Impact rock breaking mechanism testing device

A test device and rock crushing technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as complex structure, inability to replace impact teeth, and axial pressure applied to rock samples, and achieve good test repeatability and automation High and safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

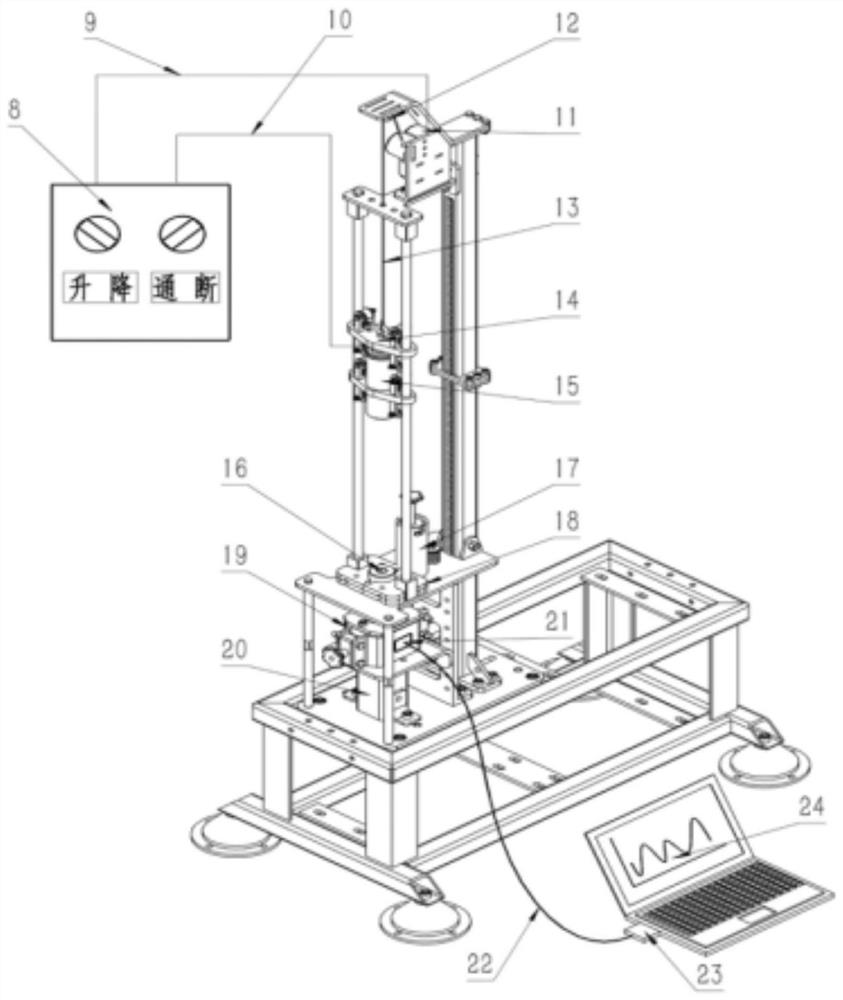

[0074] See figure 1 Showing the mechanism of rock crushing impact test apparatus according to the present invention, the pedestal, the hammer mechanism, the clamping mechanism crushed rock, the preload mechanism, the control section, the top and bottom mounting mechanism and the like. The crushed rock hammer mechanism located above the clamp assembly and the clamp assembly is on rock fragmentation, by adjusting the height of impact of the hammer mechanism and / or ram mass Rock Fragmentation by adjusting the size of the impact energy, comprising a ram assembly and a magnetic lifting assembly, said lifting assembly comprises a magnetic structure and the magnetic structure lifting pulley, the pulley structure includes a lifting column 2 and the vertical uprights 2 are connected with the two parallel guide rods (guide rods 4 left, right guide 5 bar), the scale 3 is attached to the front pillar 2. Preload mechanism includes a clamp assembly and the anti-rebound pressure fixing assembl...

