Fine sand screening device

A kind of sand screening and fine technology, applied in the direction of screening, solid separation, grid, etc., can solve the problems of prolonged operation time, screening effect to be improved, inability to efficiently separate fine sand and waste residue, etc., to improve screening effect, improve The effect of waste residue removal rate and improving screening rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

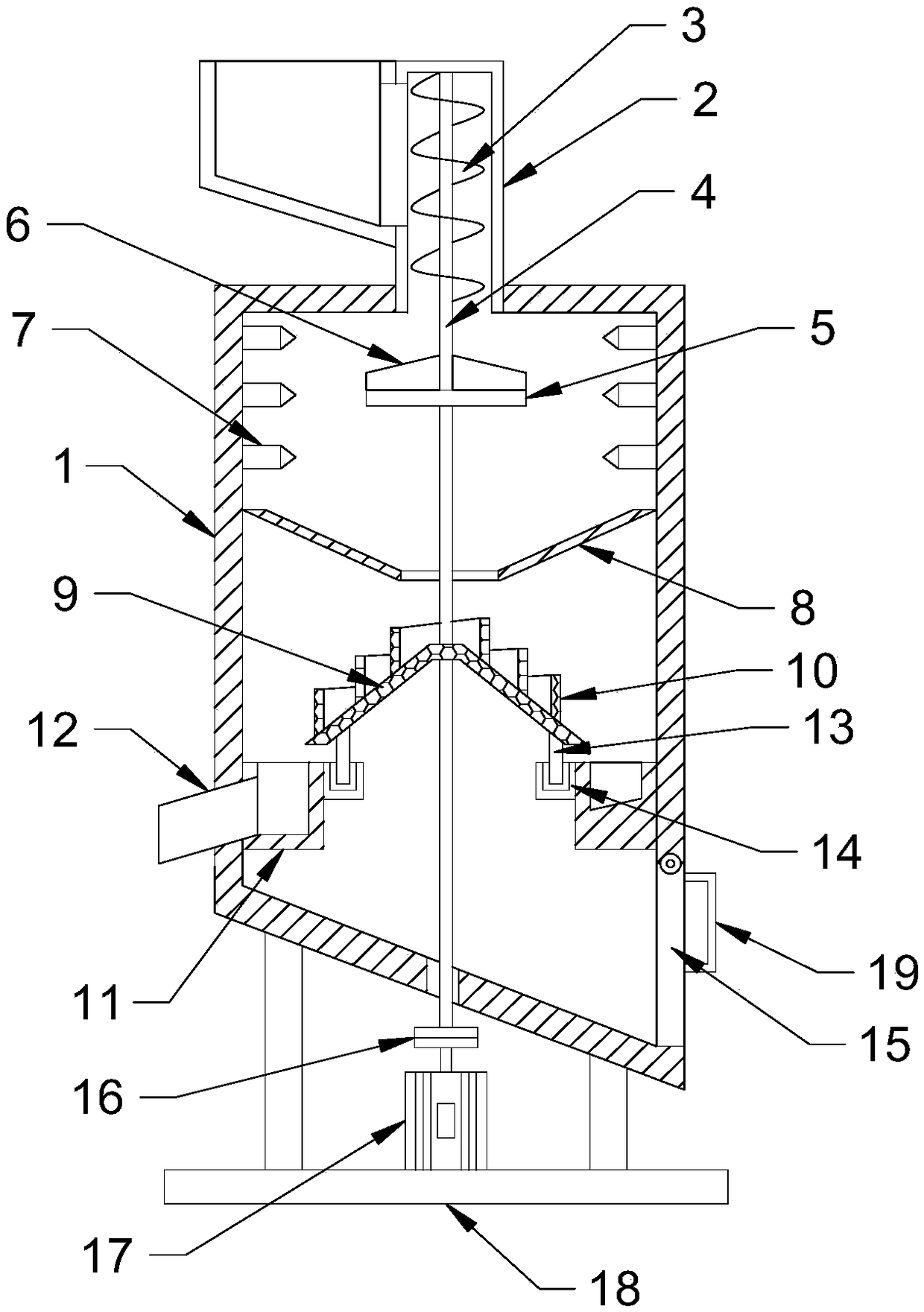

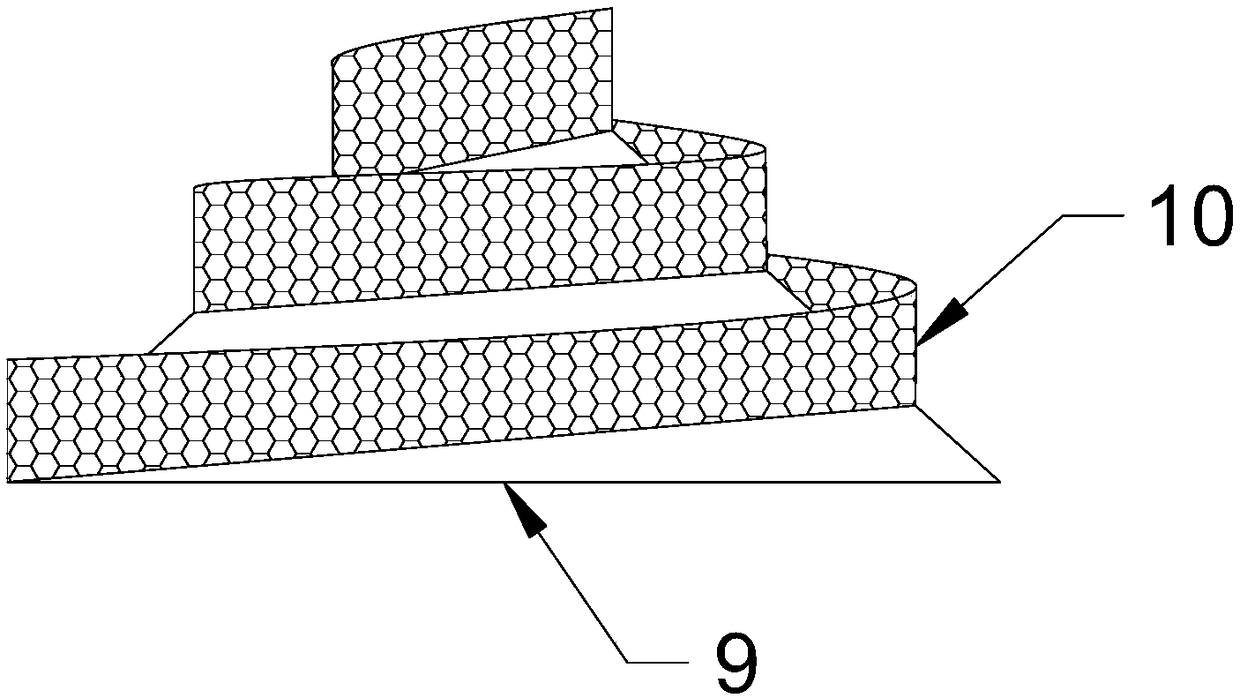

[0024] see Figure 1~5 , in an embodiment of the present invention, a fine sand screening device includes a box body 1, an impact mechanism and a sand screening mechanism; the inner end of the box body 1 is connected with a feed pipe 2, and a feed screw is provided in the feed pipe 2. The blade 3 and the feeding spiral blade 3 are fixedly connected with the central shaft 4, the central shaft 4 extends to the bottom of the box body 1 and is connected to the output shaft of the