A kind of self-circulating flue gas dust removal cooling tower and method

A cooling tower and flue gas technology, applied in the direction of separation methods, water shower coolers, chemical instruments and methods, etc., can solve the problems of low dust removal efficiency, high dust removal efficiency, and high operating costs, achieve good dust removal effect, and avoid flue gas The loss of waste heat and the effect of reducing pump power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

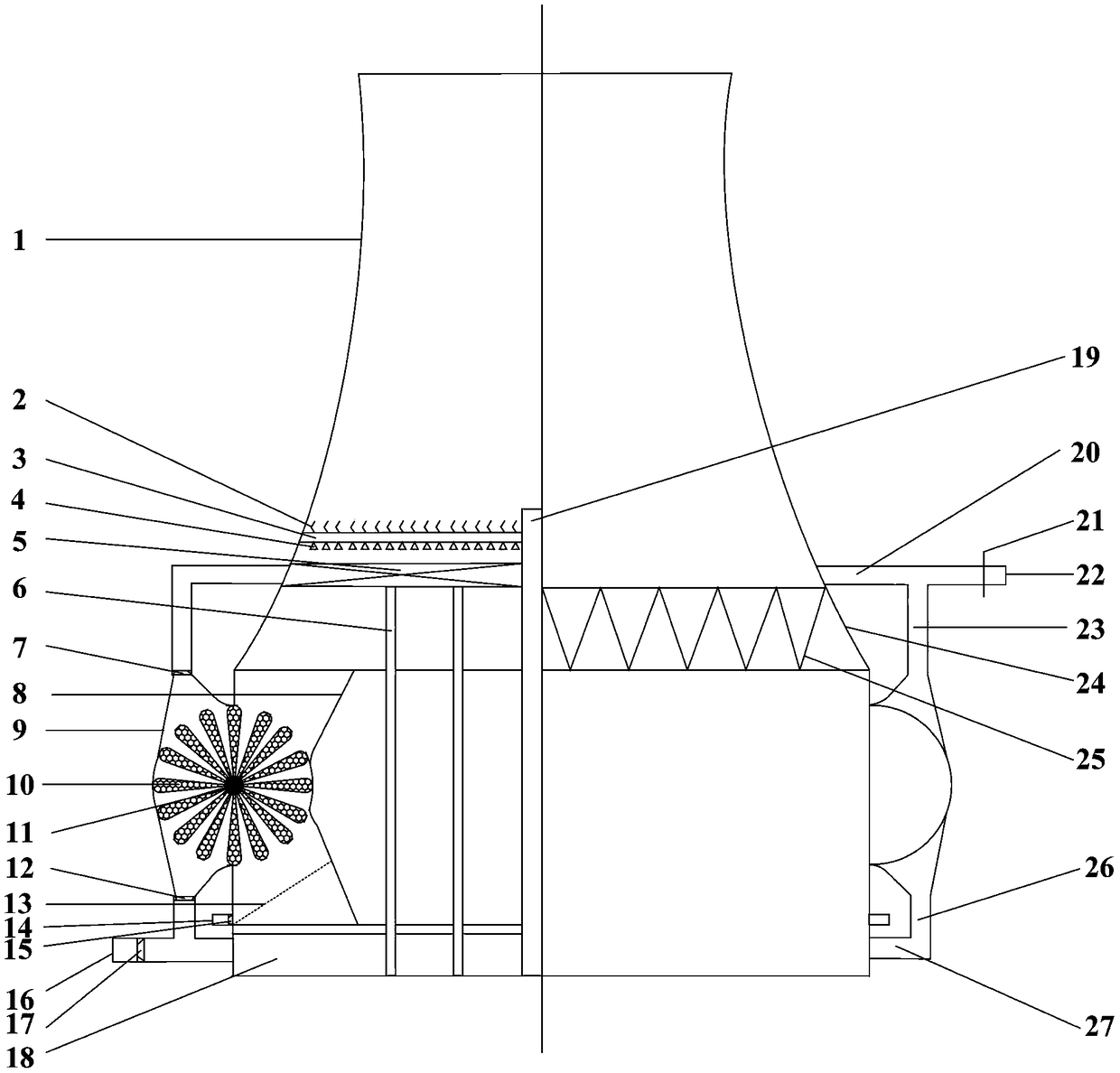

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

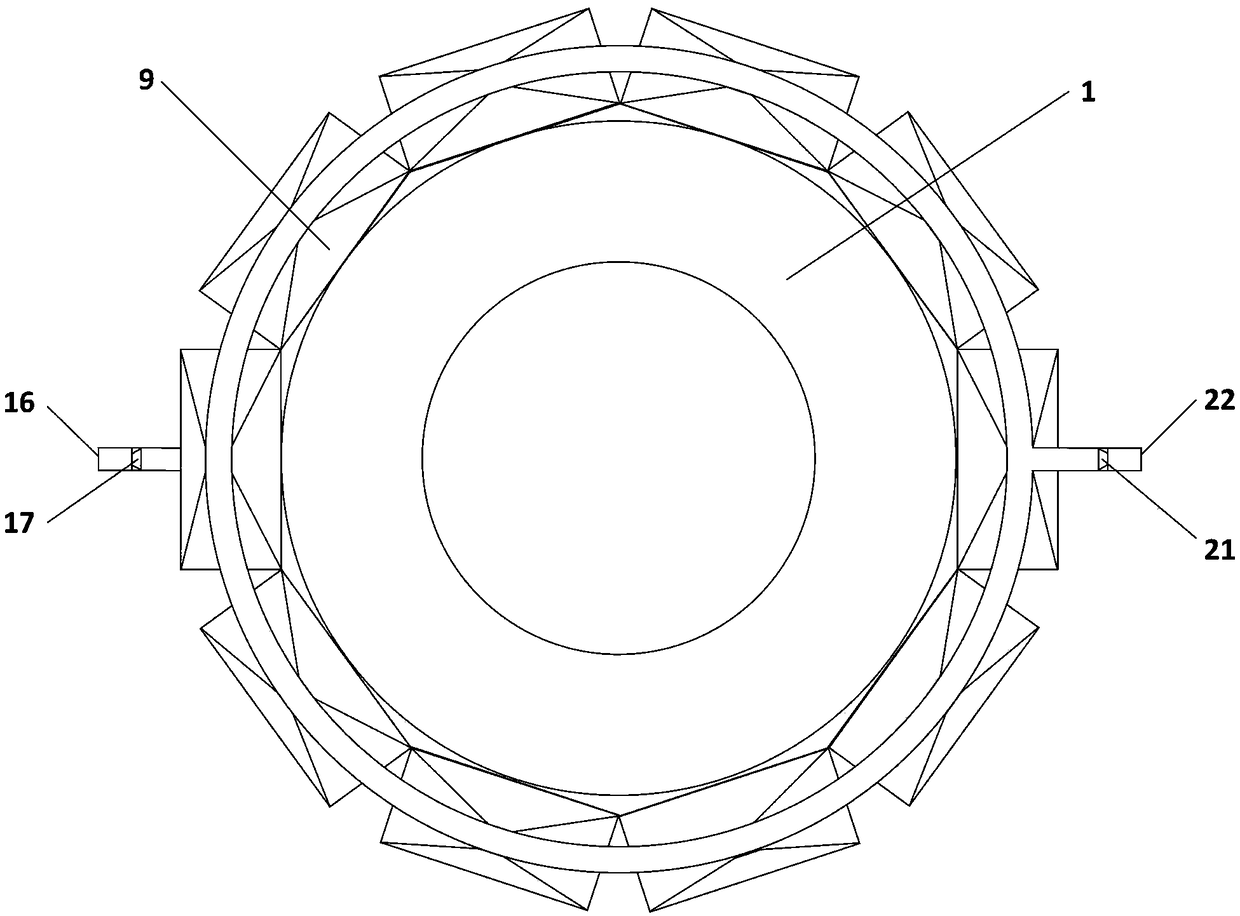

[0032] see figure 1, 2. The present invention includes a cooling tower body and a tower 1 with a hyperbolic shape arranged on the cooling tower body. In the tower 1, a water eliminator 2, a water distribution pipe 3, a nozzle 4 and a filler 5 are sequentially arranged from top to bottom. , the filler 5 should have the functions of increasing heat dissipation, prolonging the residence time of cooling water, increasing heat transfer area, increasing heat transfer, and uniform water distribution. Type sine wave packing, point wave packing, hexagonal honeycomb packing, two-way wave packing, oblique wave packing. The lower end of the filler 5 is provided with a cooling tower air inlet 24 and a herringbone column 25, and a sump 18 is provided at the bottom of the cooling tower body, and a central shaft 19 is vertically provided at the center of the cooling tower b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com