A kind of heat-resistant foam gel and its preparation method and application

A foam gel and foaming agent technology, applied in chemical instruments and methods, drilling compositions and other directions, can solve the problems of foam gel burst, inability to block formation, poor stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Embodiment 1, research on compatibility of gel system and foaming agent

[0058] Add different concentrations (0.1wt%, 0.2wt%, 0.3wt%, 0.4wt%, 0.5wt%) of sodium α-alkenyl sulfonate in the crosslinking agent A gel system and crosslinking agent B gel system (AOS), Cocamidopropyl Betaine (CAB-35), Sodium Dodecyl Sulfate (SDS), Sodium Dodecyl Sulfonate (SLS), Sodium Dodecylbenzene Sulfonate (SDBS), Explore the compatibility of the foaming agent with the cross-linking agent B gel system and the cross-linking agent A gel system, and use the GSC method to observe the gel system at 80°C and 10000mg / L NaCl salinity for 3 hours. The results are shown in Table 2.

[0059] It can be seen from Table 2 that with the increase of the amount of AOS, the gel strength of the cross-linking agent A gel system gradually decreased in 3 hours. When the amount of AOS was 0.1wt% and 0.2wt%, compared with the blank control, the AOS There is no obvious effect on the cross-linking agent A gel sys...

Embodiment 2

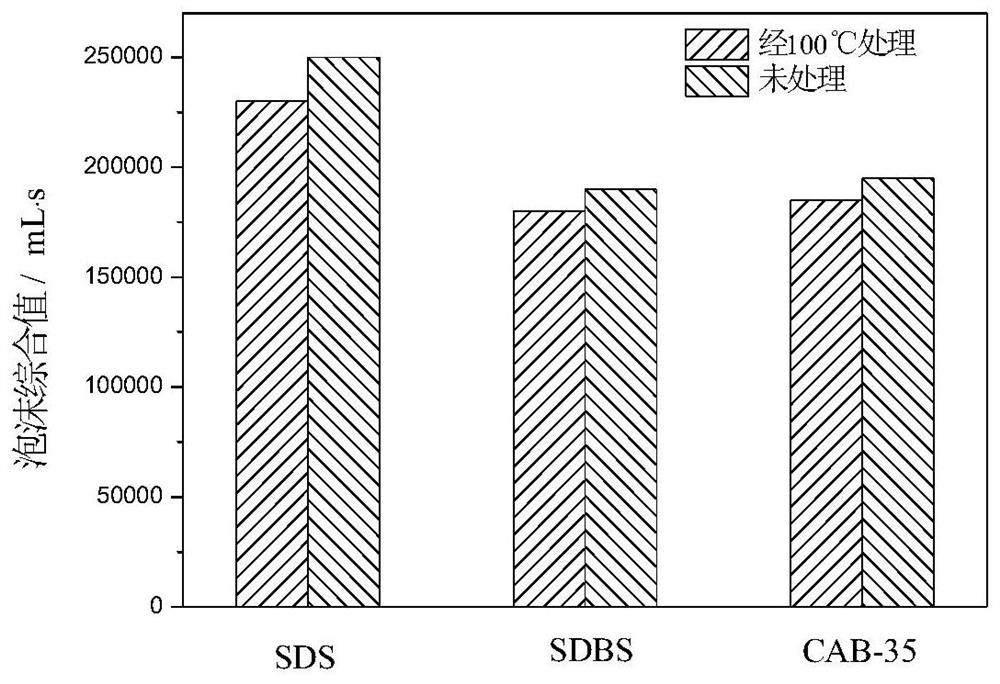

[0066] Embodiment 2, foaming agent temperature resistance evaluation

[0067] Prepare 100 mL of a foaming agent solution with a certain concentration and seal it in an oven at 100°C for 48 hours. Take it out and cool it to room temperature. Use a Waring-Blender stirrer at a speed of 6000r / min to stir for 120s to foam. The gas medium is air. The foaming ability and foam stabilizing ability of the foaming agent after high temperature treatment were measured, and compared with the performance of the foaming agent of the same concentration without high temperature treatment, in order to investigate the temperature resistance of the foaming agent. The foam comprehensive value changes of high temperature treated and untreated SDS, SDBS, CAB-35 are as follows: figure 1 shown.

[0068] Depend on figure 1 It can be seen that SDS has good foaming ability and foam stabilizing ability, and after heat treatment, the foam comprehensive value drops the most; the foaming ability and foam st...

