Novel aluminum-zirconium-carbon slide brick for flow control in metallurgy industry

An aluminum-zirconium-carbon sliding brick, a new type of technology, is applied in the field of iron and steel metallurgy, which can solve the problems of insufficient compactness of the sliding plate structure and short service life, and achieve considerable economic benefits, improved service life, and good heat-melting resistance.

Inactive Publication Date: 2006-12-27

ANSHAN CHOSUN REFRACTORIES

View PDF0 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0007] The present invention is a new type of aluminum-zirconium-carbon sliding brick for metallurgical flow control to solve the above problems such as insufficient density of the sliding board structure and short service life.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0032] Table 1 and Table 2 are the application examples of the present invention in product production.

[0033] The data in Table 1 and Table 2 shows that the porosity, compressive strength, erosion resistance, erosion resistance and other performance indicators of the embodiment (1-3) have been greatly improved compared with the skateboard product without adjusting the formula.

[0034]

[0035]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a new typed sliding brick in the iron smelting course, which comprises the following parts: 60-125 percent sintered or electric melting corundum, 10-20 percent sintered Al2O3 powder under 50 mum, 5-15 percent sintered or electric melting zirconium mullite, 5-20 percent sintered or electric melting zirconium corundum, 1-5 percent metal Si, 1-8 percent carbon material and 0.5-4.0 anti-oxidization agent.

Description

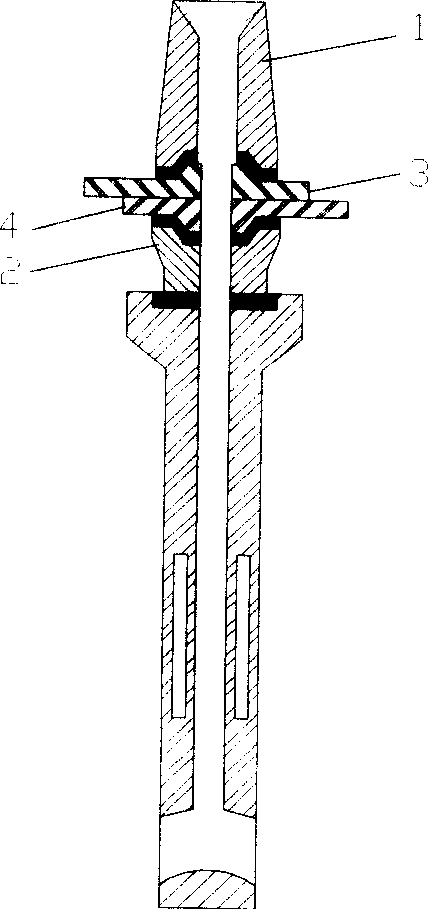

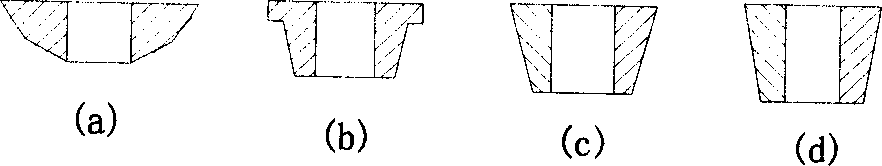

technical field [0001] The invention relates to the technical field of iron and steel metallurgy, and provides a new type of sliding brick used for flow control in iron and steel smelting. High stability and corrosion resistance; at the same time, it has good thermal shock stability, long service life, and no thermal cracks will appear during use. Background technique [0002] Slide material is an important functional element for flow control in iron and steel metallurgy process. During use, ordinary skateboard materials will crack due to uneven internal stress. The rapid change of thermal shock at the initial stage of molten steel pouring, the deformation of the mechanism for installing the slide plate, the uneven pressure on the working surface of the slide plate, the installation method of the slide plate, and the unevenness of the bottom of the ladle and tundish are all the reasons for the above cracks. When the content of oxygen and nitrogen in the molten steel exceed...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C04B35/66C04B35/10

Inventor 施岳明张小宁

Owner ANSHAN CHOSUN REFRACTORIES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com