High-efficiency rock-breaking combination tool with punching-and-rotating scraping-and-cutting stepping function

A combined tool and stepped technology, applied in the direction of drill pipe, casing, drill pipe, etc., can solve the problems of slow drilling speed, low drill bit life, incompatibility, etc., and reduce drilling tool vibration and tripping. Time and cost, the effect of speeding up drilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing:

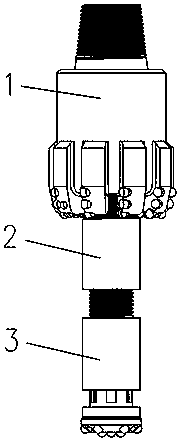

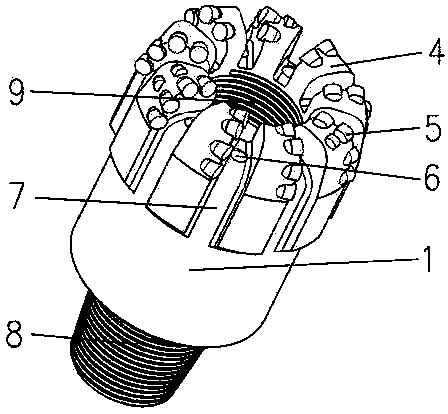

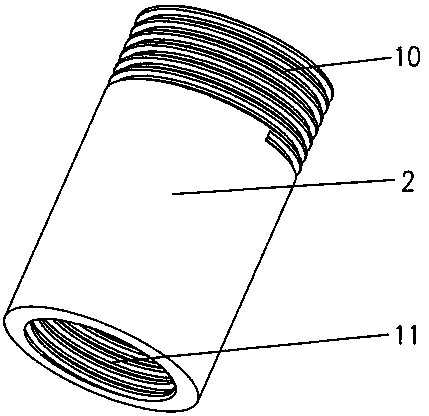

[0015] like figure 1 , figure 2 , image 3 , Figure 4 As shown, the present invention is a high-efficiency rock-breaking combined tool of punching-scraping step action, which is composed of a front impact drill bit 3, a short joint 2 and a PDC drill bit 1, and the front impact drill bit 3 and the short joint 2 pass through the pin 12 is connected with the box 11, and the front impact drill 3 provides continuous hydraulic power through the drilling fluid to generate impact load; the pup joint 2 and the PDC bit 1 are connected through the pin 10 and the box 9; the front impact drill 3 is placed on the There are multiple impact teeth 15, multiple water spray holes 13 and chip removal grooves 14; the PDC teeth 5 are distributed diagonally on the PDC bit blades 4; chip removal is designed between every two adjacent PDC blades 4 The groove 7 and the chip removal groove 7 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com