Universal inner wall corrosion prevention and film forming device for bent and straight pipes

A film-forming device and straight-pipe technology, which can be used in devices for coating liquids on surfaces, pre-treatment surfaces, coatings, etc., and can solve problems such as spraying corrosion inhibitors, using hard-to-bend pipes, and hard-coating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

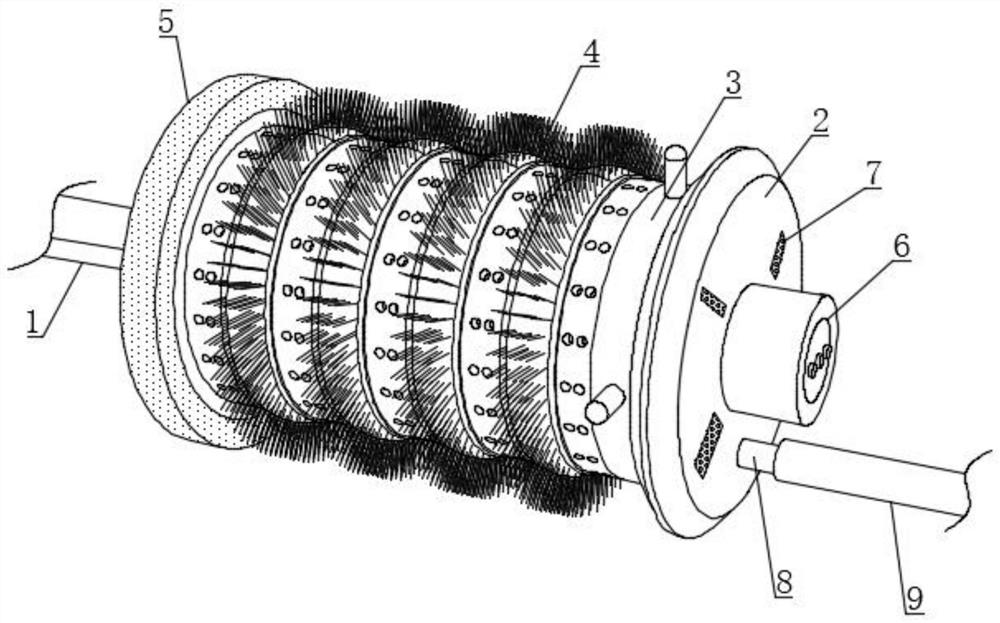

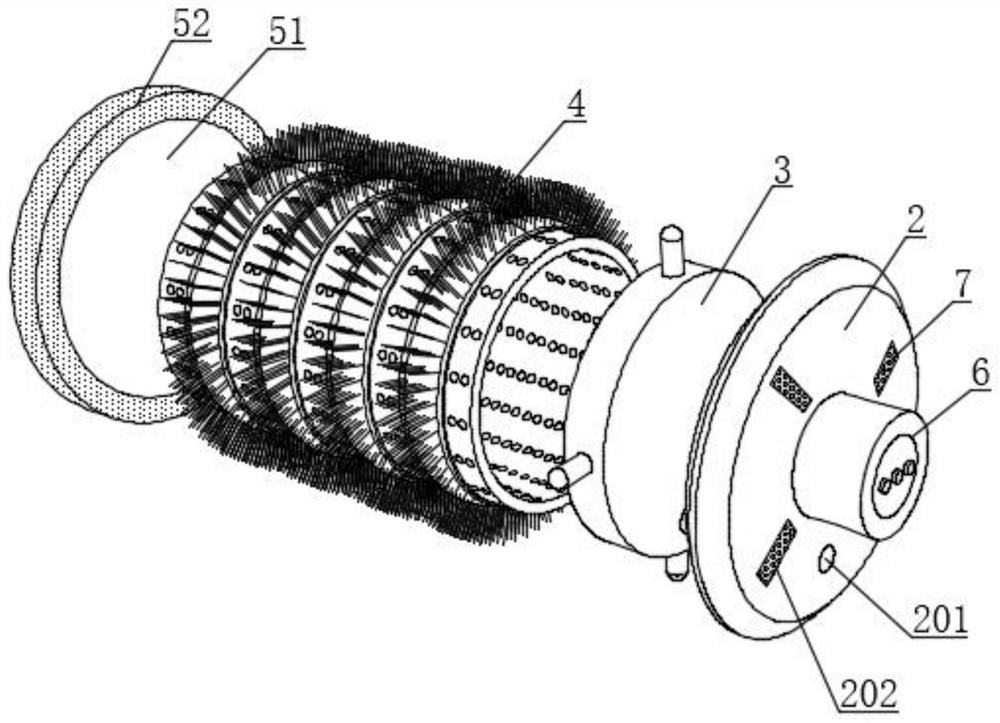

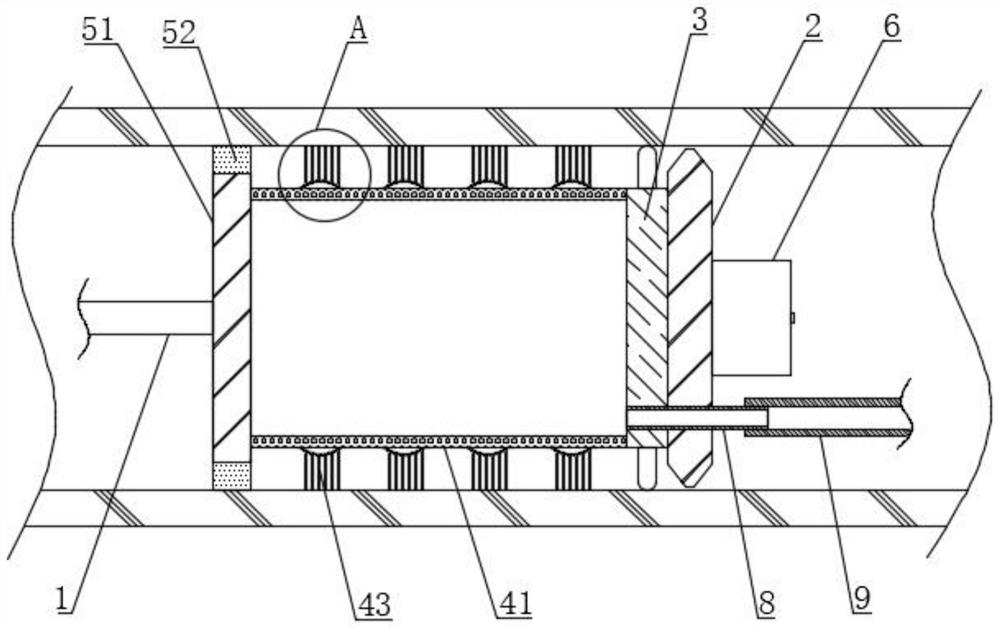

[0043] see figure 1 with figure 2 , a universal inner wall anti-corrosion film forming device for curved and straight pipes, comprising a scraper 2 and a sealing plate 5, a positioning plate 3 is fixedly connected to the end of the scraper 2 close to the sealing plate 5, and a positioning plate 3 is fixedly connected between the sealing plate 5 and the positioning plate 3 For internally adapted applicator tubes, see image 3 with Figure 4 , the inner adaptive application pipe includes a rubber hose 41 fixedly connected between the scraper 2 and the sealing plate 5, and the rubber hose 41 is provided with a plurality of evenly distributed overflow holes, and the corrosion inhibitor inside the rubber hose 41 can be Enter between the rubber hose 41 and the inner wall of the pipe through the overflow hole, and fully contact with the inner wall of the pipe. Through the use of the rubber hose 41, this device can be applied to straight pipes and irregular curved pipes at the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com