Piston for internal combustion engine

An internal combustion engine and piston technology, which is applied in the field of pistons used in internal combustion engines, can solve problems such as loss of function, and achieve the effects of prolonging service life and reducing loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

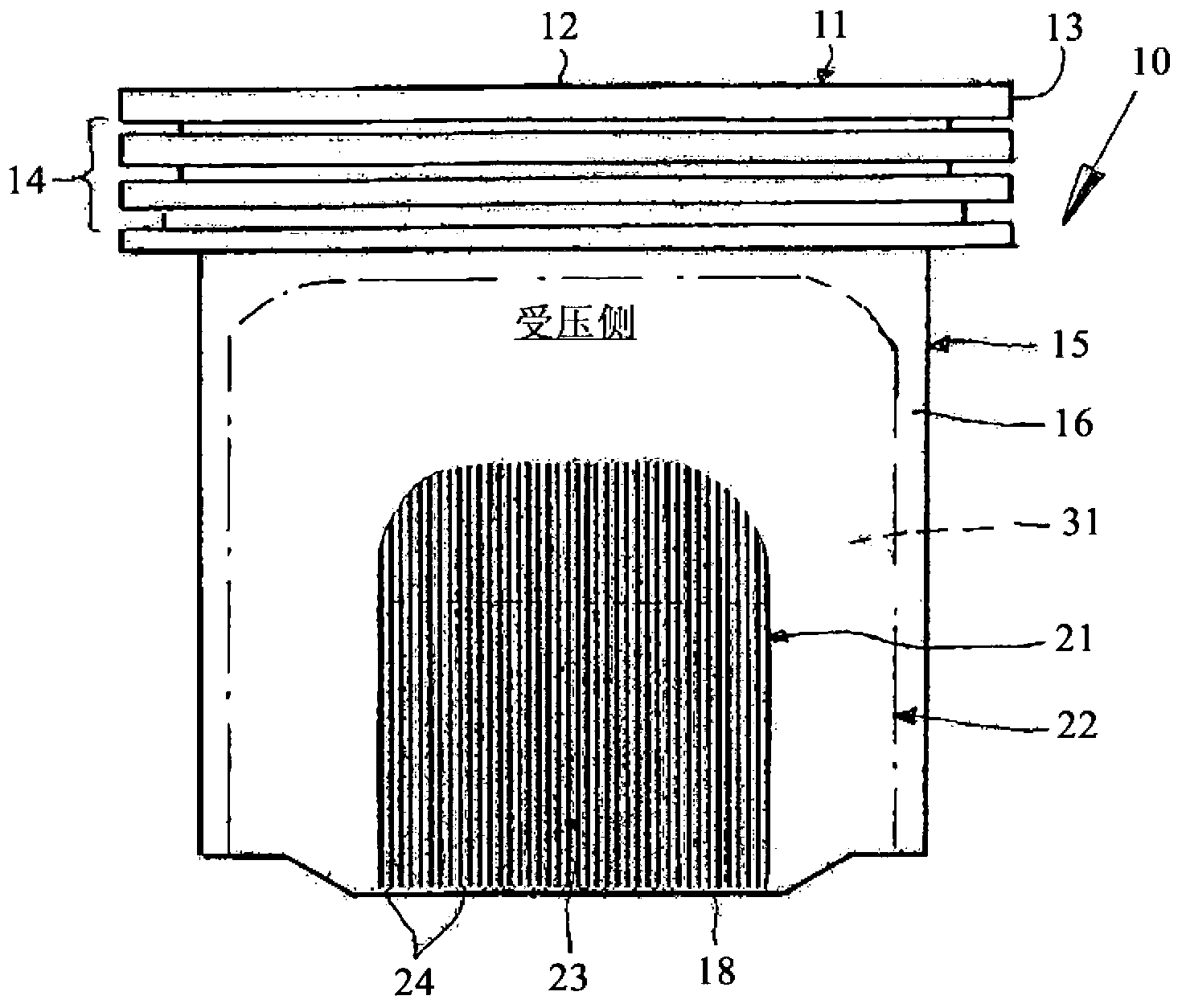

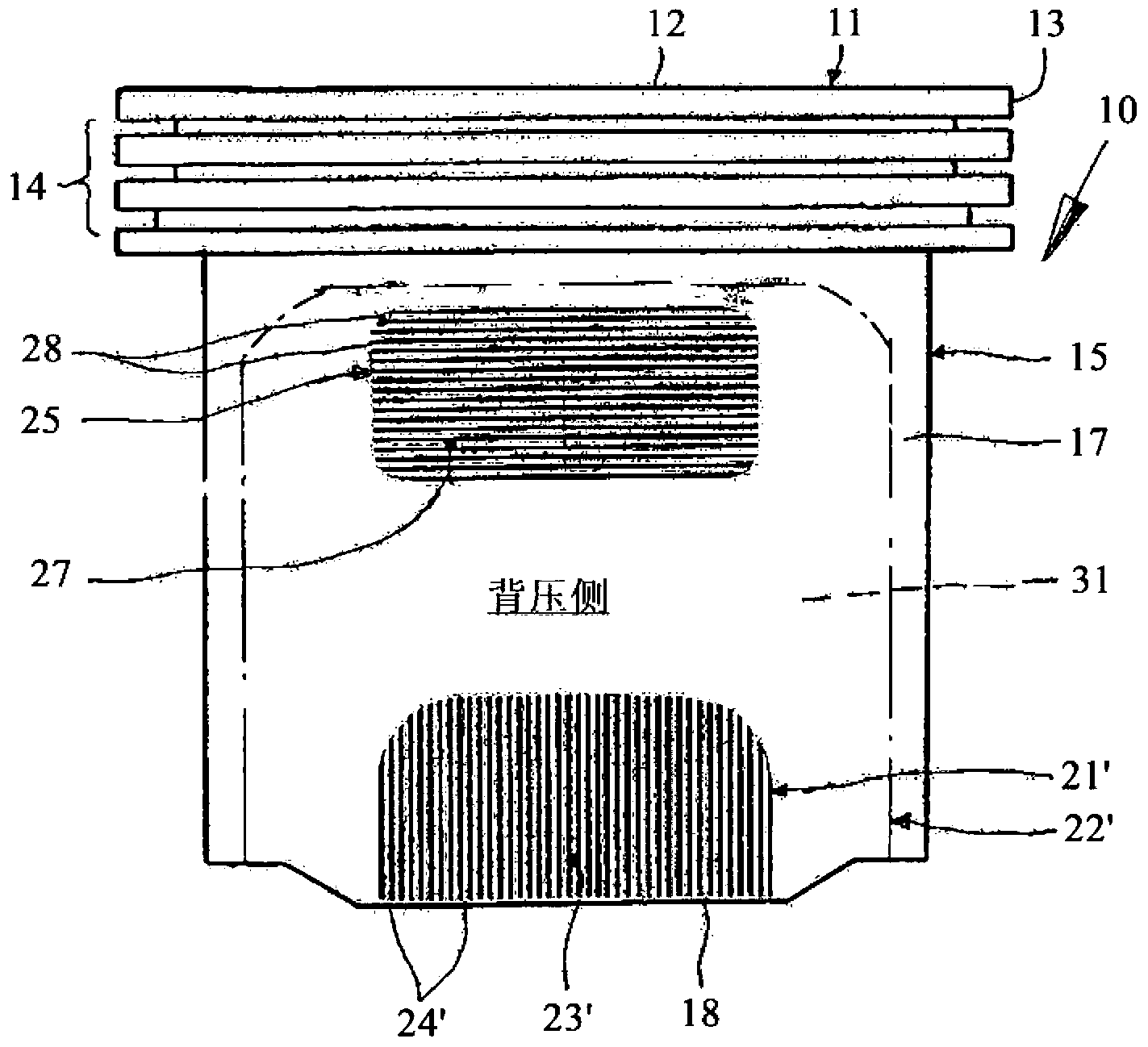

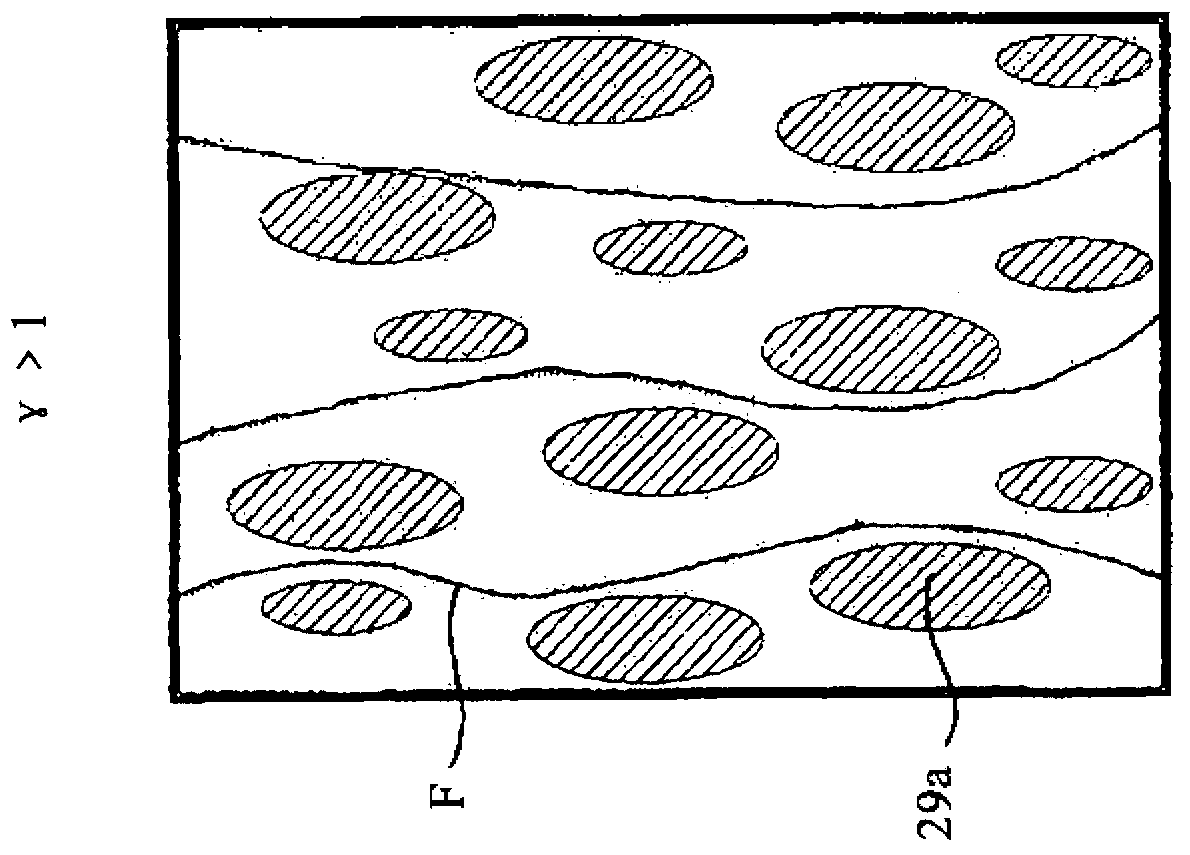

[0019] figure 1 and 2 An embodiment of a piston 10 according to the invention is shown. The piston 10 can be a one-piece or multi-part piston, for example a combined piston or a hinged piston. Piston 10 can be made of steel and / or light metal material. figure 1 and 2 A one-piece piston 10 is shown as an example. The piston 10 has a piston head 11 with a piston crown 12 ; a surrounding land 13 and an annular portion 14 for receiving piston rings (not shown). The piston 10 also has a piston skirt 15 with friction surfaces 16 , 17 . The piston skirt 15 is delimited by a lower skirt 18 . The friction surface 16 corresponds to the pressure side DS of the piston 10 (compare figure 1 ), while the friction surface 17 corresponds to the back pressure side GDS of the piston 10 (contrast figure 2 ). Other known structures of the piston skirt, such as hubs and hub bores, are not shown for clarity of illustration. The properties and load distribution of the pressure side and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com