Compound tooth-shaped conical broken grinding head with point press teeth and long strip sieve pores

A long sieve and cone crushing technology, applied in grain processing, etc., can solve the problems of increased grinding material loss, poor discharge of qualified materials, and unusability, and achieve the effect of avoiding repeated crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

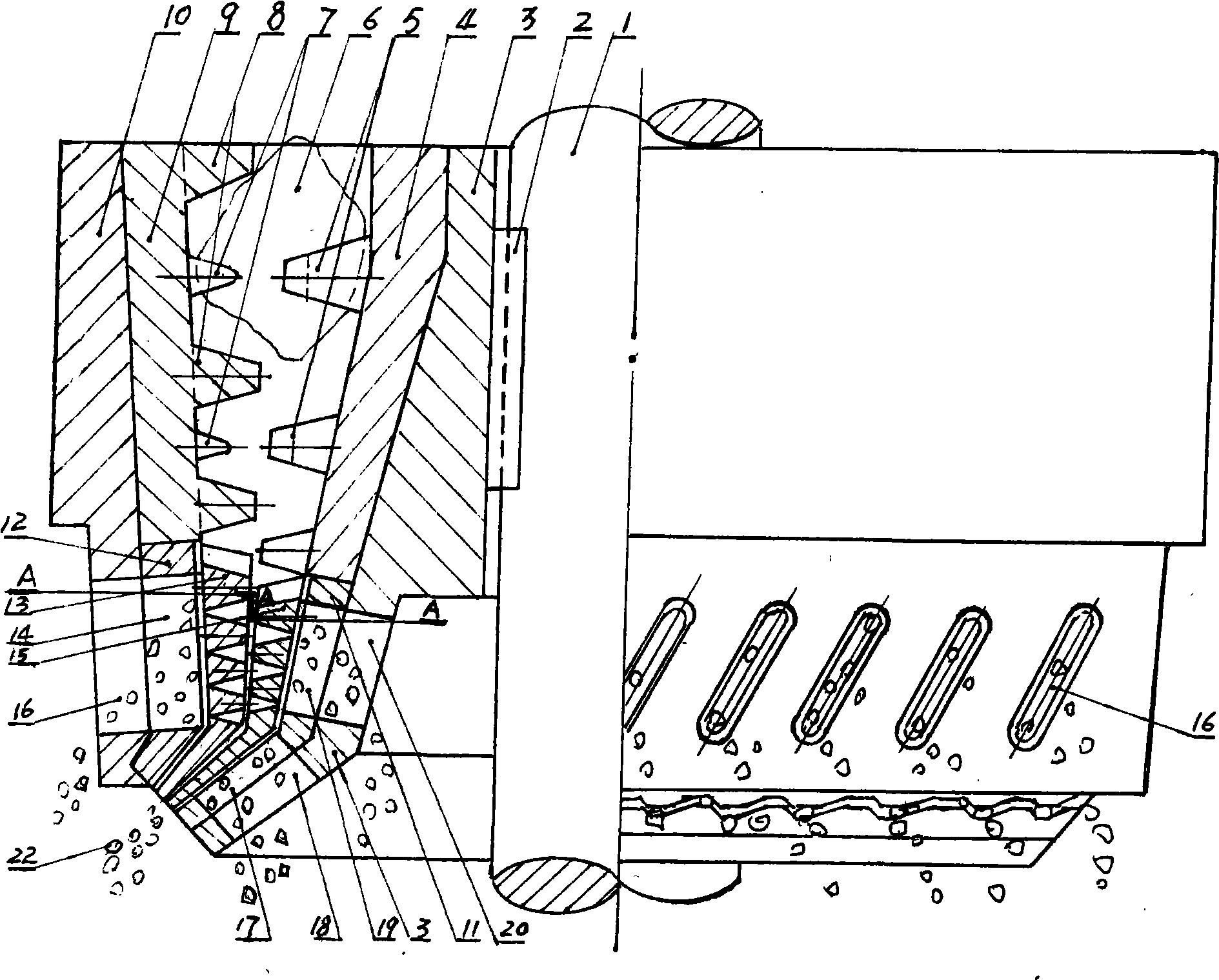

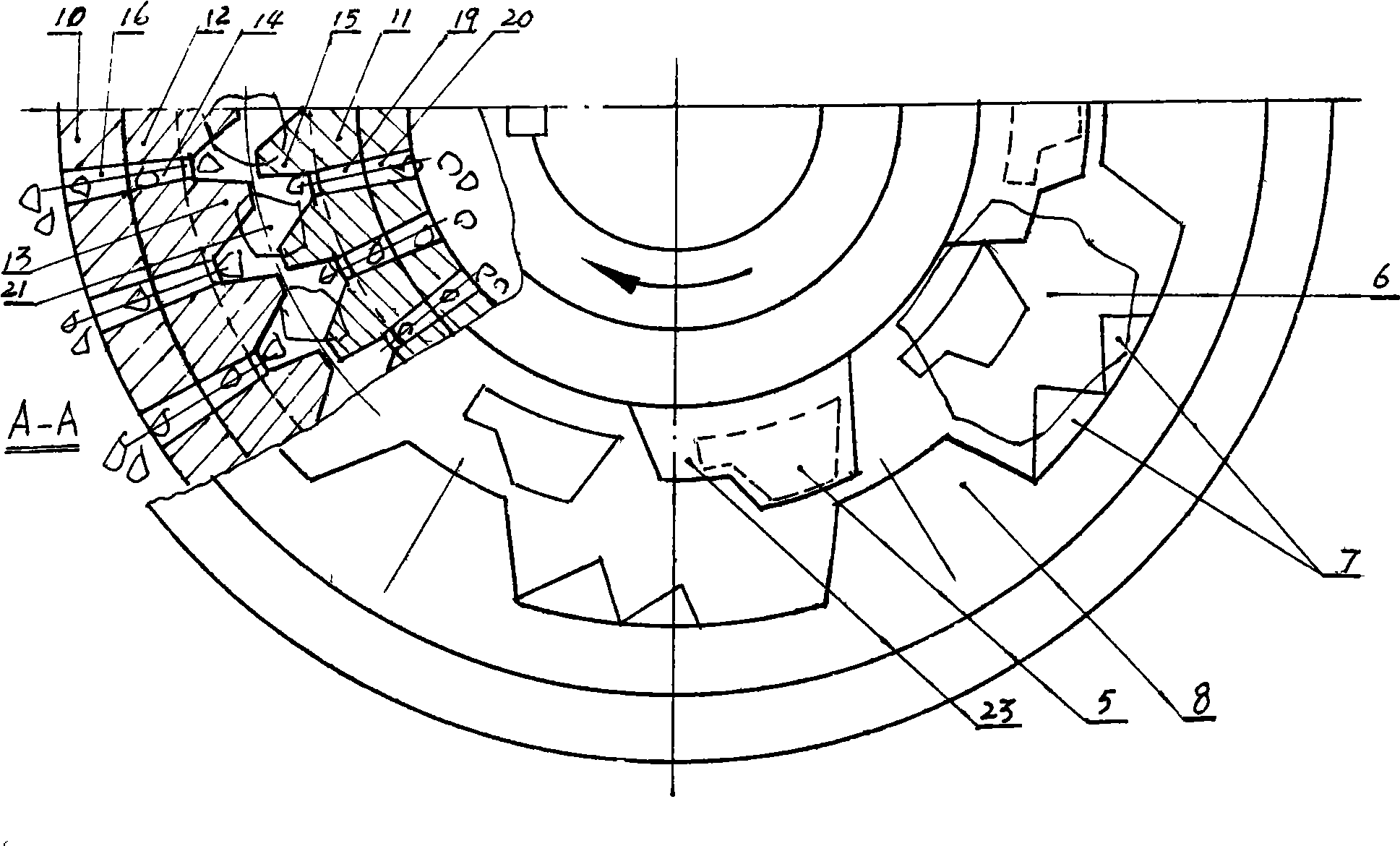

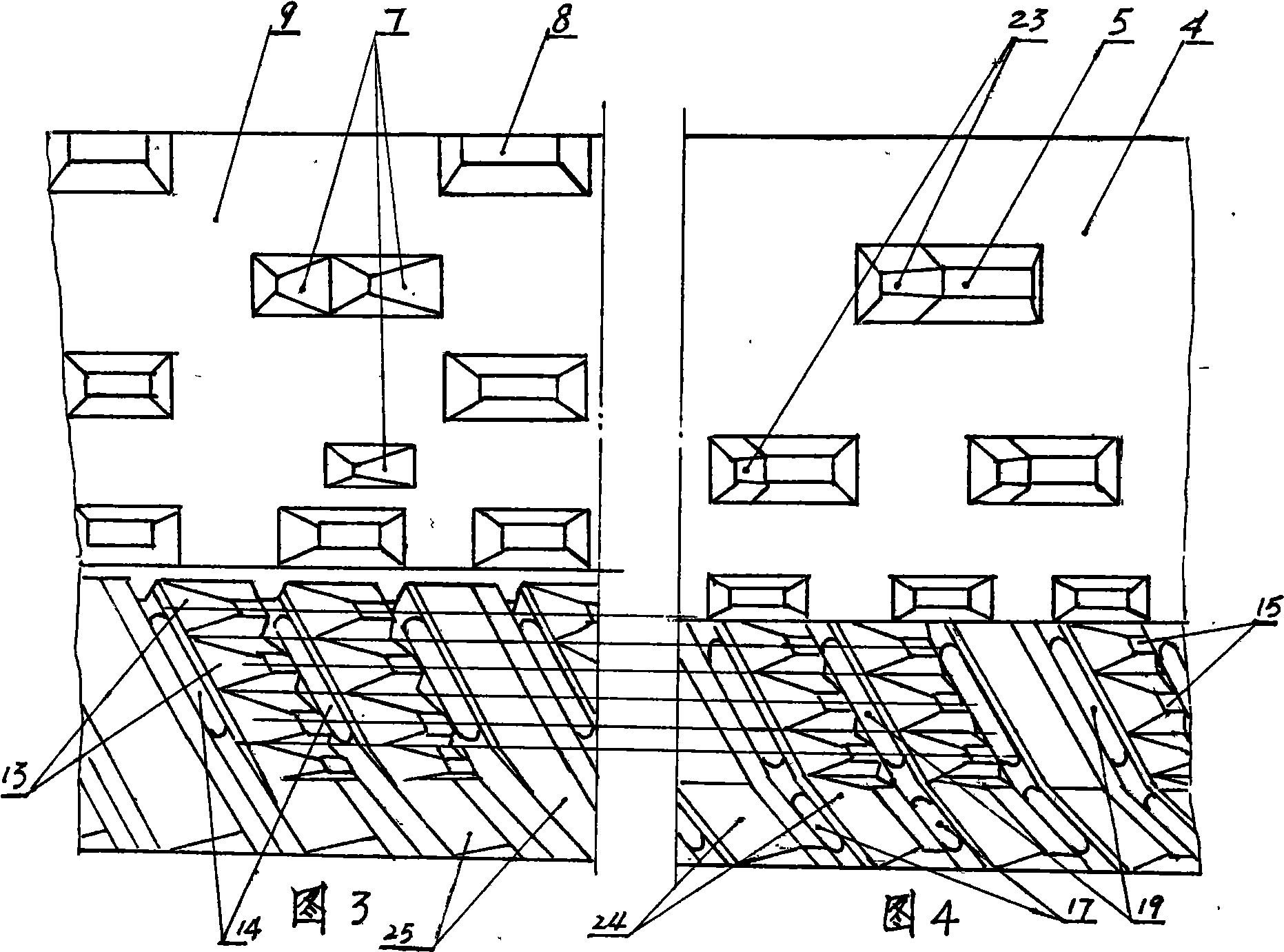

[0013] in Figure 1 to Figure 4 Among them, a split upper inner cone liner (4) is installed on a main shaft (1) and an inner cone sleeve (3) by a key (2). There are multiple rows of impact teeth (5) in the transverse direction, and the impact surface of the impact teeth is provided with a triangular point pressing boss (23). The upper outer cone liner (9) installed on the outer cone sleeve (10) has a bit of pressing teeth (7). The lower inner cone lining plate (11) and the lower outer cone lining plate (12) are respectively provided with bar-shaped tooth transverse teeth (15) and (13) with an axial inclination angle to form an inverted triangular crushing cavity. When a large piece of material enters the crushing cavity, it is split and broken by the point pressing boss (7) on the impact tooth (5) and the point pressing tooth (7) on the upper outer cone (9). It is stuck on two rows of large trapezoidal teeth (8), and the top plan view is a notched space, and then the impact teeth (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com