A self-cleaning flue gas dust removal device and method

A dust removal device and self-cleaning technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of high operating costs, low dust removal efficiency, and high dust removal efficiency, so as to avoid the loss of flue gas waste heat, reduce Energy consumption and the effect of improving dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

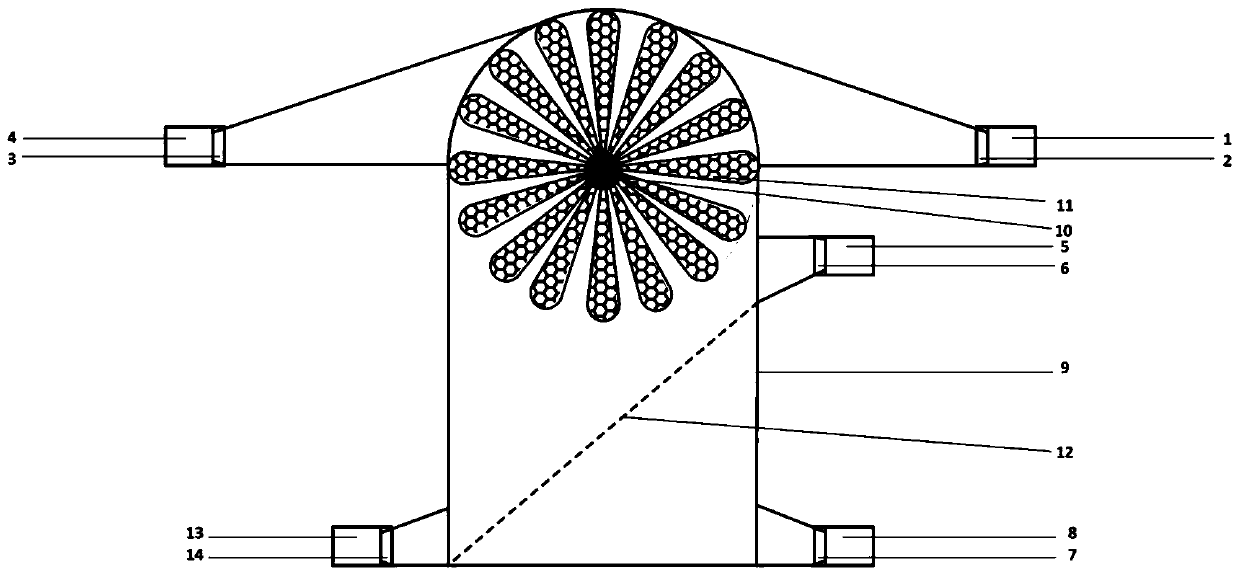

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0030] see figure 1 , the present invention includes a shell 9 with a semicircular structure at the upper end and a central shaft 10 arranged at the bottom center of the semicircular structure in the shell, and a dust removal impeller 11 made of porous ceramic heat insulating material with solid particle adsorption function is installed through the central shaft 10 In the casing 9, the tip of the blade of the dust removal impeller 11 is in close contact with the inner wall of the semicircular structure at the upper end of the casing 9;

[0031] The two sides of the semicircular structure at the upper end of the housing 9 are respectively equipped with a flue gas inlet pipe 4 and a flue gas outlet pipe 1 with a flue gas inlet valve 3 and a flue gas outlet valve 2;

[0032] The side of the flue gas outlet pipe 1 of the shell 9 is located at the lower end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com