Grinding device

A technology of grinding and grinding fluid, which is applied in the direction of grinding/polishing equipment, metal processing equipment, manufacturing tools, etc., and can solve the problem that the grinding fluid is difficult to reach the grinding tool, cannot supply the grinding fluid, scatter and adhere, etc. problems, to achieve the effect of efficient supply and restraint of usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

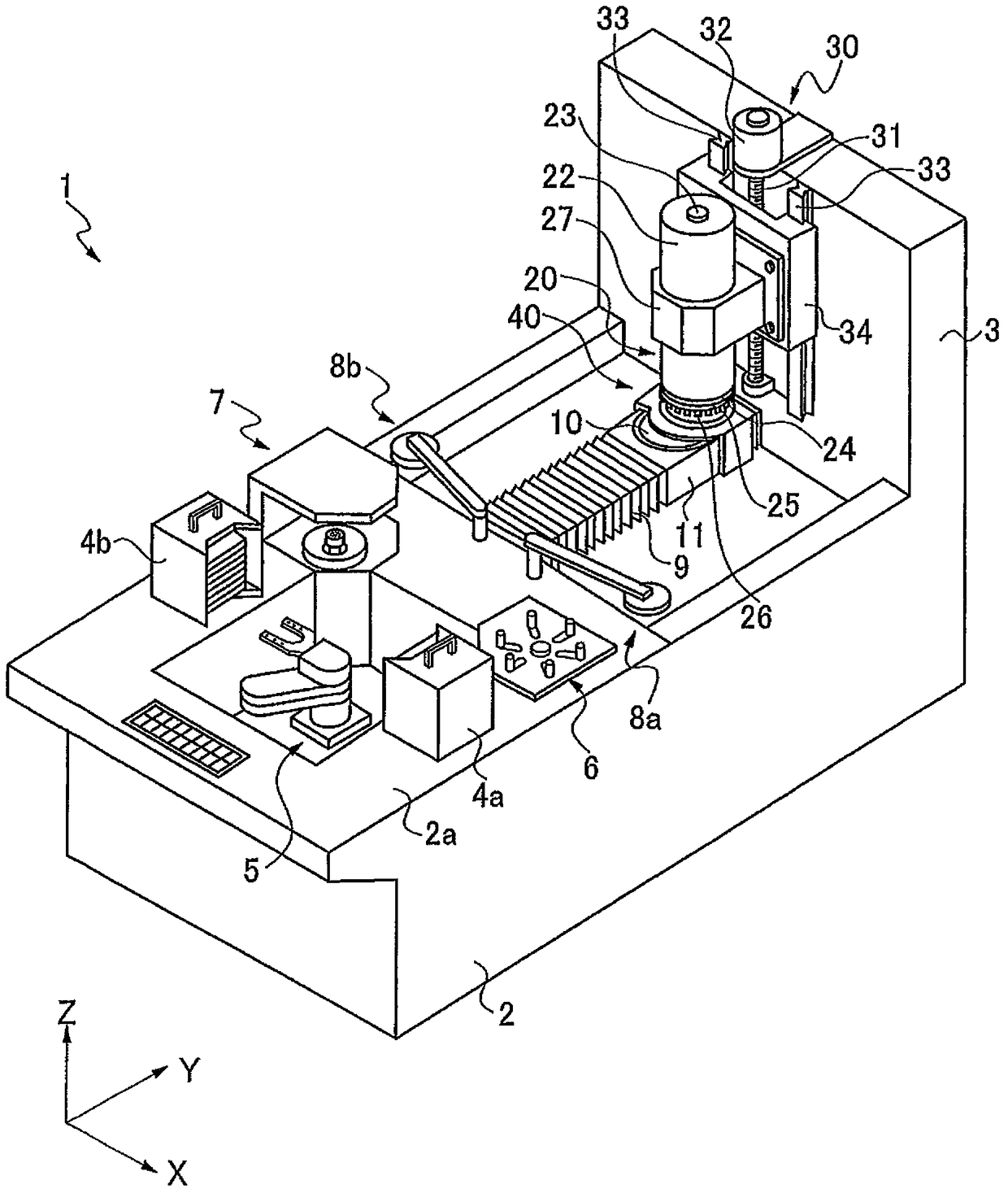

[0021] figure 1 The shown grinding device 1 is an example of a grinding device for grinding a workpiece, and has a device base 2 extending in the Y-axis direction. On the upper surface 2a of the apparatus base 2, a box 4a for storing a workpiece before grinding and a box 4b for storing a workpiece after grinding are arranged. Between the cassette 4a and the cassette 4b, the conveyance member 5 which carries out the to-be-processed object before grinding from the cassette 4a, and conveys the to-be-processed object after grinding into the cassette 4b is arrange|positioned. In the movable area of the conveyance member 5, a temporary placement member 6 for temporarily placing a workpiece and a cleaning member 7 for cleaning the workpiece after grinding are disposed.

[0022] A rotatable holding table 10 holding a workpiece is arranged on the device base 2 . The surrounding of the holding table 10 is covered by the holding table cover 11 , and the holding table 10 can reciproca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com