Pouring forming high life corundum mullite ladle lower nozzle brick and preparation method thereof

A casting molding, mullite brick technology, applied in the field of nozzle bricks, can solve the problems of loose structure, high carbon content, loss, etc., and achieve the effects of good absorption and dissipation, mitigation of damage, and good elastic strain energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

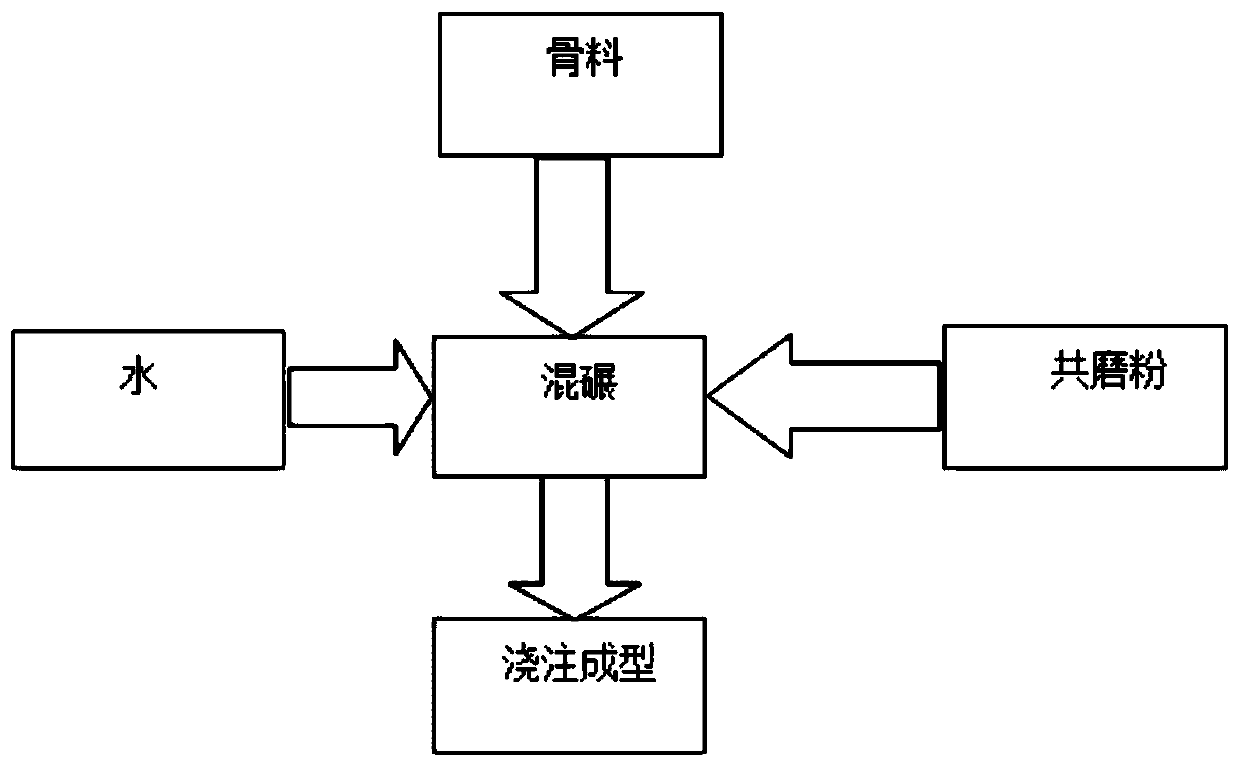

[0050] like figure 1 As shown in the process, the preparation method of the pouring-molded high-life corundum-mullite ladle nozzle brick in this embodiment includes the following steps:

