During the clockwise rotation of the dust removal impeller, the flowing of the flue gas and the cleaning fluid also has certain promoting effect, so that the power consumption during rotation of the impeller is reduced. The apparatus is high in dust removal efficiency, is low in manufacturing and operation cost and is wide in applicable temperature range.

Owner:XI AN JIAOTONG UNIV

An oil channel dredging device for vegetable oil transformer

ActiveCN111029089BReduce wearEasy to pull outTransformers/inductances coolingTransformers/inductances casingsWater storageVegetable oil

The invention discloses an oil passage dredging device for vegetable oil transformers, relates to the technical field of vegetable oil transformers, in particular to an oil passage dredging device for vegetable oil transformers, which includes a transformer main body and a fire extinguishing mechanism. There is a storage mechanism, and a control box is installed on one side of the storage mechanism, an outlet pipe is installed on one side of the bottom of the transformer body, and a water pump is installed in the middle of the outlet pipe, and a water storage is installed on one side of the outlet pipe. tank, and the interior of the water storage tank is provided with a first partition, a second partition is installed on one side of the first partition, and a stainless steel filter is installed above the second partition, and above the control box An oil storage chamber is installed, and a connecting pipe is arranged inside the oil storage chamber. The oil channel dredging device for the vegetable oil transformer is provided with a temperature detector, which can effectively detect and process the temperature of the vegetable oil inside the oil storage chamber, and provide intuitive data prompts for the operator.

Owner:武汉天仕达电气有限公司

heat sink

ActiveCN110785071BReduce thermal resistanceImprove cooling efficiencySemiconductor/solid-state device detailsSolid-state devicesInterior spaceWorking fluid

