Jack anti-rotating easily-detachable reciprocating impact head of digger

An impact head, easy-to-remove technology, used in cutting machinery, earth-moving drilling, slitting machinery, etc., can solve the problems of low efficiency, easy falling off, and difficulty in cooling the cutting and cutting teeth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

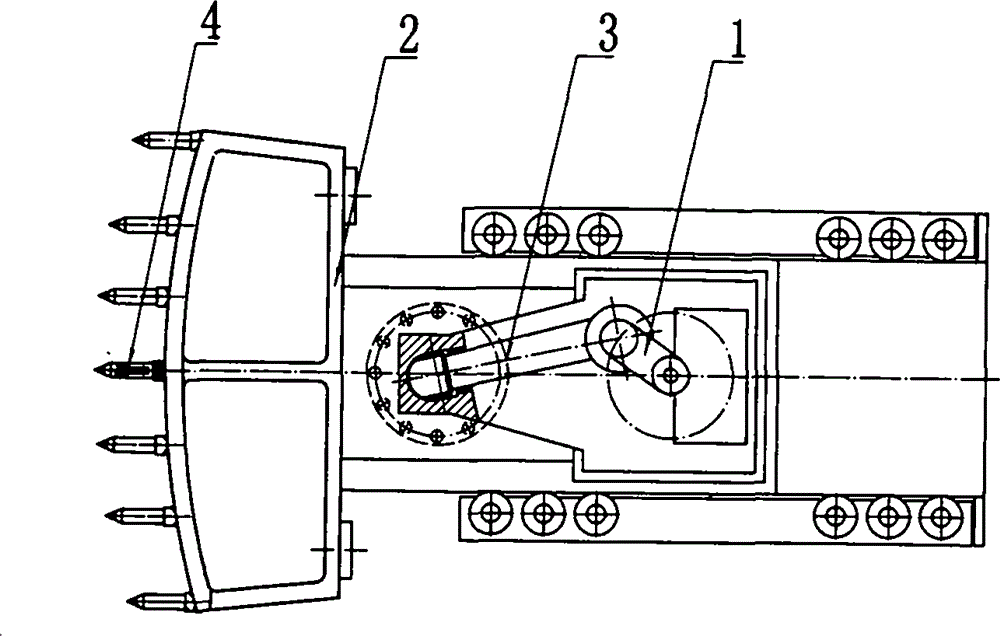

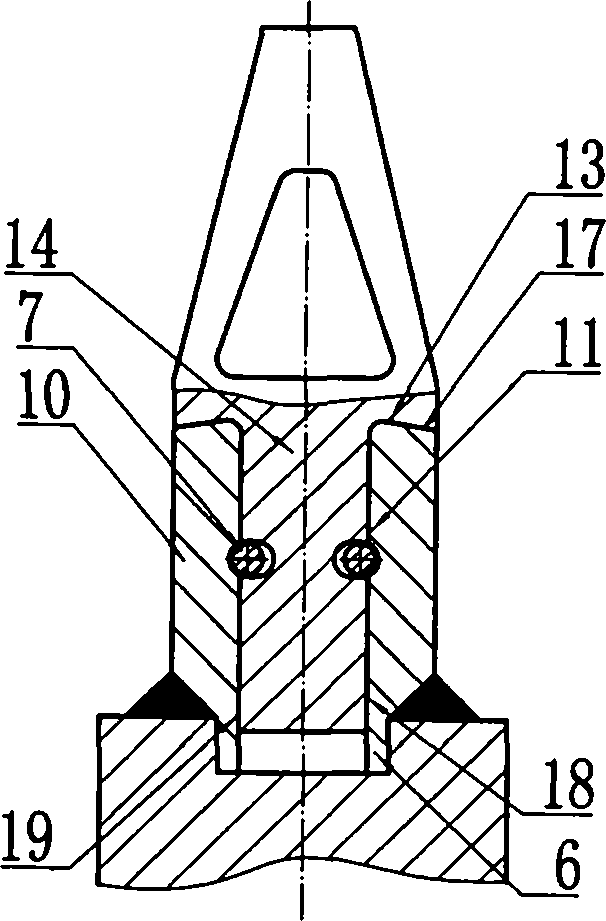

[0129] Figure 1 to Figure 4 It is the anti-rotation and easy-to-disassemble reciprocating impact head of the mining machine socket described in Embodiment 1: the reciprocating impact head 4 includes reciprocating impact teeth 5, fixing seats 6, etc., and also includes retaining springs 7, etc., and the tooth seat 10 includes tooth seat socket parts 11. The tooth holder 10 also includes a tooth holder shoulder 13, the reciprocating impact tooth 5 includes a punching tooth insert 14, etc., the reciprocating impact tooth 5 also includes a punching tooth 16, a punching tooth shoulder 17, etc. Above, the punching tooth shoulder 17 is arranged at the lower part of the punching tooth 16, and the reciprocating impact tooth 5 and the fixed seat 6 include a hole for setting the circlip 7, etc., and the circlip 7 is arranged in the hole to connect the fixed seat 6 and the reciprocating impact tooth 5, The circlip 7 bears the backward pulling force of the reciprocating impact movement, a...

Embodiment 2

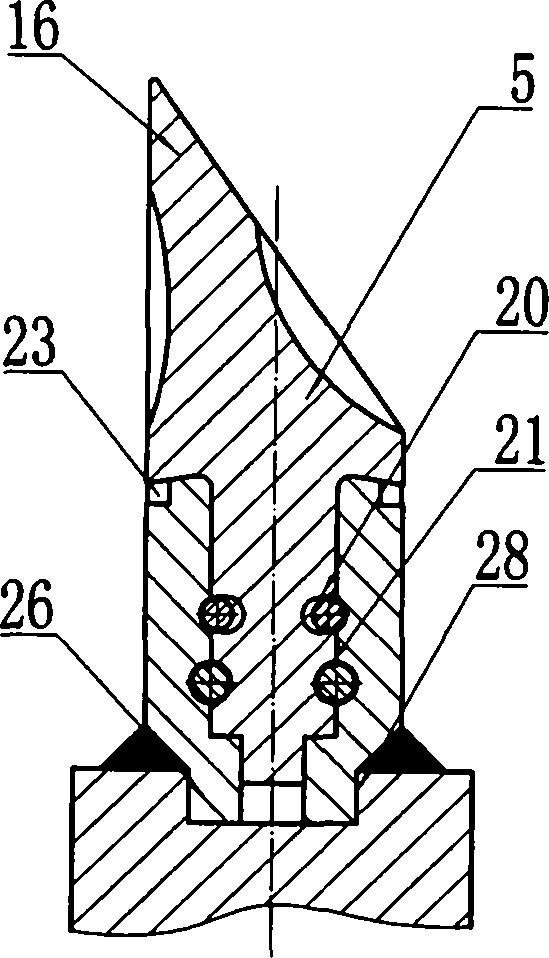

[0141] Such as Figure 5 to Figure 7 As shown, it is the anti-rotation and easy-to-disassemble reciprocating impact head of the excavator socket shown in Embodiment 2. The difference from Embodiment 1 is that the elastic pin 8 includes an elastic bayonet pin 29, and the tooth holder 10 is provided with a concave hole 30 The punching pin 14 is correspondingly provided with a tapered hole 31 matching with the concave hole 30 , and the elastic locking pin 29 is arranged in the tapered hole 31 and the concave hole 30 .

