Reinforced cooling type air cylinder head

A cylinder head, cooling type technology, applied in the direction of engine components, machines/engines, engine cooling, etc., can solve the problems of short spark plug cooling parts, short spark plug life, large matching tolerance between valve and cylinder head, etc., to improve the leakage pipe Structure, prolong service life, good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

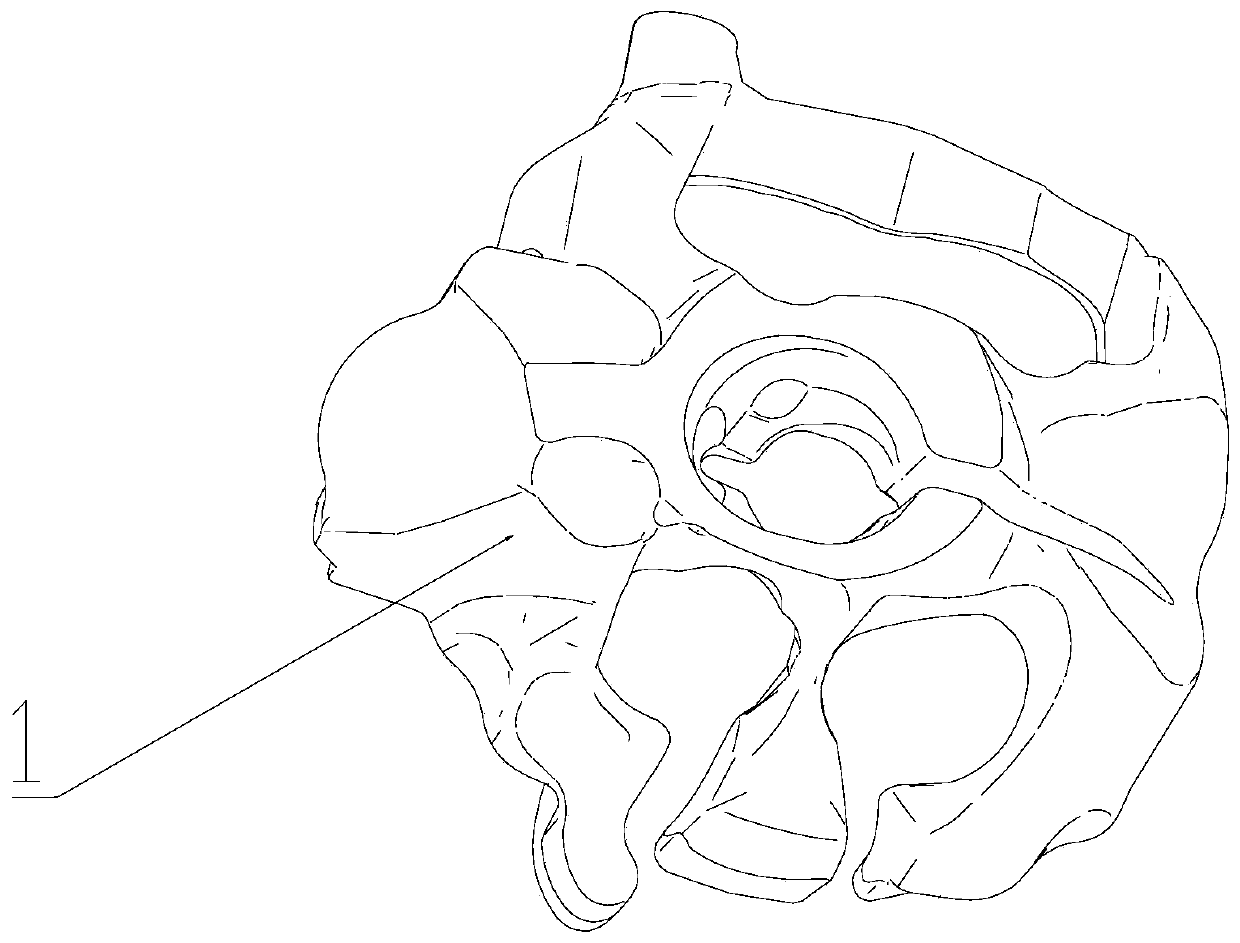

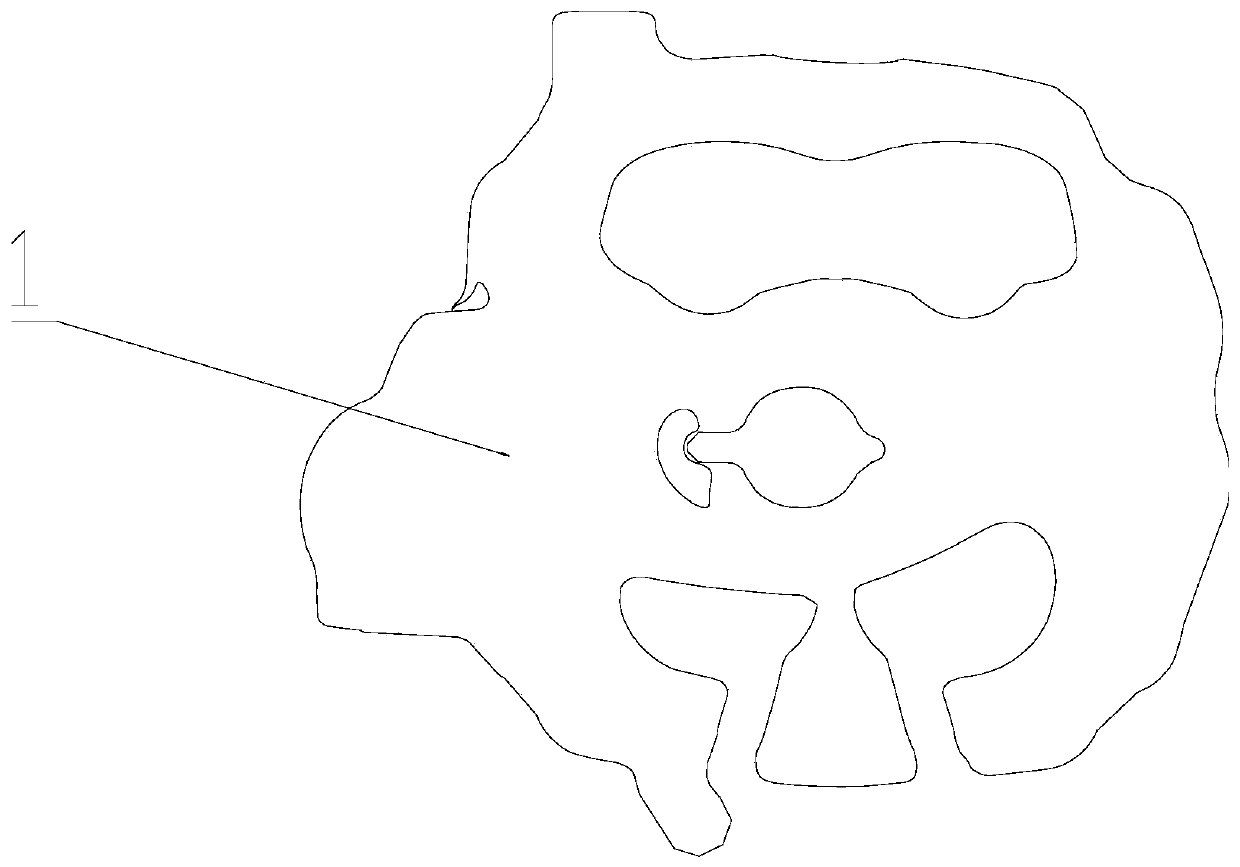