Owner:FURUKAWA ELECTRIC CO LTD

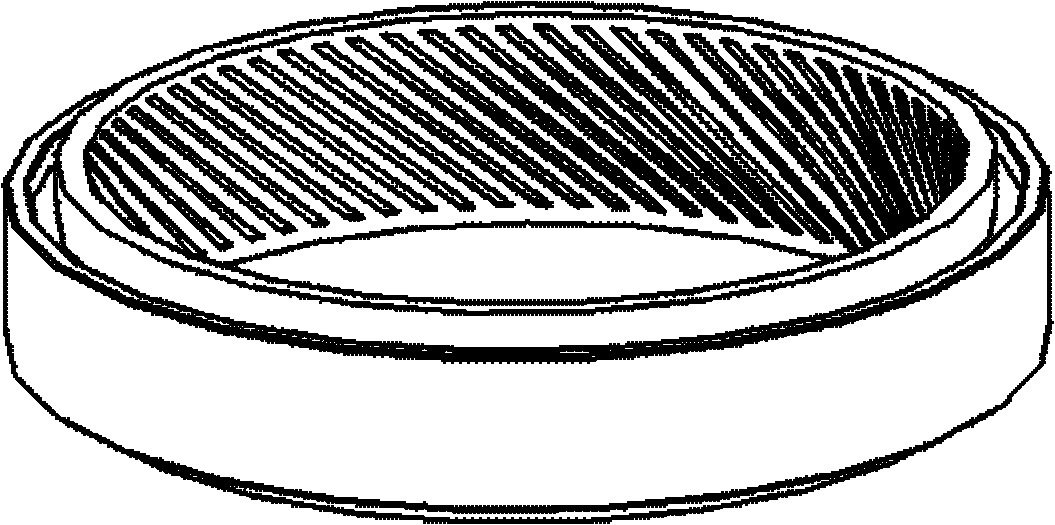

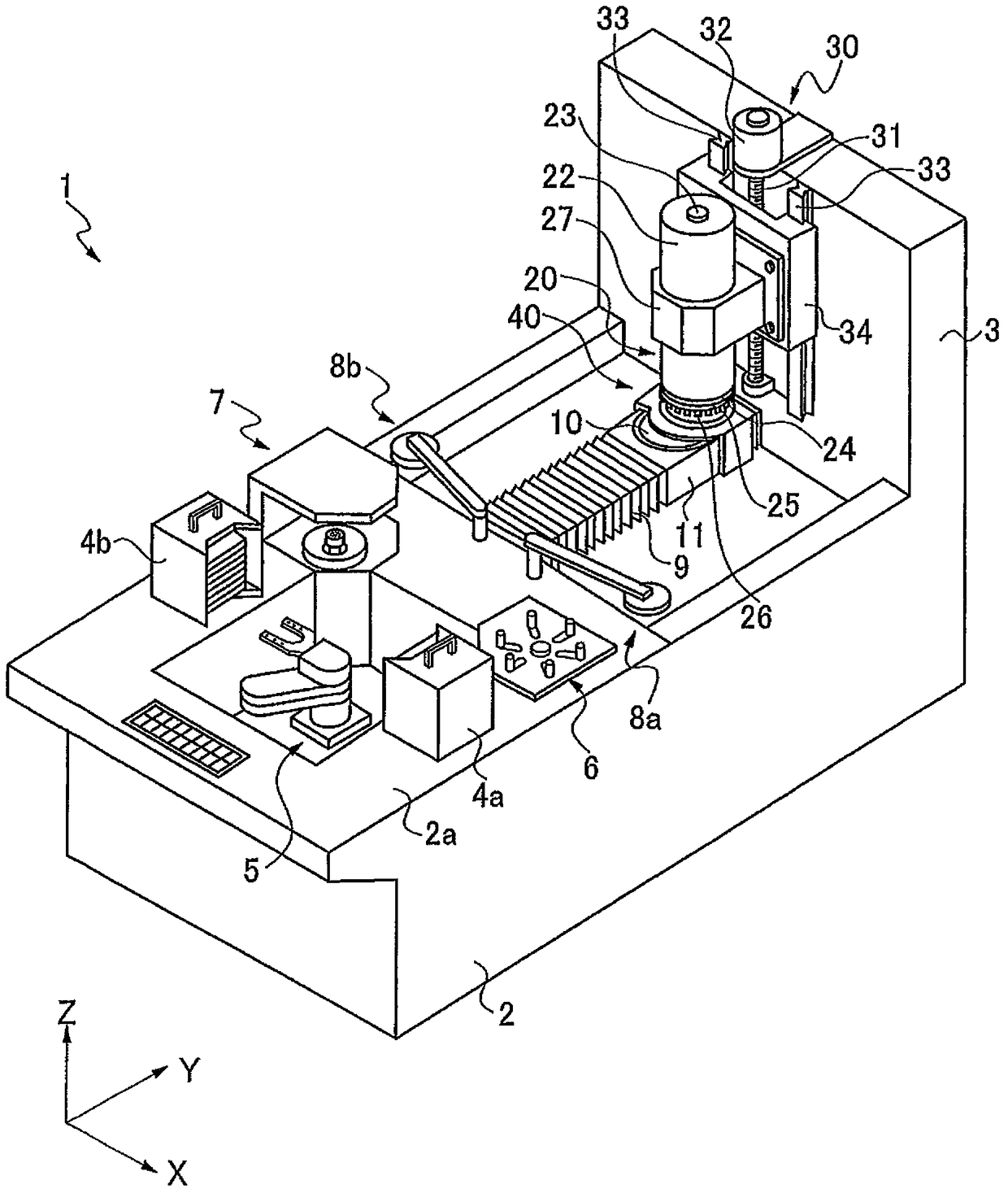

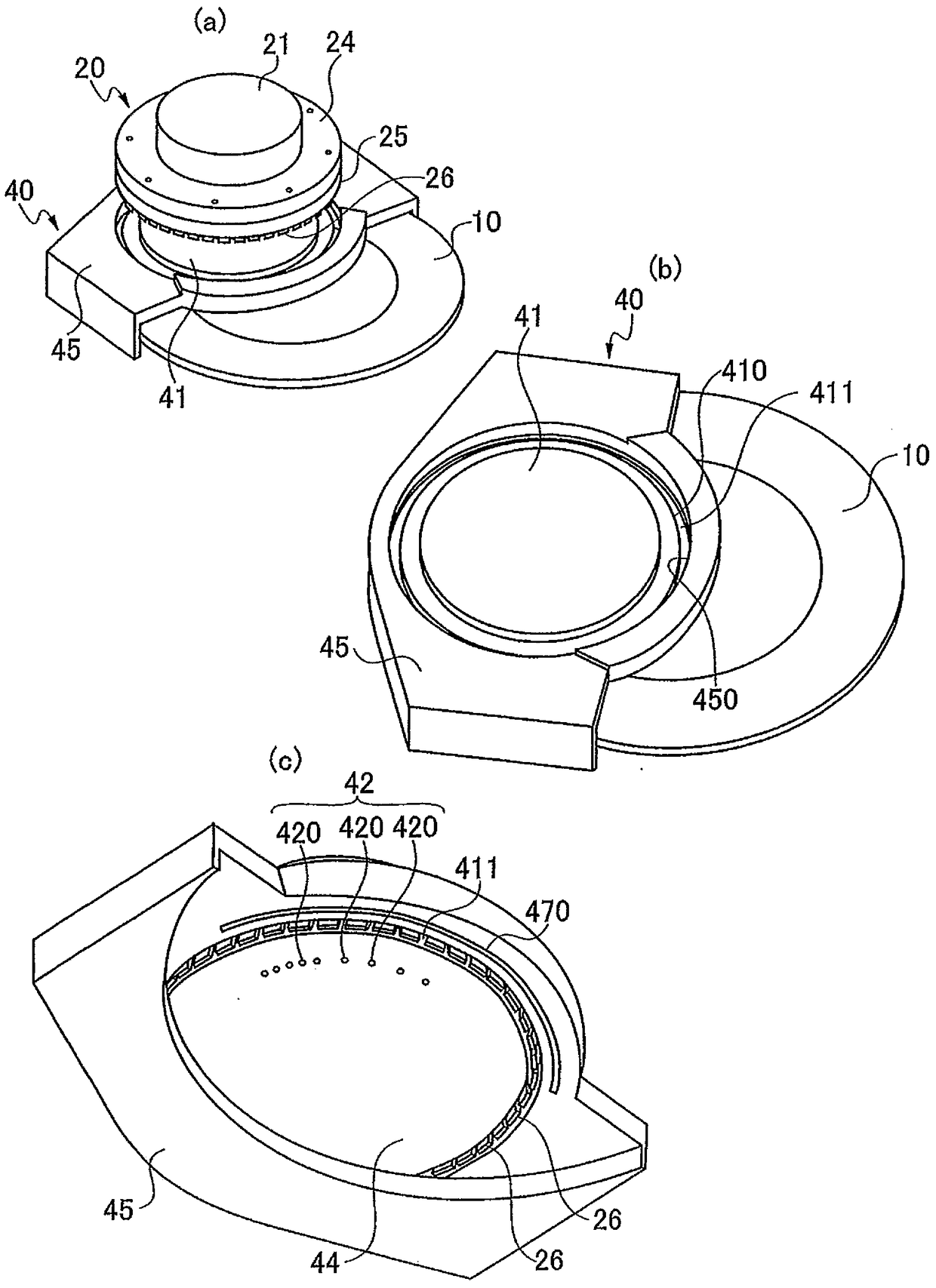

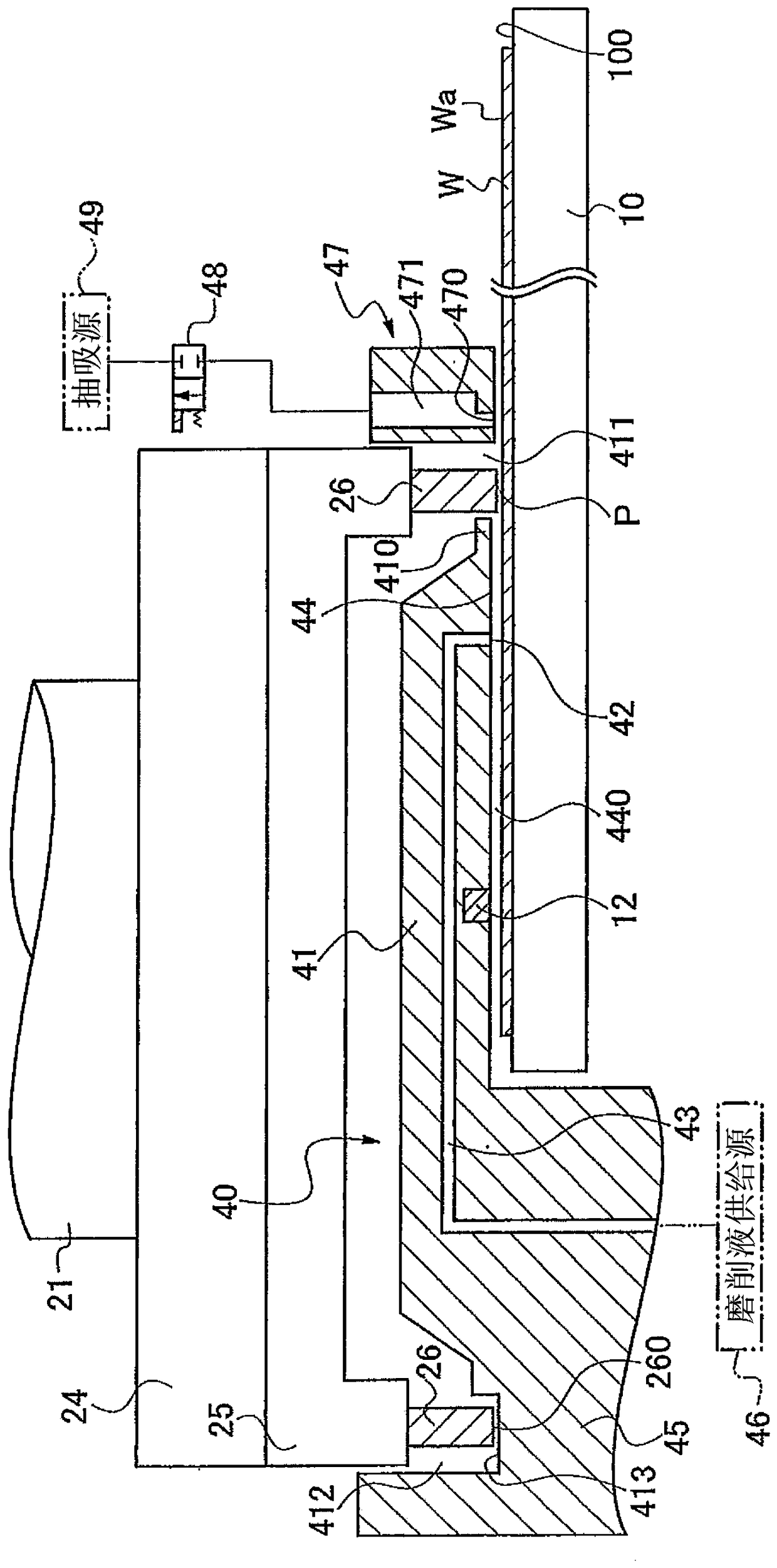

Grinding device

ActiveCN105081980BFlow obstructionEfficient supplyGrinding/polishing apparatusEngineeringFluid supply

A subject of this invention is to provide a grinding device that provides a more effective way to supply grinding fluid to a processing area as compared to a conventional method. The grinding device includes a holding platform that holds a to-be-processed object, a grinding mechanism that grinds the to-be-processed object held in this way and a grinding fluid supplying means that supplies grinding fluid to the to-be-processed object and a grinding stone. The grinding fluid supplying means includes a grinding fluid supplying port and an upper wall section. The grinding fluid supplying port supplies the grinding fluid onto an upper surface of the to-be-processed object from a position closer to a rear side of a rotating direction of the holding