[0142] Correspondingly, tapered grooves or pin holes matching with the recessed holes 30 can also be provided on the punching teeth inserting post 14 .

[0143] The elastic bayonet pin 29 is also arranged in the tapered groove and the concave hole 30 or in the pin hole and the concave hole 30 .

[0144] Described elastic force pin 8 comprises elastic bayonet 29, and elastic bayonet 29 comprises lock head 32 and lock root 33, and lock root 33 rear portion is provi...

Embodiment 3

[0148] Such as Figure 8 As shown, it is the anti-rotation and easy-to-disassemble reciprocating impact head of the mining machine socket shown in Embodiment 3. The difference from Embodiment 1 is that the elastic pin 8 includes an elastic bayonet pin 29, and the tooth seat 10 is provided with The recessed hole 30, the reciprocating impact tooth 5 is correspondingly provided with a stepped hole 35 matching the recessed hole 30, the elastic bayonet pin 29 is arranged in the large hole of the stepped hole 35 and the recessed hole 30, and the elastic bayonet pin 29 includes a lock head 32 and Lock root 33, the rear portion of lock root 33 is provided with elastic body 34, and lock root 33 and elastic body 34 are arranged in concave hole 30, and lock head 32 is arranged in the large hole of step hole 35, when dismounting reciprocating impact tooth 5, use less than The brazing rod of the stepped hole 35 pushes the lock head 32 into the concave hole 30 from the small hole of the ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com