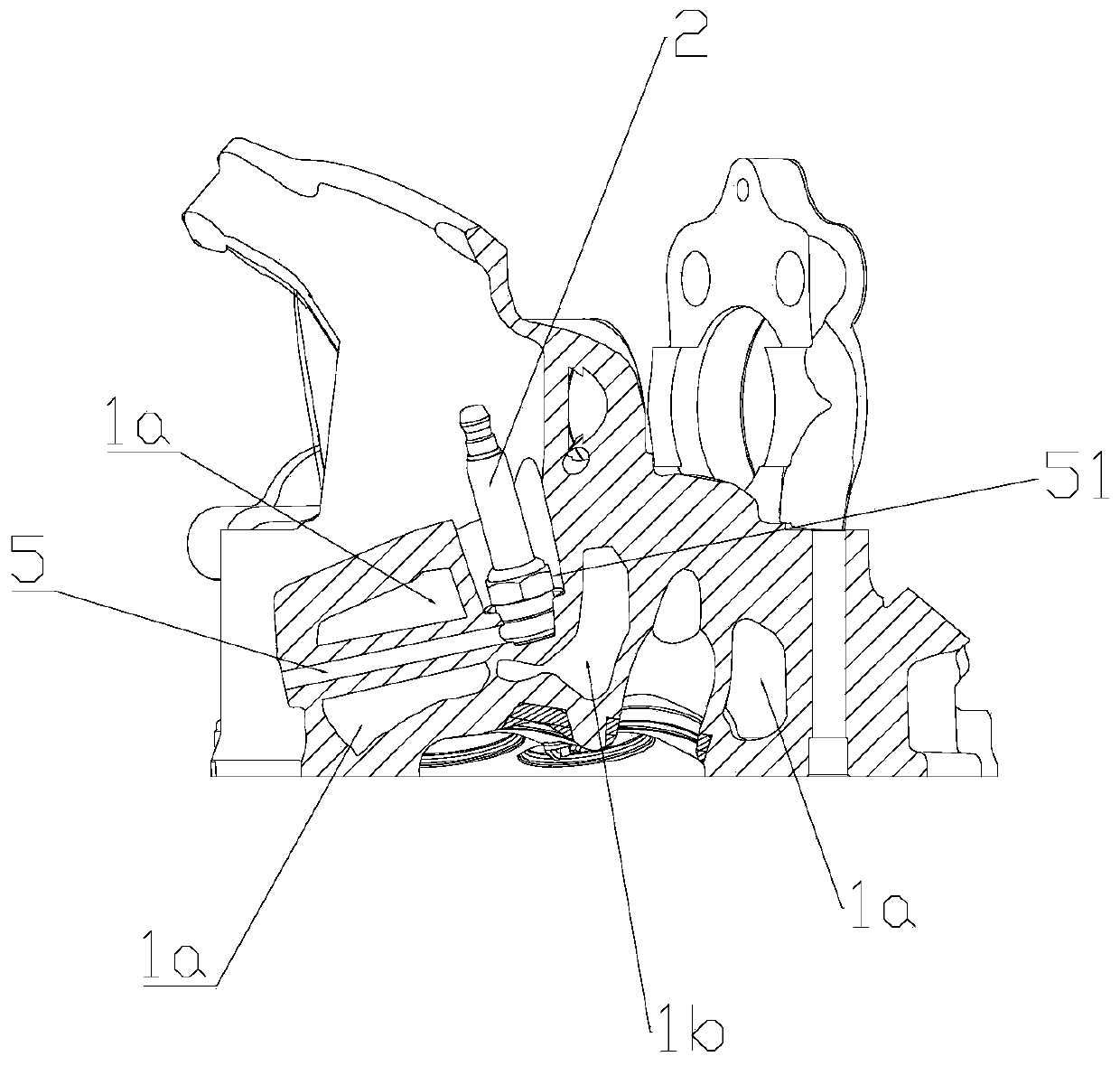

[0027] figure 1 It is a schematic diagram of the structure of the present invention, figure 2 for figure 1 top view of image 3 for figure 1 sectional view of Figure 4 for figure 1 sectional view of Figure 5 for figure 1 sectional view of Figure 6 for figure 1 bottom view of Figure 7 for Figure 6 Middle A-A section view, Figure 8 It is a schematic diagram of the internal cooling water flow of the present invention, Figure 9 It is a structural schematic diagram of the prior art, Figure 10 for Figure 9 sectional view of Figure 11 for Figure 9 sectional view of Figure 12 It is a schematic diagram of the complete engine of the present invention, as shown in the figure, the arrow in the figure indicates the cooling water flow direction in the cylinder head body 1, Figure 9 and Figure 10 and Figure 111' among them represents the water jacket of the prior art, 1a' represents the cooling water cavity in the water jacket of the prior art, 2' repre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com