PDC drill bit with self-impact capability

A technology of impact capacity and drill bit, which is applied in the fields of tunnel engineering, geological drilling, oil and gas drilling engineering, and mining engineering. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

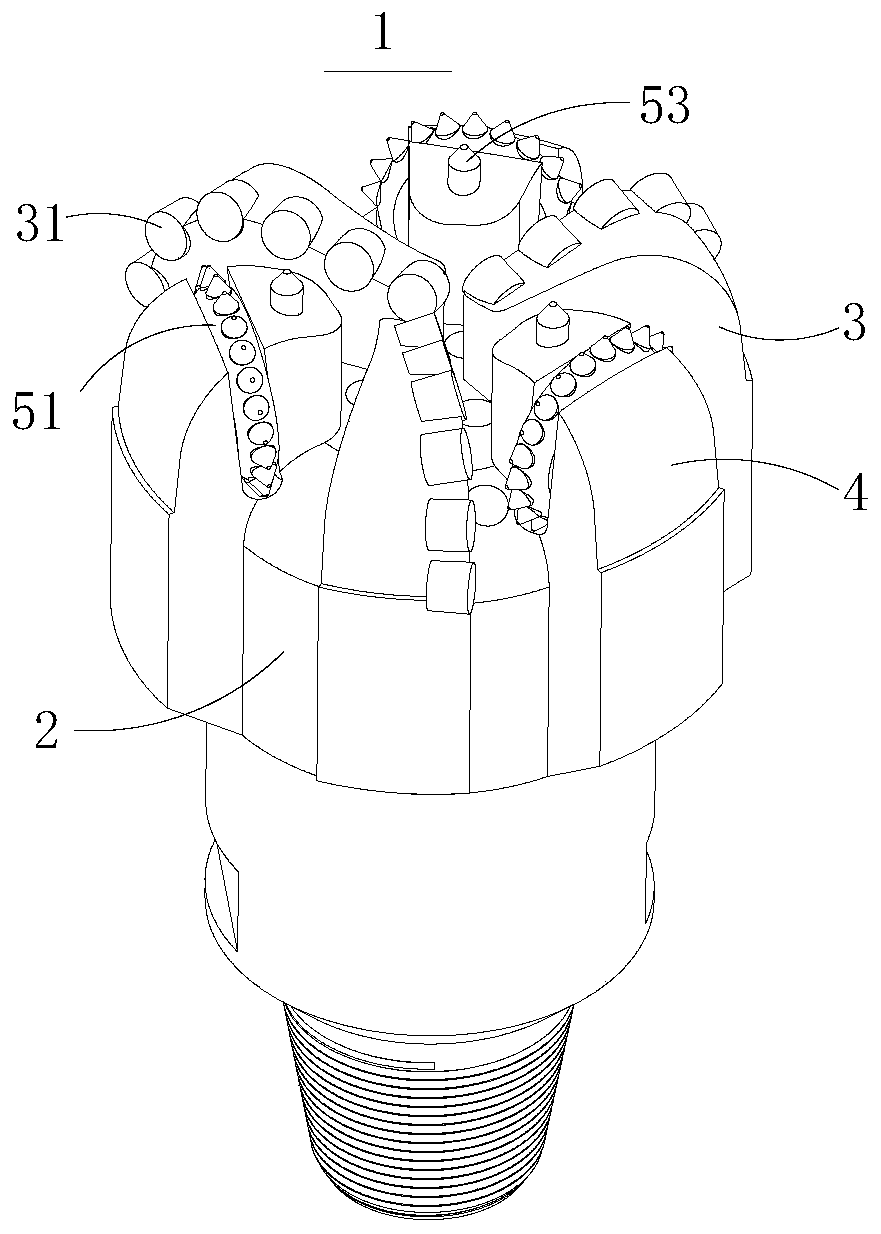

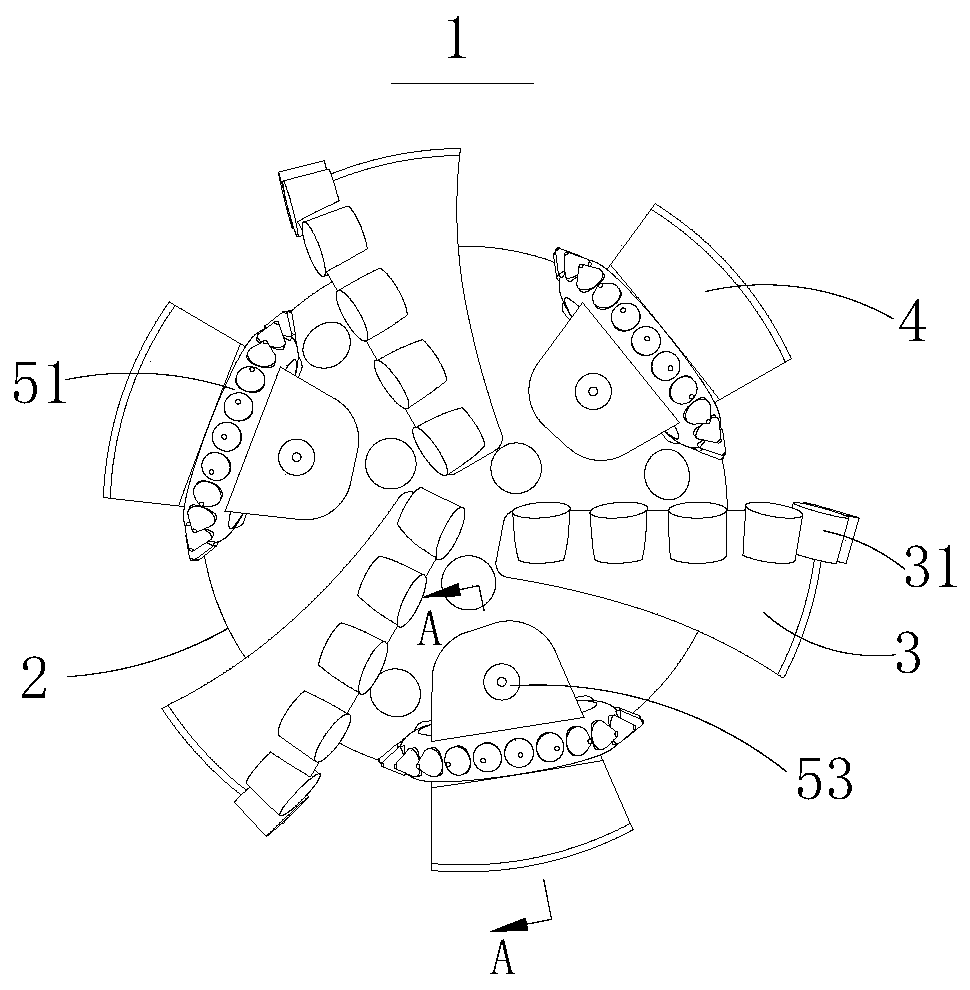

[0047] see Figure 1-Figure 10 , the embodiment of the present invention provides a PDC drill bit 1 with self-impacting capability.

[0048] see figure 1 , figure 2 , the PDC drill 1 includes a drill body 2, a blade 3, the blade 3 is fixedly connected with the drill body 2 or integrally formed, the blade 3 is provided with cutting teeth 31, the drill body 2 is provided with a support body 4, the support body 4 A self-impact unit 5 is arranged on it.

