High-speed railway saline soil filler embankment structure and construction method thereof

A high-speed railway, saline soil technology, applied in the directions of roads, buildings, tracks, etc., to control the problems of subsidence and salt swelling deformation, save engineering investment, high stability and anti-deformation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

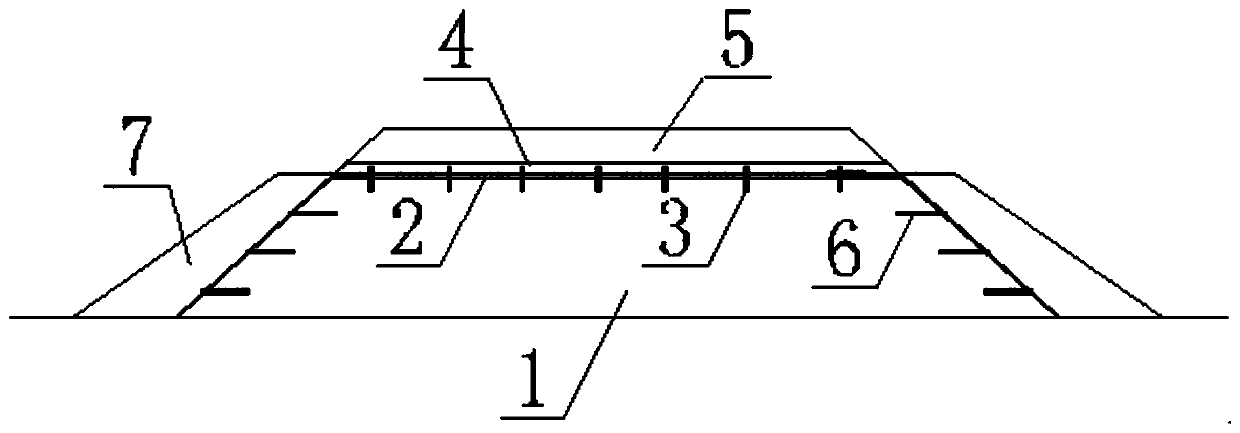

[0032] Such as figure 1 As shown, this embodiment provides a high-speed railway saline soil filling embankment structure, including an embankment superstructure 5, an embankment substructure 1, an insulation layer 2, a support member 3, an isolation device 4, an anti-seepage membrane 6 and a berm structure 7.

[0033] The embankment substructure 1 is filled with coarse saline soil, and the embankment substructure 1 is used for layered filling on the foundation.

[0034] The thermal insulation layer 2 is laid on the top of the embankment substructure 1, the thermal insulation layer 2 is provided with through holes, the number of support members 3 is at least two, and the support members 3 pass through the through holes, specifically, the support members 3 are geotechnical rods.

[0035] The isolation device 4 is located on the top of the insulation layer 2 and connected to the support 3. The isolation device 4 adopts an anti-erosion reinforced concrete structure. The embankmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com