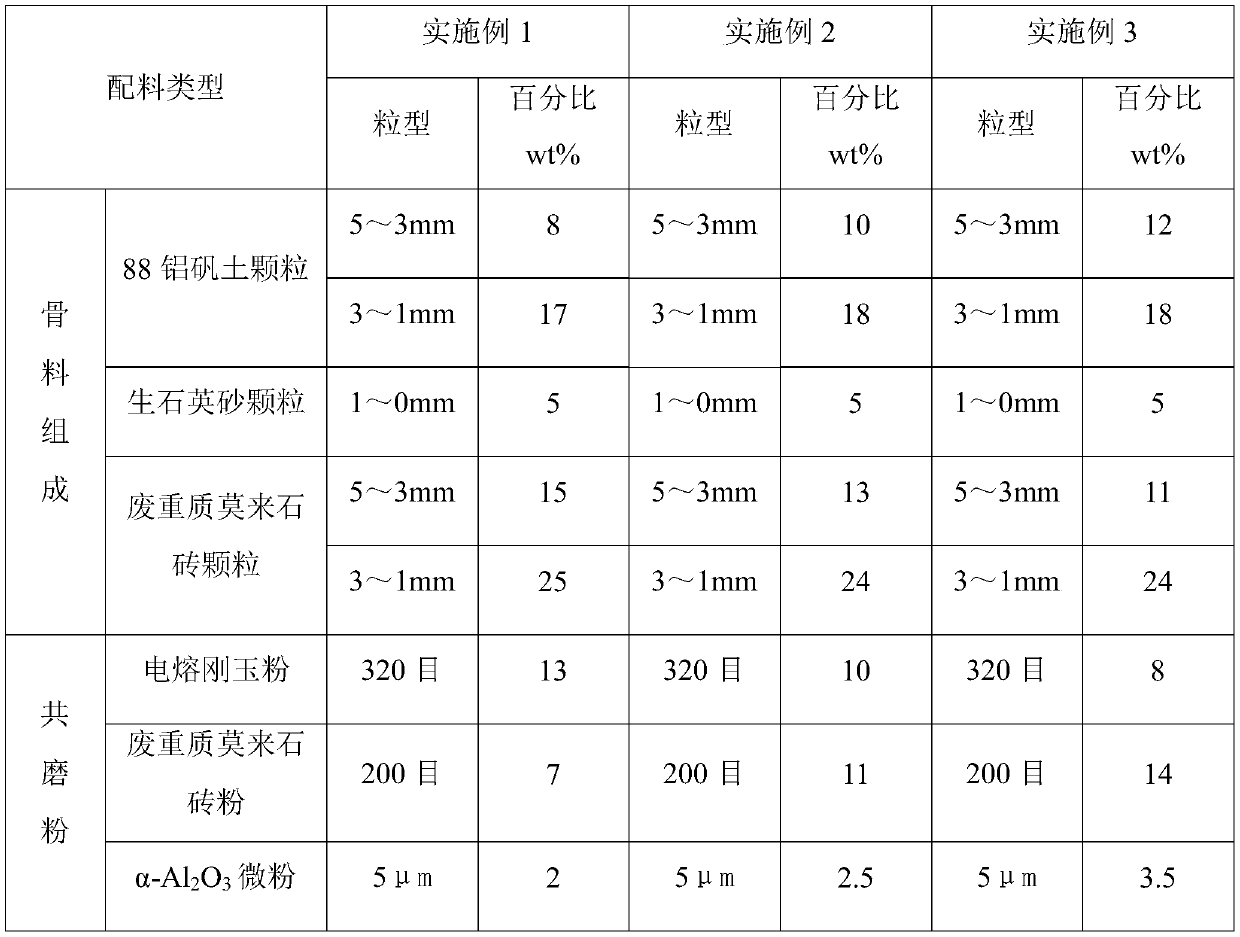

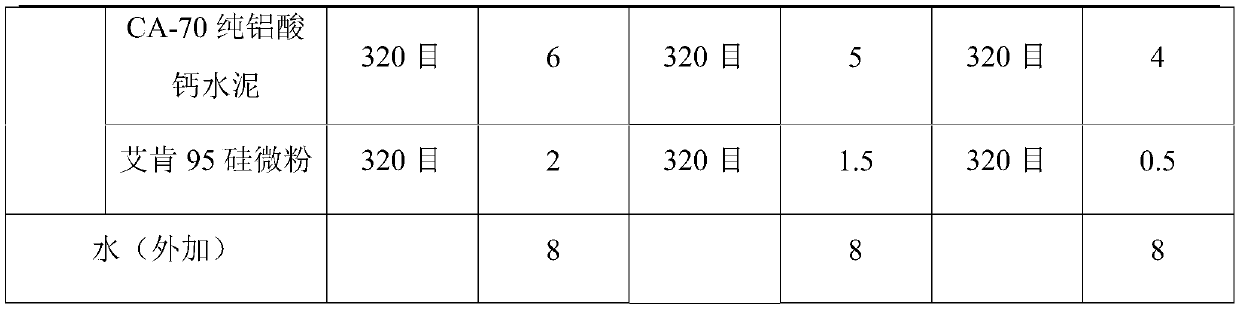

[0051] Step S101, according to the proportion by weight of the corundum mullite ladle drain brick raw material components, including aggregate and co-grinding powder, the raw material of the aggregate includes: 88 bauxite particles 25wt%, waste heavy mullite Stone brick recycled particles 40wt%, raw quartz sand particles 5wt%; co-grinding powder raw materials include: fused corundum fine powder 13wt%, waste heavy mullite brick regenerated fine powder 7wt%, α-Al 2 o 3 Micropowder 2wt%, Aiken 95 silicon micropowder 2wt%, CA-70 pure calcium aluminate cement 6wt%, the sum of the weight percentages of each raw material is 100wt%;

[0052] Fused corundum powder, regenerated fine powder of waste heavy mullite bricks, α-Al 2 o3 Micro powder, Aiken 95 silica powder and CA-70 pure calcium aluminate ...

Embodiment 2

[0057] The preparation method of the cast-molded high-life corundum-mullite ladle nozzle brick of this embodiment includes the following steps:

[0058] Step S101, according to the proportion by weight of the raw material components of corundum mullite ladle nozzle bricks, including aggregate and co-grinding powder, the raw materials of the aggregate include: 88 bauxite particles 28wt%, waste heavy mullite Stone brick regenerated particles 37wt%, raw quartz sand particles 5wt%; co-grinding raw materials include: fused corundum fine powder 10wt%, waste heavy mullite brick regenerated fine powder 11wt%, α-Al 2 o 3 Micropowder 2.5wt%, Aiken 95 silicon micropowder 1.5wt%, CA-70 pure calcium aluminate cement 5wt%, the sum of the weight percentages of each raw material is 100wt%;

[0059] Fused corundum powder, regenerated fine powder of waste heavy mullite bricks, α-Al 2 o 3 Micro powder, Aiken 95 silica powder and CA-70 pure calcium aluminate cement are co-ground, and mixed eve...

Embodiment 3

[0064] The preparation method of the cast-molded high-life corundum-mullite ladle nozzle brick of this embodiment includes the following steps:

[0065] Step S101, according to the proportion by weight of the raw material components of corundum mullite ladle nozzle bricks, including aggregate and co-grinding powder, the raw materials of the aggregate include: 30 wt% of 88 bauxite particles, waste heavy mullite Stone brick recycled particles 35wt%, raw quartz sand particles 5wt%; raw materials for co-grinding powder include: fused corundum fine powder 8wt%, waste heavy mullite brick recycled fine powder 14wt%, α-Al 2 o 3 Micropowder 3.5wt%, Aiken 95 silicon micropowder 0.5wt%, CA-70 pure calcium aluminate cement 4wt%, the sum of the weight percentages of each raw material is 100wt%;

[0066] Fused corundum powder, regenerated fine powder of waste heavy mullite bricks, α-Al 2 o 3 Micro powder, Aiken 95 silica powder and CA-70 pure calcium aluminate cement are co-ground, and m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com