Hydro-pneumatic suspension damping system of underground multifunctional service vehicle

A technology of oil and gas suspension and shock absorption system, which is applied to shock absorbers, gas-liquid shock absorbers, springs/shock absorbers, etc. problem, to achieve the effect of stabilizing the flow and ensuring the shock absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

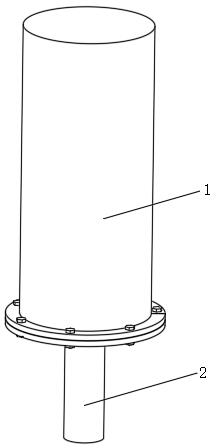

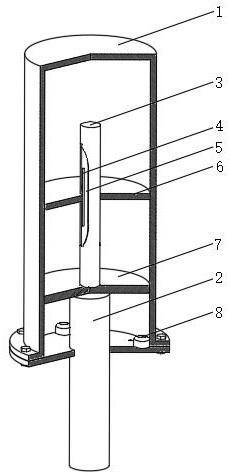

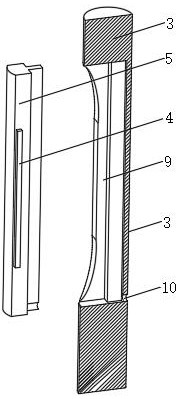

[0034] Example 1: Please refer to Figure 1-5 , this embodiment discloses an oil-gas suspension damping system for an underground multifunctional service vehicle, which includes a connecting rod 2, a piston 7, and a cylinder 1 with an open lower end, the outer peripheral side of the piston 7 is in sliding and sealed connection with the inner wall of the cylinder 1, and the piston 7 The lower side is connected to the upper end of the connecting rod 2, and the inner wall of the cylinder 1 is fixed with a partition plate 6, which is located above the piston 7, and the partition plate 6 is provided with a vertical damping hole, and a sliding rod is provided on the damping hole for sliding sealing. 3. The lower end of the sliding rod 3 is connected to the upper side of the piston 7. When the piston 7 moves up and down, the piston 7 drives the sliding rod 3 to move up and down along the damping perforation. The upper and lower ends of the sinking groove are all closed, and the inner...

Embodiment 2

[0047] Embodiment two: if Figure 6-9 As shown, this embodiment discloses an oil-gas suspension damping system for an underground multifunctional service vehicle. There is an adjustment assembly, the adjustment assembly includes a first permanent magnet 11, a bracket 17 and a sleeve 14 sleeved on the slide rod 3, the inner wall of the sleeve 14 is threaded to the lower part of the outer peripheral side of the slide rod 3, and the lower end of the sleeve 14 is connected to the piston 7 The upper sides are connected by rotating parts. The rotating parts include but not limited to bearings or rotating pin rings. The outer peripheral side of the sleeve 14 is fixed with the first permanent magnet 11 through the bracket 17;

[0048] A drive mechanism 12 is installed on the top of the connecting rod 2, and a second permanent magnet 13 corresponding to the first permanent magnet 11 is installed on the drive mechanism 12.

[0049] Furthermore, the lower part of the sleeve 14 is provid...

Embodiment 3

[0055] Embodiment three: as Figure 6 with Figure 7 As shown, this embodiment discloses an oil-gas suspension damping system for an underground multifunctional service vehicle. hole, the upper side of the piston 7 is fixed with a guide rod 16, and the upper part of the guide rod 16 is slidably engaged with the clamping hole. The outer peripheral side is provided with a vertical concave groove along the vertical direction or there is a gap between the guide rod 16 and the clamping hole to realize the flow of oil inside and outside the clamping hole. The sliding rod 3 enables the guide rod 16 to move up and down and cannot go around the vertical The shaft rotates and the position of the slide rod 3 relative to the piston 7 is adjusted by means of an adjustment assembly.

[0056] In another preferred solution, the horizontal cross section of the sliding rod 3 is a non-circular plane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com