platform than a processing area where the to-be-processed object is processed by the grinding stone. The upper wall section, which is set between the grinding fluid supplying port and the grinding stone in the processing area and has predetermined intervals with respect to the upper surface side of the to-be-processed object, makes the grinding fluid flow while the holding platform is rotating to form a grinding fluid supplying layer around the processing area. As a result, the grinding fluid supplying layer can be used to shield a gas layer generated around the grinding stone in rotation to thereby effectively supply the grinding fluid to the processing area.

Owner:DISCO CORP

Oil duct dredging device for vegetable oil transformer

ActiveCN111029089AReduce wearEasy to pull outTransformers/inductances coolingTransformers/inductances casingsWater storageVegetable oil

The invention discloses an oil duct dredging device for a vegetable oil transformer, relates to the technical field of vegetable oil transformers, and particularly relates to an oil duct dredging device. The device comprises a transformer body and a fire-extinguishing mechanism, a storage mechanism is arranged in the transformer main body; a control box is mounted on one side of the storage mechanism; a water outlet pipe is mounted on one side of the bottom of the transformer body; a water pump is installed in the middle of the water outlet pipe, a water storage tank is installed on one side of the water outlet pipe, a first partition plate is arranged in the water storage tank, a second partition plate is installed on one side of the first partition plate, a stainless steel filter screenis installed above the second partition plate, an oil storage chamber is installed above the control box, and a connecting pipe is arranged in the oil storage chamber. The oil duct dredging device forthe vegetable oil transformer is provided with a temperature detector, the temperature of vegetable oil in the oil storage chamber can be effectively detected and processed through the temperature detector, and visual data prompts are provided for operators.