Embodiment 2

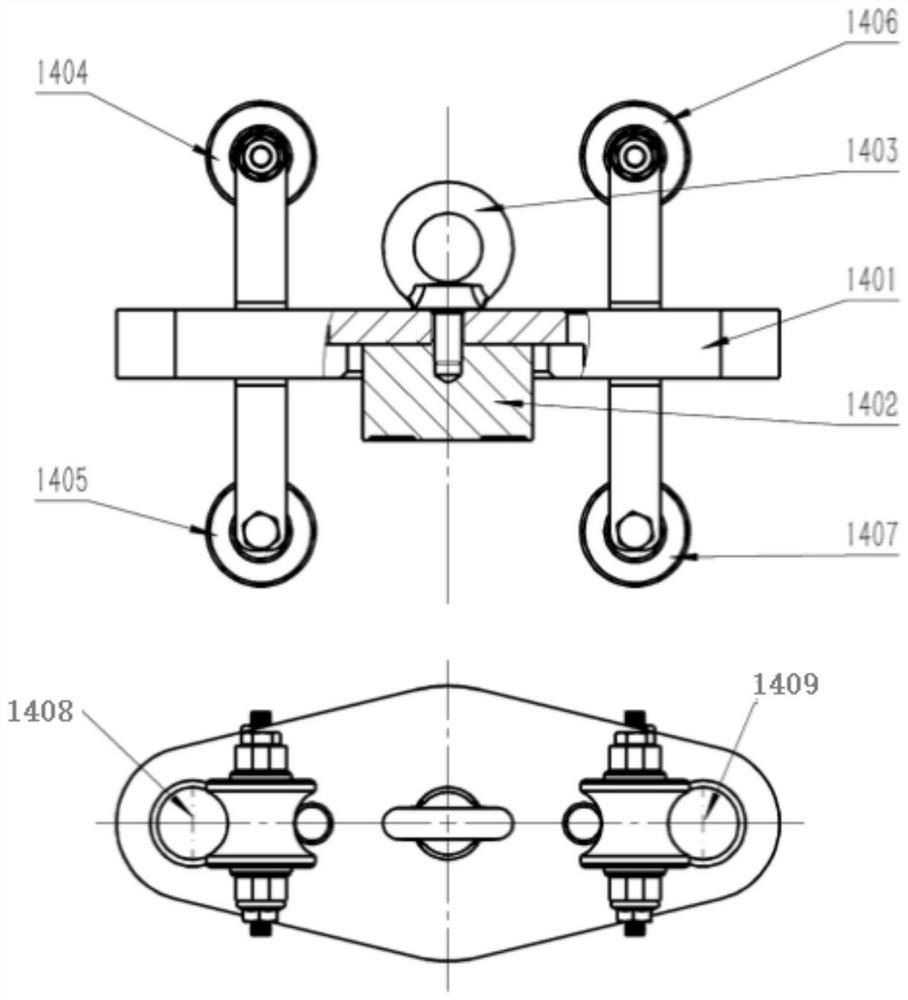

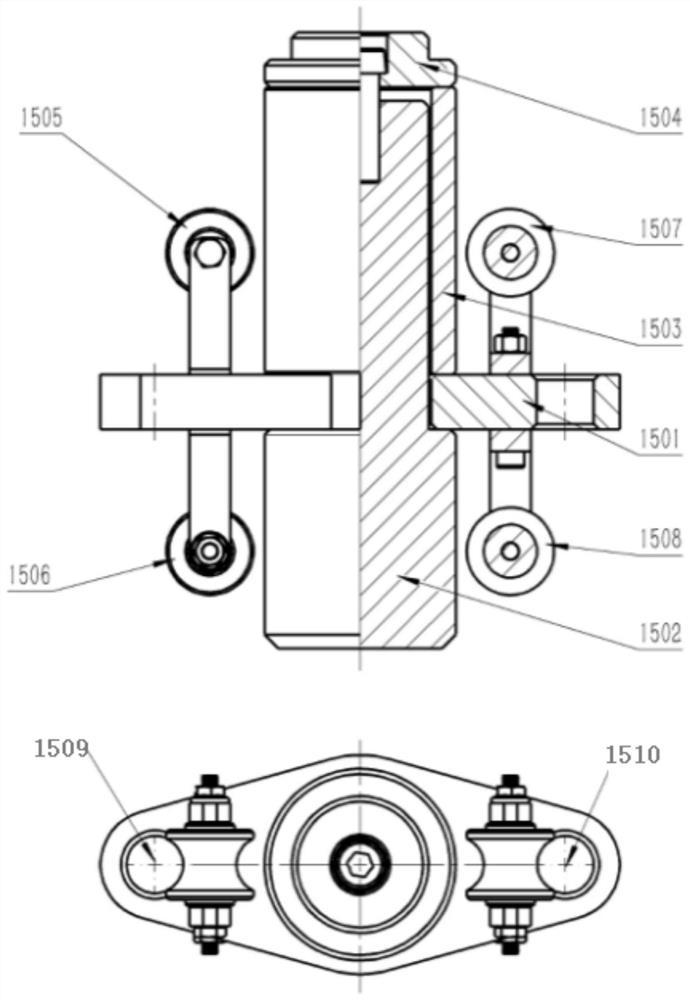

[0095] The present embodiment provides a mechanism crushed rock impact test apparatus, comprising a base 1, column 2, the hammer assembly, the lifting magnet assembly 14, the guide rod, the anvil member 20 rock samples, rock samples jig cube, crushed rock tool clamp mechanism the pressing mechanism, the hoisting machine 11, the scale 3, the wire rope 13, the control box, sensors, monitoring equipment and data transmission cable or the like, is mounted on the pillar 2, the upper end of the guide rods 4 and 5 of the right seat on the left guide rod 1 column 2 is connected to the top, a lower end connected to the pedestal, and the upright state, the remaining member constituting the carrier means, the hoisting machine 11 is mounted on the top of the column 2. The magnetic lifting assembly 14 secured by an electromagnet block 1401, solenoid 1402, D 1403 pulley 12 and the bail bolts, which is mounted on two guide rods (guide rods 4 and left and right guide rod 5), movable along the gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com