Disc drill bit with steerable wheel discs

A technology of roulette and drill bit, which is applied in the direction of drill bit, drilling equipment, earthwork drilling and mining, etc. It can solve the problems of short life of cutting teeth, aggravated wear of roulette ring gear, breakage of roulette ring gear, etc., so as to reduce wear and improve Rock-breaking efficiency and the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

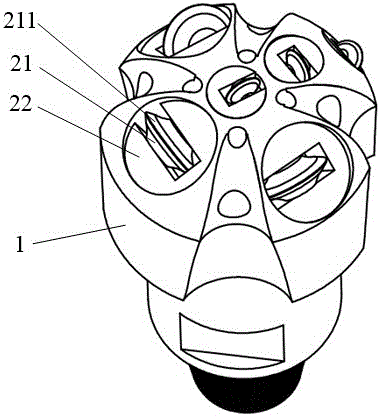

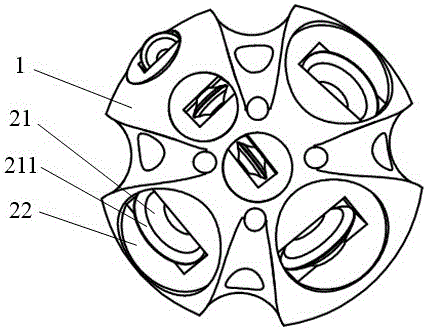

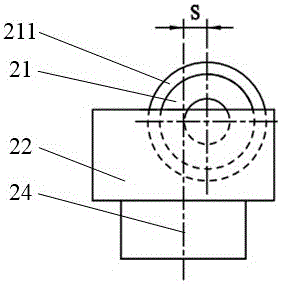

[0032] refer to Figure 1-6 As shown, a disc-type drill bit with a turnable roulette includes a drill body 1 and a roulette 21. The roulette 21 is provided with a ring gear 211. The roulette 21 can rotate relative to the drill body 1. The drill body 1 is provided with at least A steering wheel, the steering wheel is made up of a wheel 21 and a steering seat 22, the steering seat 22 is mounted on the drill body 1 through a rotational connection, the steering seat 22 can rotate relative to the drill body 1, and the wheel 21 is installed on the steering wheel through a rotational connection On the seat 22, the wheel disc 21 can rotate relative to the steering seat 22. Alternatively, as shown in this embodiment, the drill body 1 is correspondingly provided with a hole for accommodating a steering seat 22 matching the steering wheel, and the steering seat 22 enters the hole and rotates on the drill body 1 . Steering seat 22 can have various forms, for example image 3 , 5 Be tha...

Embodiment 2

[0034] This embodiment is basically the same as Embodiment 1, the difference being that: the wheel disc 21 and the steering seat 22 are connected by a shaft, and the shaft and the wheel disc 21 are connected by rotation. Or, the shaft and the wheel 21 are fixedly connected or the shaft and the wheel are integrated, and the shaft and the steering seat 22 are connected in rotation. Or, there is a rotational connection between the shaft and the wheel 21 , and a rotational connection between the shaft and the steering seat 22 .

Embodiment 3

[0036] This embodiment is basically the same as Embodiment 1, the difference being that a locking structure 4 is provided between the steering seat 22 and the drill body 1 to limit the movement of the steering wheel in the direction of the rotation axis 24 of the steering seat 22 . A circlip structure can be set between the steering seat 22 and the drill body 1 to prevent the steering wheel from moving in the direction of the rotation axis 24 of the steering seat 22 or falling off along the axis; Structure, the steering seat 22 is limited in the steering seat hole of the drill body 1 by the nut to prevent the steering wheel from moving or falling off in the direction of the rotation axis 24. As a further option, ball locking is adopted between the steering seat 22 and the drill bit body 1 (such as Figure 8 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com