driving motor 17 through the coupling 16, and the driving motor 17 is fixedly connected with the The base 18, the base 18 is fixedly connected with the box body 1, and the drive motor 17 drives the feeding screw blade 3 to rotate through the central shaft 4, so as to avoid the blockage of the feeding pipe 2 and ensure the controllable feeding speed;

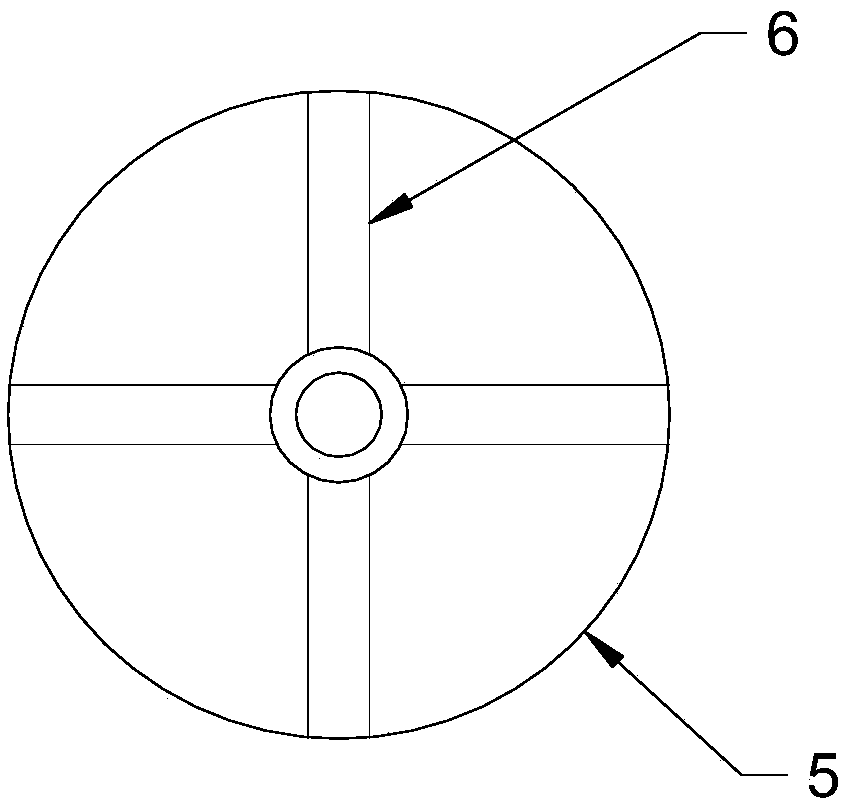

[0025] The box body 1 is provided with an impact mechanism, and the impact mechanism includes a scattering plate 5 and an impact tooth 7; the upper end surf...

Embodiment 2

[0029] see Image 6 , the difference between this embodiment and Embodiment 1 is: a crushing knife 20 is provided below the throwing disc 5, and the crushing knife is fixedly connected with the central shaft 4, and the central shaft 4 drives the crushing knife 20 to sand blocks after impact. Carry out further crushing to ensure that the sand material is fully dispersed for subsequent screening.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com