Dispersive air brick

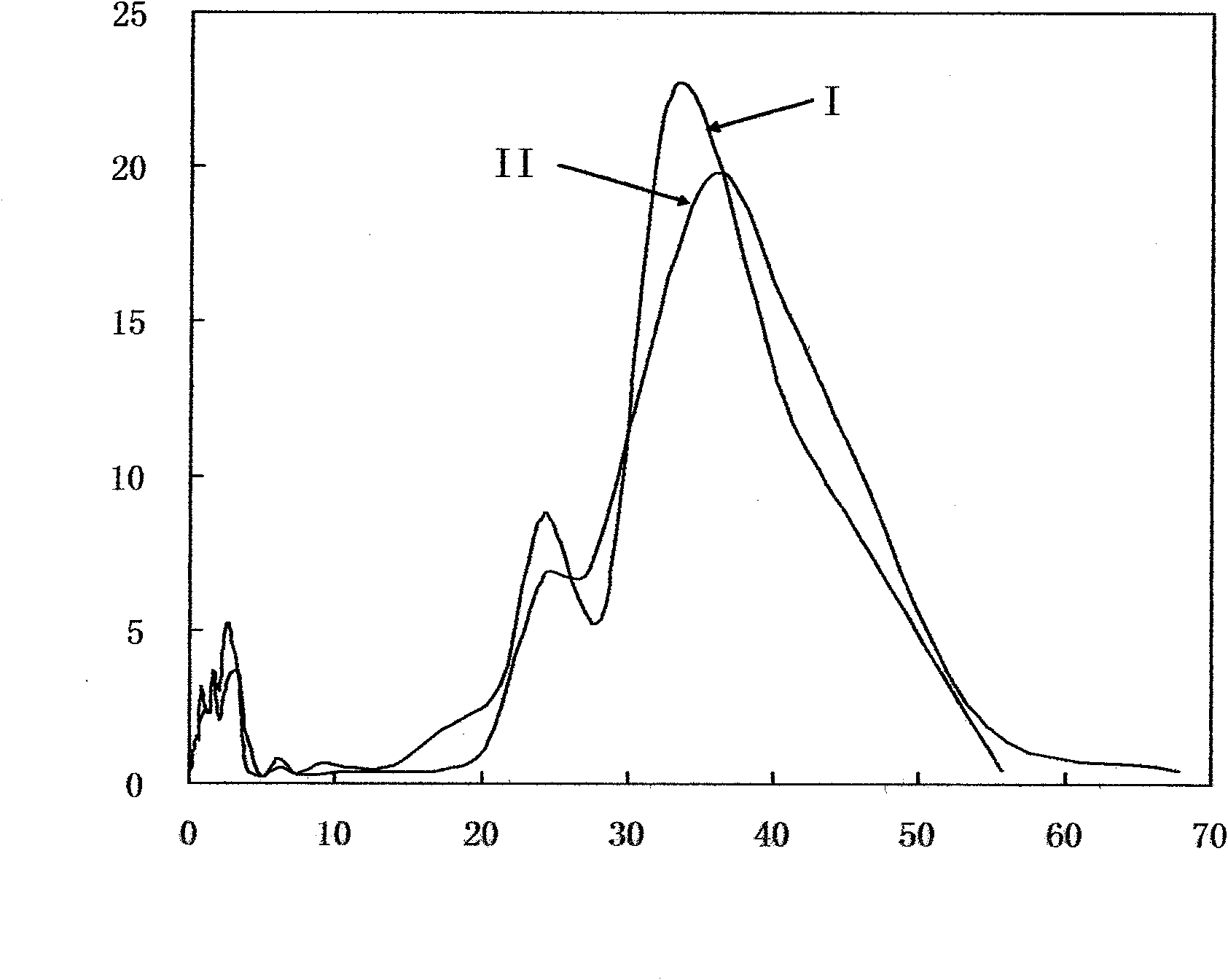

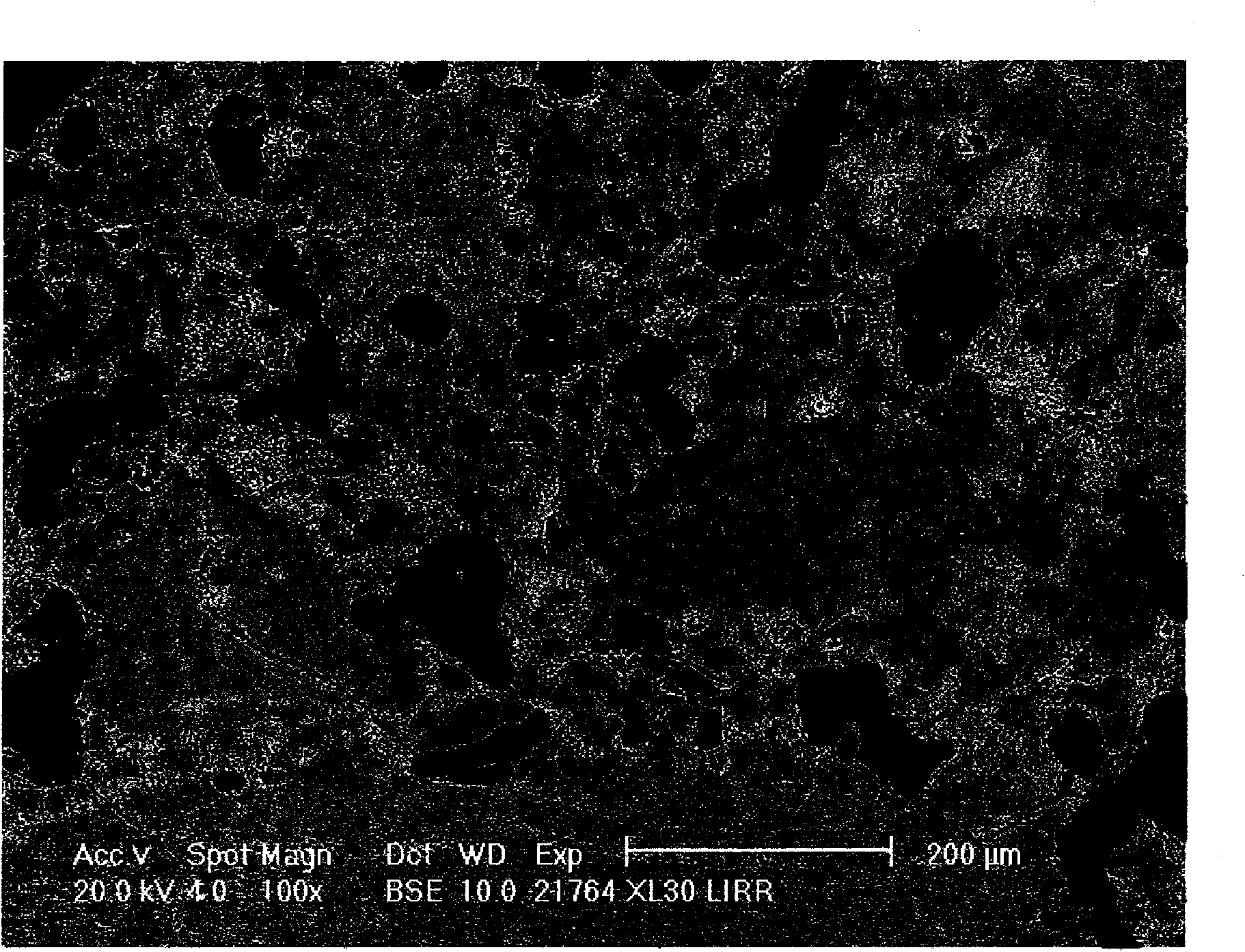

A technology of breathable bricks and air-entraining agent, applied in the field of breathable bricks, can solve the problems of large differences in green body, not too large bricks, and complicated processes, and achieves good anti-peeling performance, uniform distribution of pores, and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following non-limiting examples serve to illustrate the invention, but are not intended to limit it.

[0020] 1. Ingredients by weight percentage:

[0021] (1) Use aluminum raw materials as the main raw material

[0022] Tabular corundum 67%, kyanite 14%, activated alumina micropowder 5%, pure calcium aluminate cement 10%, microbubble air-entraining agent 1.2%, foam stabilizer 1.8%, water reducing agent ADS1 1%.

[0023] (2) Magnesium raw materials are used as the main raw material

[0024] Medium-grade sintered magnesia 75%, tabular corundum 13%, activated alumina micropowder 3%, ρ-alumina binder 5%, silica micropowder 1%, microbubble air-entraining agent 1%, foam stabilizer 1.7%, water reducing Agent FDN-30000.3%.

[0025] 2. Manufacturing process and performance testing method

[0026] After forming the ingredients according to the above ingredients, stir in the mixer for 3 minutes, then add an appropriate amount of clean tap water, and wet mix for 3 minutes....

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com