Ltigh crystalline structure iolite mullite kiln, kiln refractory product and calcining technology

A technology for structural cordierite and mullite, which is applied in the field of kiln refractory products and roasting processes, and high crystal structure cordierite-mullite kiln furniture, can solve the problems of raw material quality, production conditions, production technology, quality control, etc. Remaining in the experimental stage and failing to find out the problems of large-scale production of high crystal structure cordierite-mullite kiln furniture, etc., to achieve excellent thermal shock resistance and no need for calcination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A cordierite-mullite kiln furniture and kiln refractory product with a high crystal structure, the raw materials include 50-80 parts by weight of main crystal phase materials, 20-50 parts by weight of bonded composite matrix materials, and the selected main crystal phase materials , combined with the total components of the composite matrix material reaches 100 parts by weight; then add an appropriate amount of crystal nucleating agent; wherein:

[0041] 1), the main crystal phase material is aluminum titanate, cordierite, mullite, andalusite aggregate, wherein aluminum titanate aggregate accounts for 0-20wt% of the main crystal phase material, and cordierite aggregate accounts for the main crystal phase material 20-40wt% of the main crystal phase material, mullite aggregate accounts for 20-40wt% of the main crystal phase material, andalusite aggregate accounts for 20-35wt% of the main crystal phase material, and the particle size of the above aggregate is less than 1mm;...

Embodiment 2

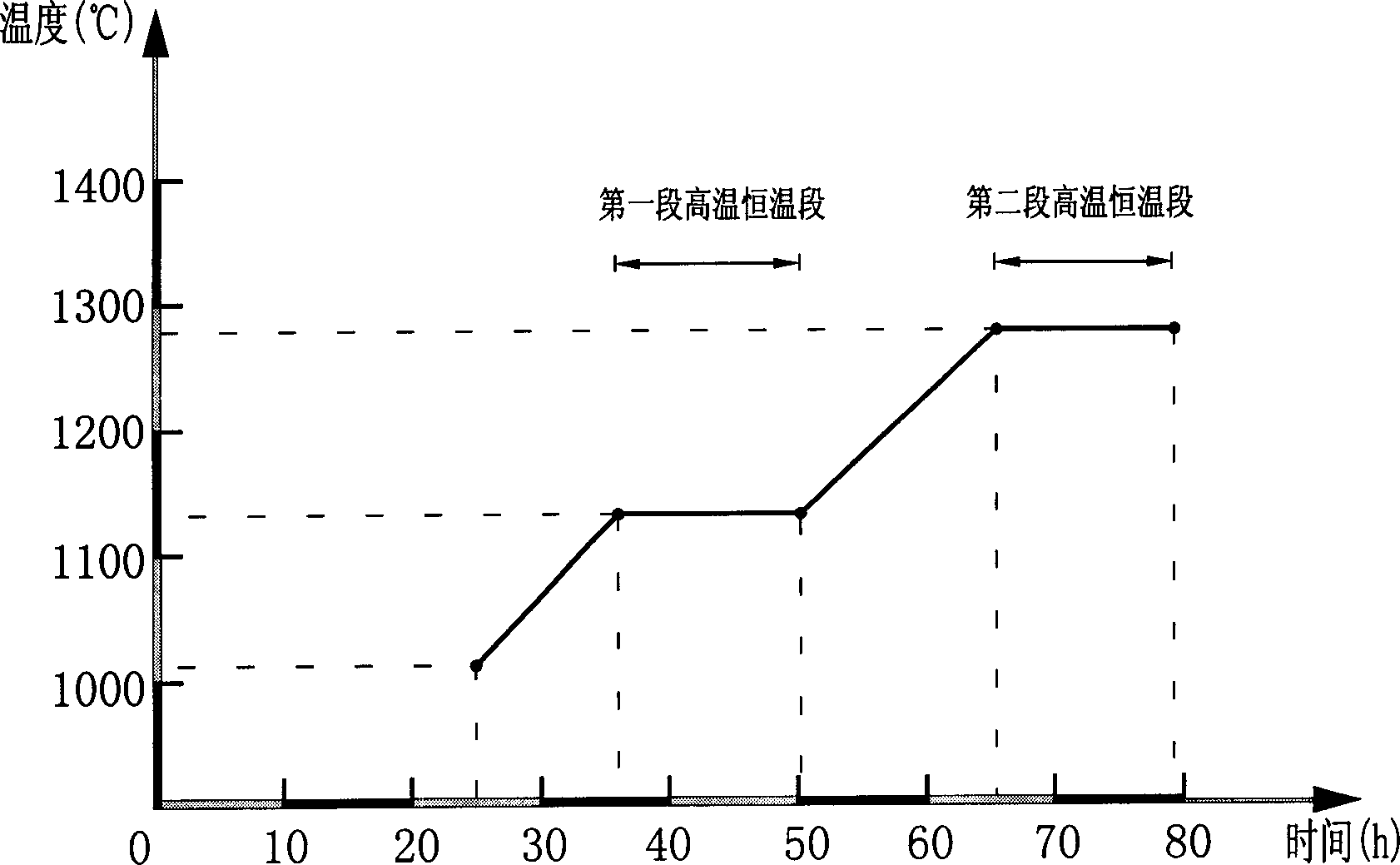

[0058] A roasting process for cordierite-mullite kiln furniture and kiln refractory products with a high crystal structure. The raw materials are selected from 50 to 80 parts by weight of main crystal phase materials and 20 to 50 parts by weight of bonded composite matrix materials. Select the main crystal phase material and combine the total components of the composite matrix material to reach 100 parts by weight; then add an appropriate amount of crystal nucleating agent; wherein:

[0059] 1), the main crystal phase material is aluminum titanate, cordierite, mullite, andalusite aggregate, wherein aluminum titanate aggregate accounts for 0-20wt% of the main crystal phase material, and cordierite aggregate accounts for the main crystal phase material 20-40wt% of the main crystal phase material, mullite aggregate accounts for 20-40wt% of the main crystal phase material, andalusite aggregate accounts for 20-35wt% of the main crystal phase material, and the particle size of the ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com