Modified cement mortar pavement patching material and pavement patching construction method

A pavement repair and cement mortar technology, applied in the field of pavement repair materials and civil engineering materials, can solve the problems of unsatisfactory cohesion and strength, long curing time, large water demand, etc. The effect of good workability and easy construction and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

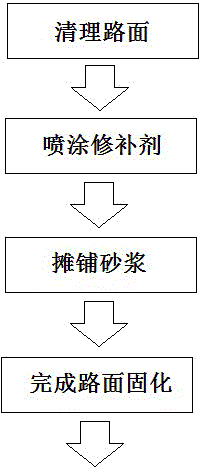

[0050] In this example, see Figure 1 ~ Figure 3 , for the construction method of repairing the severely pockmarked surface and the surface layer falling off, the construction process and conditions are as follows:

[0051] 1. Construction temperature: the construction environment temperature should not be too low, preferably 15-35°C;

[0052] 2. Preparation:

[0053] ①Clean the road surface: first clean the surface of the part to be repaired, remove dust and sundries, and remove the loose parts;

[0054] ②Surface pretreatment: After mixing component A, component B and water in a ratio of 1:1:1~1.5 (mass ratio), paint a layer on the cleaned surface, and the surface to be painted is composed of After the milky white becomes transparent, the repair work can be started;

[0055] ③Mixture preparation method: first mix the weighed components A, B and water evenly, then add the well-mixed cement and aggregates and mix well.

[0056] 3. Specific treatment measures:

[0057] The ...

Embodiment 2

[0072] This embodiment is basically the same as Embodiment 1, especially in that:

[0073] In the present embodiment, for the pavement repairing construction method of the processing of slightly pockmarked surface and newly repaired pavement microcracks, the construction process and conditions are:

[0074] 1. Construction temperature: this construction condition is identical with embodiment one;

[0075] 2. Preparatory work: this step is the same as in Example 1;

[0076] 3. Specific treatment measures:

[0077] The reference ratio of each component of the mixture of road repair materials is: 50kg of ordinary Portland cement 42.5, 90kg of sand, 12.5kg of A component, 12.5kg of B component and 9-12kg of water;

[0078] Treatment thickness: 3~5mm;

[0079] On-site construction method: Pour the mixture on the surface of the pretreated road surface, scrape it with a scraper, and then complete the road surface repair;

[0080] Pavement curing and strengthening time after repai...

Embodiment 3

[0082] This embodiment is basically the same as Embodiment 1, especially in that:

[0083] In this embodiment, for the pavement repairing construction method of the repairing of potholes, corner damage and bridge head expansion joint concrete, the construction process and conditions are:

[0084] 1. Construction temperature: this construction condition is identical with embodiment one;

[0085] 2. Preparatory work: this step is the same as in Example 1;

[0086] 3. Specific treatment measures:

[0087] The reference ratio of each component of the mixture of road repair materials is: 50kg of ordinary portland cement 42.5, 55kg of sand, 105kg of gravel, 12.5kg of A component, 12.5kg of B component and 0~7.5kg of water;

[0088] Processing thickness: greater than 30mm;

[0089] On-site construction method: pour the mixture on the pretreated pavement surface, smooth it with a trowel, and complete the pavement repair;

[0090] Pavement curing and strengthening time after repai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com