Embodiment 3

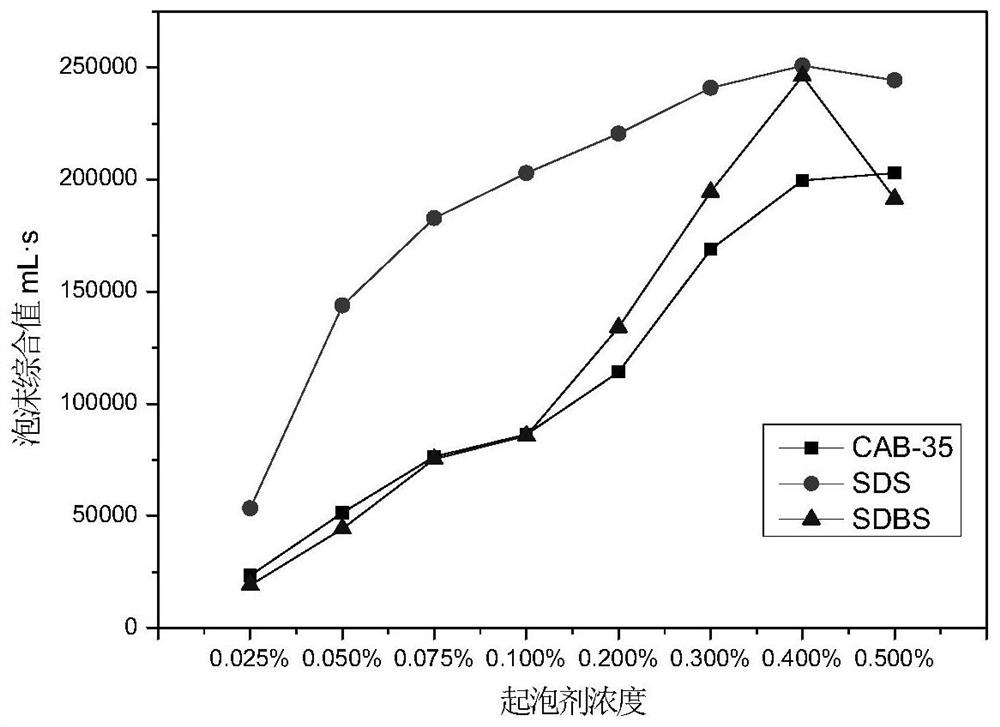

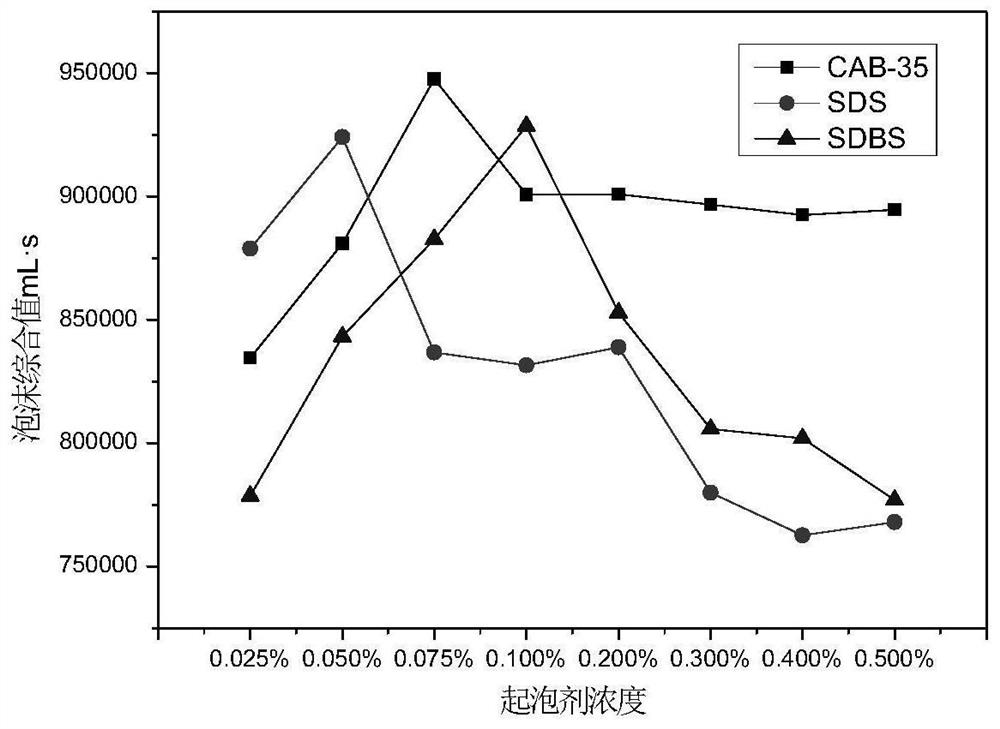

[0069] Embodiment 3, determination of foaming agent foaming ability and foam stabilizing ability

[0070] The foaming and foam stabilizing properties of the foaming agent were judged by recording the half-life and foaming volume of the water-based foam. Under the conditions of 25°C and 10000mg / L NaCl salinity, the volume, half-life and foam comprehensive value of water-based foam are shown in Table 3, figure 2 shown. It can be seen that the liquid separation half-life of the water-based foam of the three foaming agents increases as the concentration of the foaming agent first increases, and when the critical concentration is reached, the growth slows down or decreases slightly. Among them, the critical concentration of CAB-35 is 0.4 wt%, the critical concentration of SDS is 0.3wt%, and the critical concentration of SDBS is 0.4wt%. Depend on figure 2 It can be seen that for water-based foams, the foam integration value of SDS keeps the highest as the concentration increase...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com