Owner:武汉天仕达电气有限公司

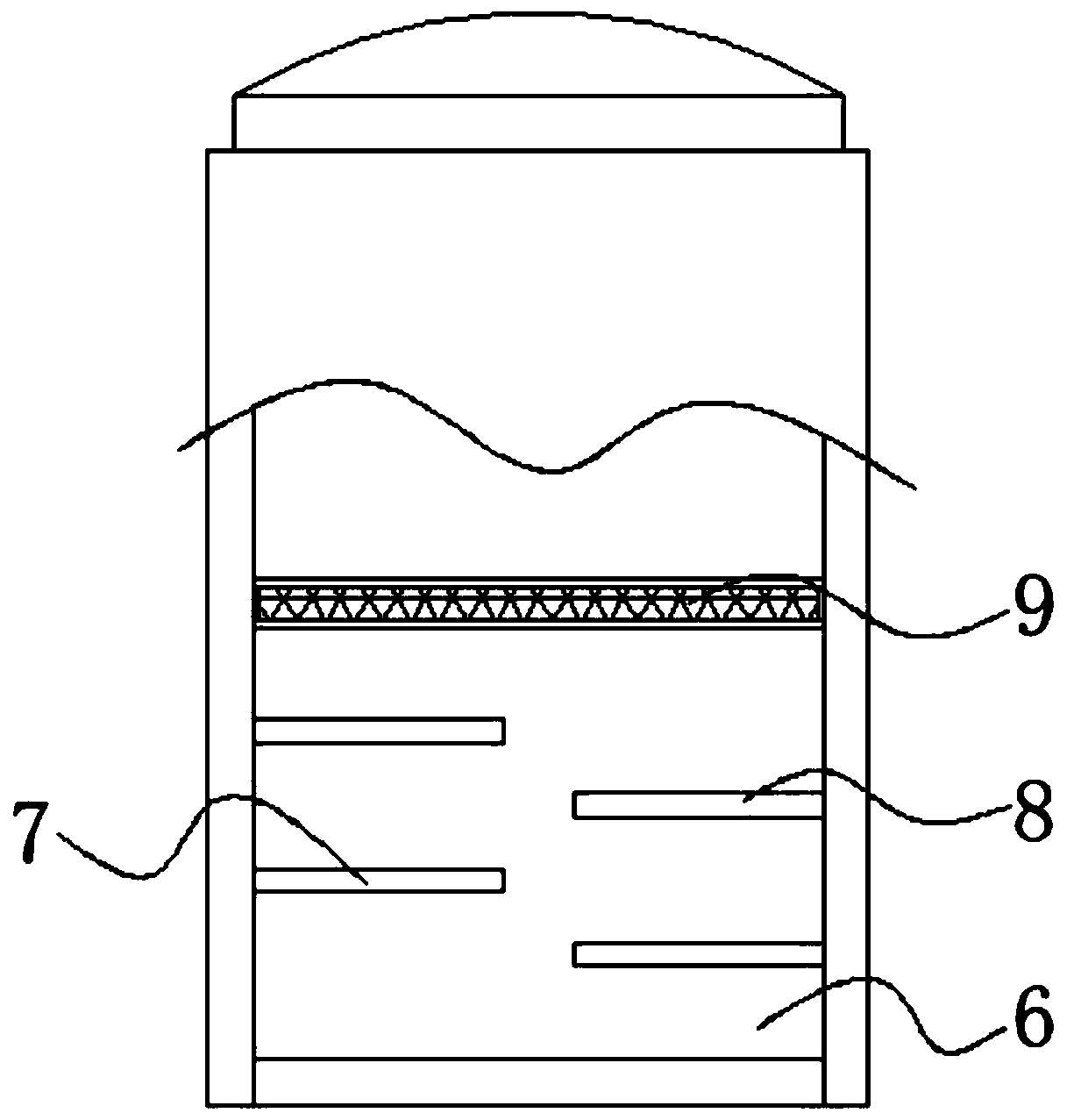

Self-circulation flue gas dedusting and cooling tower and method

ActiveCN107198924ARealize self-circulation functionImprove dust removal effectCombination devicesGas treatmentImpellerCooling tower

The invention discloses a self-circulation flue gas dedusting and cooling tower and a method. A porous impeller structure is applied into a dedusting device cavity, potential energy of water in the cooling tower is fully utilized to act to flow from top to bottom to drive a dedusting impeller to rotate clockwise, extra acting is avoided, and a self-circulation function is achieved; meanwhile, a flushing effect of the water in the cooling tower is fully utilized, a dedusting effect is well achieved, filtering of a filter screen can guarantee that circulation water can be recycled; a certain promoting effect on flue gas flowing into in an impeller rotating process is achieved; adsorption and flushing on pollutant particles in the flue gas can be separately performed by the porous impeller structure, so that dedusting efficiency is obviously improved; reversed flowing of the flue gas and water is utilized to drive the dedusting impeller to rotate clockwise, the flue gas is prevented from directly contacting the water, waste heat loss of the flue gas in a dedusting process is avoided; meanwhile, the flue gas is not prevented from flowing in the dedusting process, and power consumption in the dedusting process is reduced to a larger extend.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com