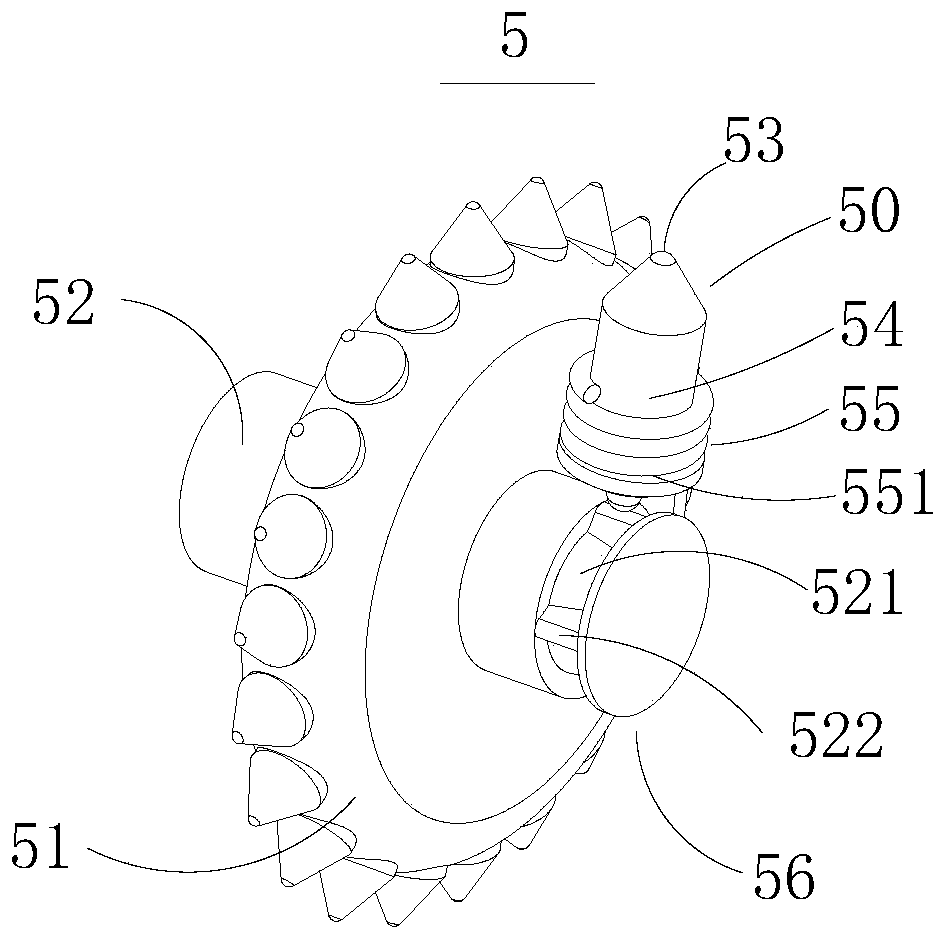

[0049] see image 3 , the self-impact unit 5 is composed of a rolling body 51, a transmission 56 and an impact device 50; the rolling body 52 can rotate around its own axis; the impact device 50 is composed of an impact body 54 and at least one impact tooth 53; the rotation of the rolling body 51 can pass The transmission 56 implements the striking of the striking tooth 53 in the striking direction. Apparently, the supporting body 4 can be independently arranged on the drill body 2, or can be fixedly connected with the bla...

no. 2 example

[0059] The embodiment of the present invention provides a PDC drill bit with self-impacting ability, the structure of this PDC drill bit 1 is basically the same as that of the PDC drill bit 1 in the first embodiment, the difference is: please refer to Figure 11 , in this embodiment, the transmission device 56 is a slider crank mechanism, which includes a transmission shaft 52, an intermediate connecting rod 60, the transmission shaft 52 is fixedly connected to the rolling body 51, and the intermediate connecting rod 60 is connected to the transmission shaft 52 and the impact body 54 respectively. Hinged, the impact body 54 forms a sliding connection with the support body 4, so that the rotation of the rolling body 51 can realize the impact of the impact teeth 53 towards the impact direction through the slider crank mechanism. The output of the slider crank mechanism is stable, and the impact on the transmission shaft 52 will not be reversed due to the contact of the impact too...

no. 3 example

[0061] The embodiment of the present invention provides a PDC drill bit with self-impacting ability, the structure of this PDC drill bit 1 is basically the same as that of the PDC drill bit 1 in the first embodiment, the difference is: please refer to Figure 12-Figure 15 , a cutting tooth 31 is provided on the support body 4 .

[0062] The cutting teeth 31 are arranged on the supporting body 4, which makes full use of the precious space on the drill bit, and can also significantly increase the tooth density of the drill bit, prolonging the service time of the drill bit. Especially for formations with strong abrasiveness, the higher the tooth density means the more diamond content on the drill bit, and the stronger the wear resistance. It is easy for researchers in the field to imagine that the cutting teeth 31 are arranged in front of the impact teeth 53 (see Figure 12 ), or rear (see Figure 13 ), or be set at the front and rear of the impact tooth 53 simultaneously. rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com