Natural compound modified asphalt and preparation method thereof

A technology of composite modified asphalt and production method, which is applied to building components, building thermal insulation materials, buildings, etc., can solve the problems of affecting the water stability of the road surface, no great improvement in spalling resistance, spalling and detachment of asphalt and stone materials, etc. Achieve the effect of improving weather resistance and UV resistance, increasing durability, and reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

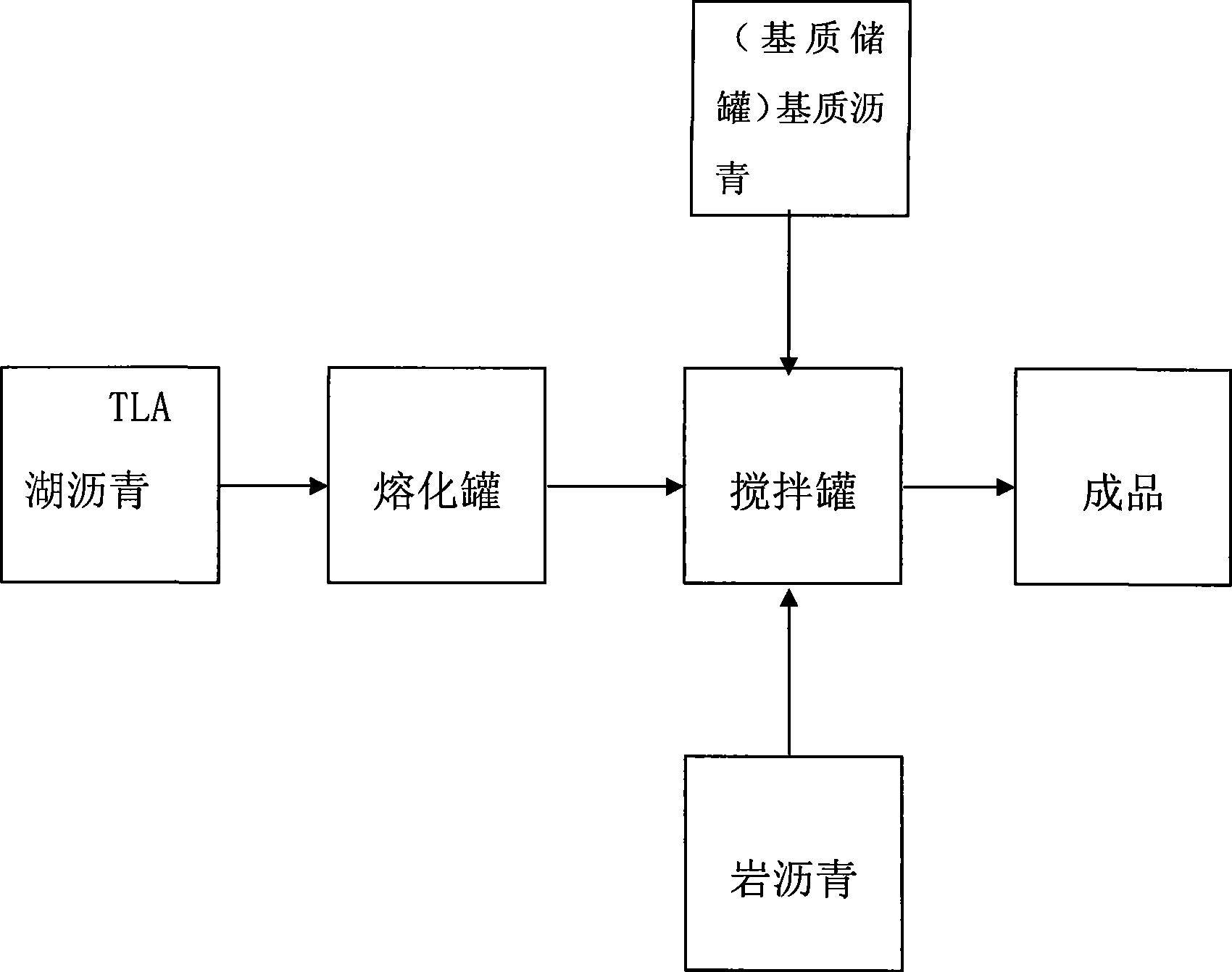

[0026] Embodiment 1: according to figure 1 The flow shown produces,

[0027] 1. Heat 7 tons (t) of AH-90 base asphalt in the base storage tank to 140°C to melt the base asphalt. The density of the base asphalt at 140°C is 1092Kg / m 3 .

[0028] 2. Put 3t of lake bitumen into the melting tank for complete melting at 195°C, and keep the temperature in the melting tank at 195°C after complete melting.

[0029] 3. Pump the base bitumen from the base storage tank into the mixing tank; then use the pump to drive the TLA lake bitumen from the melting tank into the mixing tank.

[0030] 4. Turn on the stirrer of the stirring tank and stir for 40 minutes while maintaining the temperature in the stirring tank at 165°C. While stirring, slowly and evenly add 4 tons of rock asphalt powder into the mixing tank to fully melt the rock asphalt powder.

[0031] 5. After the mixing is completed, TLA lake asphalt, rock asphalt and matrix asphalt are evenly mixed to become qualified natural com...

Embodiment 2

[0033] 1. Heat 9 tons of AH-70 base asphalt in the base storage tank to 130°C to melt the base asphalt.

[0034] 2. Put 1t of lake asphalt into the melting tank for complete melting at 195°C, and keep the temperature inside the melting tank at 195°C after complete melting.

[0035] 3. Pump the base bitumen from the base storage tank into the mixing tank; then use the pump to drive the TLA lake bitumen from the melting tank into the mixing tank.

[0036] 4. Turn on the stirrer of the stirring tank and stir for 20 minutes, while the temperature in the stirring tank is kept at 165°C. While stirring, slowly and evenly add 1t of rock asphalt powder into the mixing tank to fully melt the rock asphalt powder.

[0037] 5. After the mixing is completed, TLA lake asphalt, rock asphalt and matrix asphalt are evenly mixed to become qualified natural composite modified asphalt.

Embodiment 3

[0039] 1. Heat 3 tons of AH-110 base asphalt in the base storage tank to 140°C to melt the base asphalt.

[0040] 2. Put 7t of lake bitumen into the melting tank for complete melting at 195°C, and keep the temperature in the melting tank at 195°C after complete melting.

[0041] 3. Pump the base bitumen from the base storage tank into the mixing tank; then use the pump to drive the TLA lake bitumen from the melting tank into the mixing tank.

[0042] 4. Turn on the stirrer of the stirring tank and stir for 50 minutes, while the temperature in the stirring tank is kept at 170°C. While stirring, slowly and evenly add 3 tons of rock asphalt powder into the mixing tank to fully melt the rock asphalt powder.

[0043]5. After the mixing is completed, TLA lake asphalt, rock asphalt and matrix asphalt are evenly mixed to become qualified natural composite modified asphalt.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com