Environment-friendly aqueous long-life self-flowing repairing mix for converter and preparation method thereof

An environment-friendly, long-life technology, applied in the field of refractory materials, can solve the problems that pits or grooves cannot be repaired separately, long sintering time of repair materials, and reduced utilization rate of converters, etc., to achieve good resistance to molten steel erosion and high temperature performance , providing the effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The substantive features and advantages of the present invention are further clarified by comparing specific examples with asphalt-combined converter self-flow repairing.

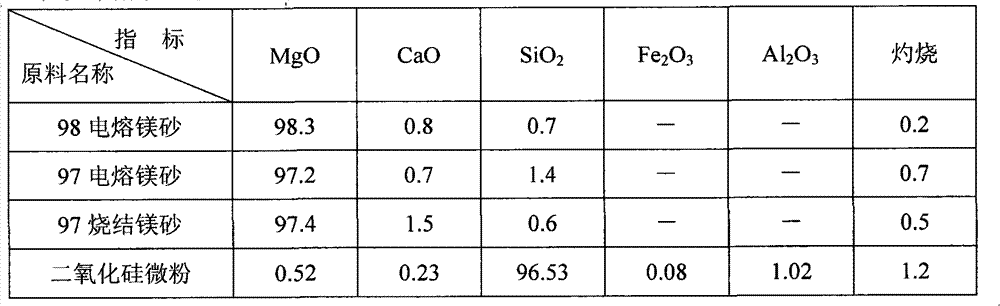

[0031] Host raw material and SiO described in the present invention 2 The chemical composition of the micropowder is shown in Table 1, and the specific composition of Examples 1 and 2 is shown in Table 2.

[0032] The chemical composition of the selected main raw material of the present invention of table 1:

[0033]

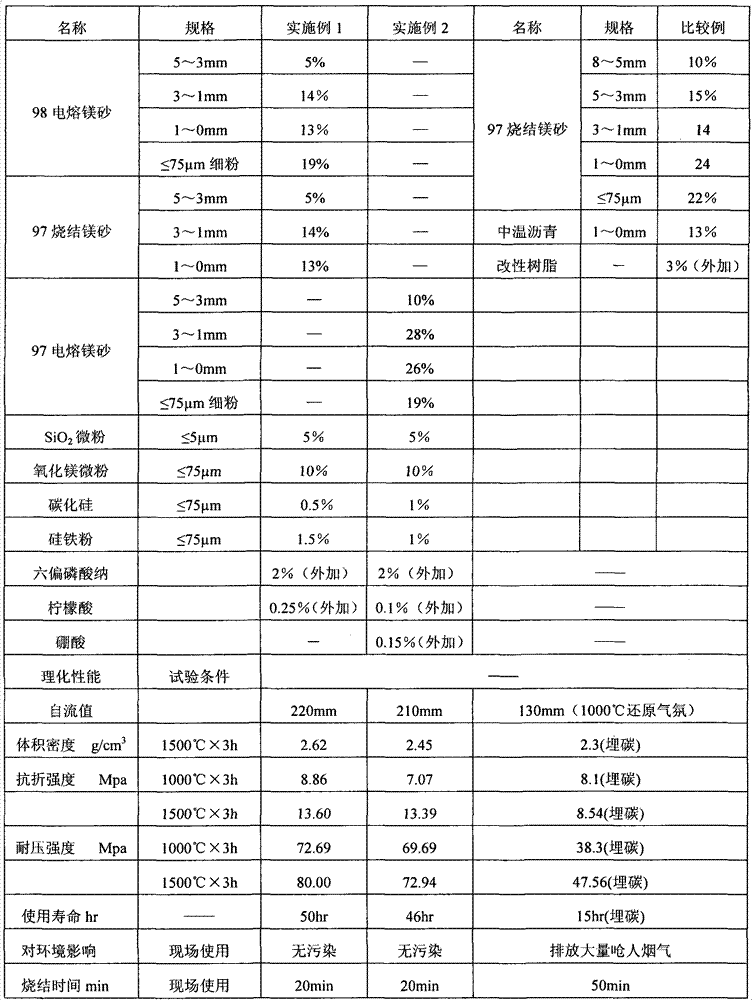

[0034] The composition of table 2 embodiment and comparative example and each performance index thereof.

[0035]

[0036] From the above examples, it can be concluded that the environmental-friendly water-based converter long-life self-flowing repair material of the present invention has good physical and chemical properties, and is better than asphalt-bonded converter self-flowing in terms of fluidity, sintering time, service life and environmental protection. Repair compound...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com